cuprolife®

For a sustainable future.

For a more sustainable future in construction.

With its 100 % share of recycled material, the cuprolife copper tube makes a sustainable difference, and thus makes a significant contribution to the advancement of building and construction as well as building services. In the future, unnecessary consumption of resources can be avoided and buildings rendered usable for many generations.

Recycling loop – 100 % recycled content.

Copper is unlimited – and it is also 100 % recyclable, making it a unique material for ecologically sustainable developments. The fact that the quality of copper is maintained at every stage is a decisive factor. Wieland is already in a position to offer well over 90 % recycled content in many semifinished products, depending on the material. In some cases, even 100 % is nowadays a reality. One prime example here is cuprolife.

Why settle for less when you can have 100 %?

100 % recycled content.

cuprolife consists of 100 % recycled copper.

100 % quality.

cuprolife ensures the highest quality standards because copper is infinitely recyclable without any adverse effects on quality.

100 % clean drinking water.

cuprolife guarantees a particularly high level of purity and the highest drinking water quality.

100 % sustainable action.

cuprolife enables more environmental protection in the building and construction industry, and makes a relevant contribution to sustainability.

As the starting point when verifying cuprolife, TÜV SÜD tested the procedure for calculating the 100 %

recycled content*.

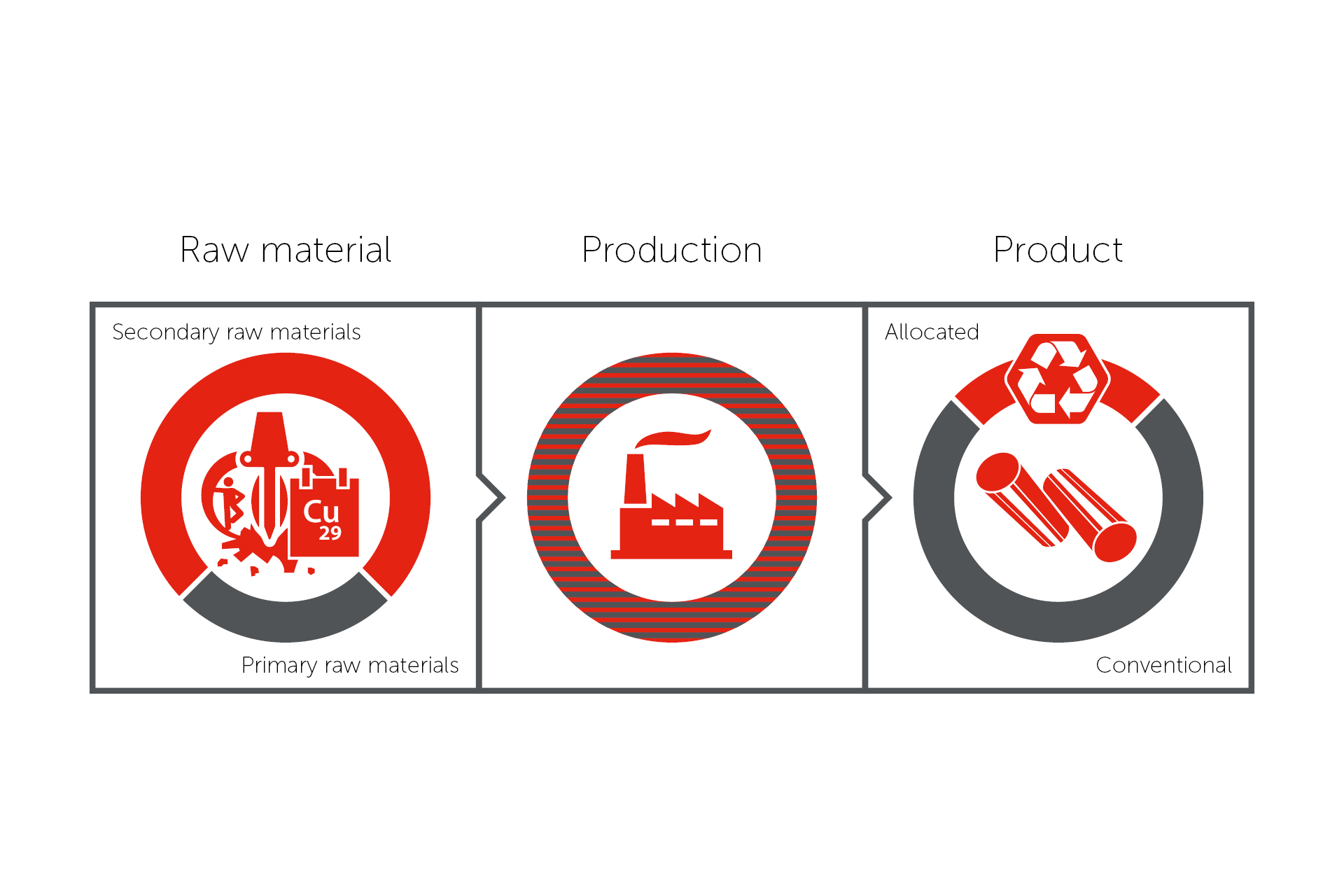

Wieland uses both primary and secondary raw materials when processing copper. The secondary raw materials are mainly scrap from the recycling loop. The decision to use raw materials that have already been an integral part of the cycle means this process will require fewer ores to be mined in the future. From the manufacturing viewpoint, raw materials of different origins are proportionately contained in the end product.

Verification Certificate TÜV Süd (De)

*Mass balance approach, based on ISO 14021, verified by TÜV SÜD.

100 % – A new milestone for Wieland.

The new standard in copper tubes: cuprolife®.

Thanks to cutting-edge manufacturing techniques, cuprolife tubes exceed even the highest requirements. Optimal efficiency and reliability are guaranteed along with an exceptional service life. cuprolife tubes are universally usable. cuprolife is permanently in stock and can be supplied in any size from 6 x 1 mm to 159 x 3 mm.

Fields of application

- Domestic hot and cold water supply

- Heating

- Gas

- Liquid gas

- Heating oil / biofuel oil B10

- Solar systems

- Rainwater

- Industrial compressed air

- Sprinkler systems

- Firefighting systems

Technical features

- 100 % recycled copper*

- Design according to EN 1057, quality assured

- Made of pure copper Cu-DHP With quality mark and DVGW certification: DV-7204AU2106 (6 to 159 mm outside diameter)

- Universal use in a range of finely differentiated dimensions

- Optimum availability and compatibility with a wide range of fittings

- Maximum operating temperature at 10 bar operating pressure: 250 °C (applies to dimensions up to DN 150)

- Fire resistance: EN 13501-1 – A1 (nonflammable)

- Dimensions according to DVGW GW 392 (6 to 159 mm) with closed tube ends

- For optimal drinking water hygiene