Efficient and ecological: innovative copper solutions for the automotive and electrical industries

Efficient and ecological: innovative copper solutions for the automotive and electrical industries

- Wieland presents its expanded product portfolio of high-performance alloys for miniaturized connectors and press-fit applications.

- With the material L96, Wieland offers an ecological alternative to copper beryllium.

- The digital alloy consultant AlloyWizard simplifies the search and selection of the most suitable material on the Internet.

From 13 to 16 November 2018, Wieland will be presenting its product range of copper and copper alloy strip for connectors at electronica in Munich in Hall B2, Stand 347. Due to the high strength combined with good electrical conductivity, high-performance alloys from Wieland can be used to miniaturize electromechanical components and thus reduce weight. This has a positive effect on the efficiency of end products and also on the emissions balance in the field of eMobility.

Connectors and stamping grids are used primarily in the automotive industry, connectivity solutions and consumer products (white and brown goods). There are also applications in mechanical and plant engineering as well as in the energy sector and renewable energies. They are also increasingly used in domestic installation technology and smart homes.

Product highlights at electronica

Wieland-B16 SUPRALLOY: Fine-grain bronze now available in press-fit thickness 0.64 mm. Supralloy bronzes from Wieland are ideal for miniaturized connectors in electronic applications. Due to the fine microstructure, the contact surfaces formed are significantly smoother, which is advantageous for subsequent electroplating with precious metals. SUPRALLOY fine grain bronze is now also available in press-fit thickness of 0.64 mm. The alloy is characterized by excellent formability in the press-fit zone and enables high spring forces (130 MPa higher yield strength than standard bronze).

Wieland-L96: the green alternative to CuBe2. With L96, Wieland presents another material for miniaturized connectors. With its combination of high tensile strength, resistance to thermal relaxation and excellent formability, L96 is the alloy of choice when it comes to alternatives to copper beryllium (CuBe). This is considered critical for health and the environment due to the toxicity of beryllium. L96 is not critical in this respect and also offers potential for optimised scrap recovery and thus improved recyclability.

Wieland-K55 R800: High temper strength now available in high thickness. The rolled product K55 R800 is now also available in high thicknesses up to 1.5 mm and offers particularly high spring forces for thick strips. It is therefore particularly suitable for terminal blocks in electrical engineering.

AlloyWizard: the digital alloy consultant on the Internet. With the AlloyWizard, Wieland presents its digital alloy consultant, which greatly simplifies material selection and enables rapid comparison of materials. Comparative displays in the form of spider diagrams and tables are available, as are graphics on resistance to thermal stress relaxation and bendability, see www.wieland-alloywizard.com.

To round off the product portfolio of strips, Wieland presents a wide range of tinning and electroplated strips in addition to special alloys.

All Wieland products are manufactured with state-of-the-art equipment, so that reliable supply, punctual delivery and consistently high quality are always guaranteed.

[Image] Hot-dip tinned strips

[Image] Connector made of high-performance alloy

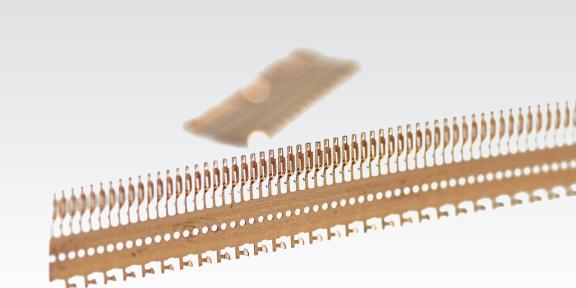

[Image] Press-fit connector made of SUPRALLOY

B16 SUPRALLOY | The perfect fit

Wieland K55 R800 I Effective spring forces