E-Mobility components

Wieland components for more efficient electric motors and batteries. The optimization of the battery as a key element of electric mobility has triggered a comprehensive increase in the efficiency of all components - from the rotor to the cabling and the drive train. As a long-standing and proven partner of the automotive industry, Wieland uses its extensive know-how and unique access to key technologies to develop advanced components for electric mobility.

Wide range of solutions

Wieland offers a wide range of solutions:

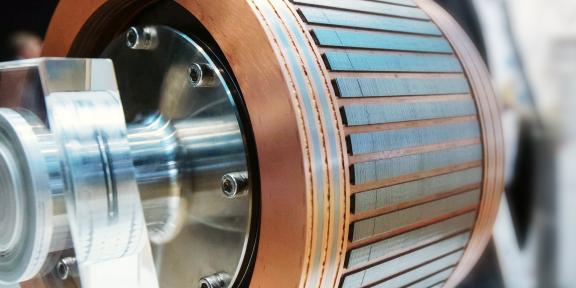

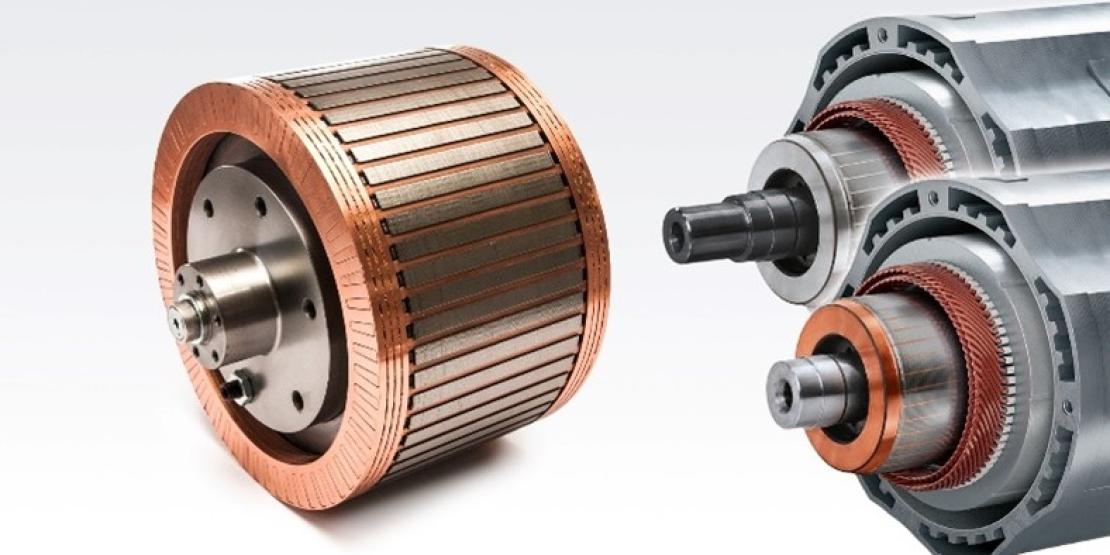

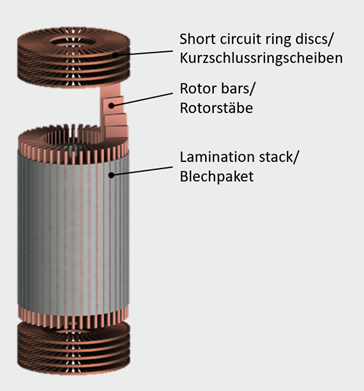

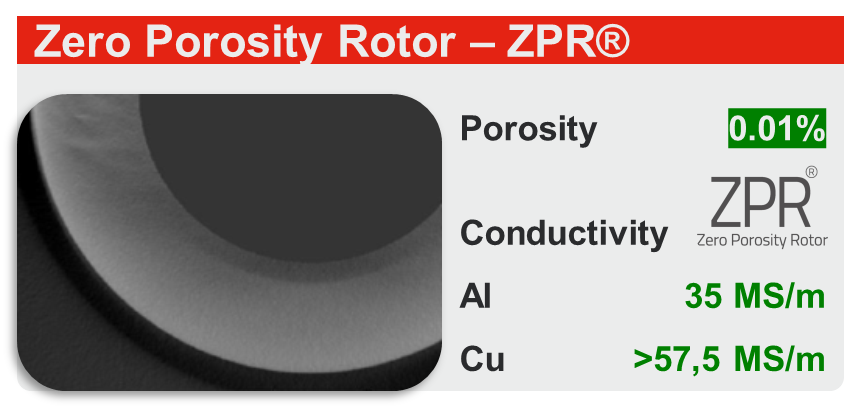

- Rotors – assembled and cast

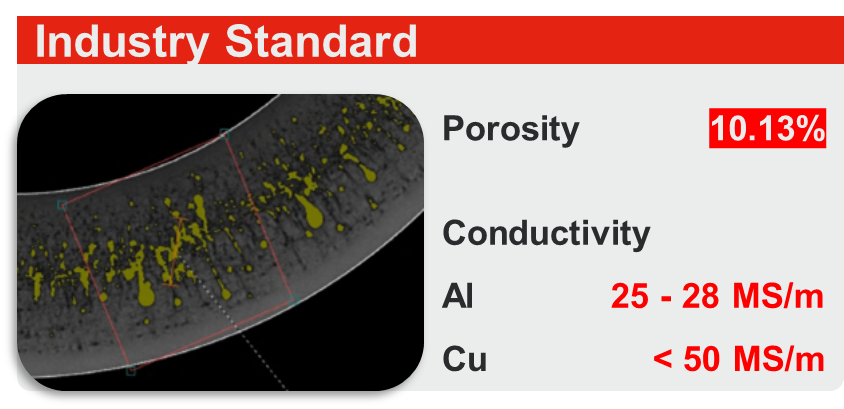

Wieland manufactures copper rotors and aluminum rotors for induction and asynchronous machines. Wieland's rotors can be both assembled or cast to meet the highest performance requirements. They offer excellent electrical conductivity and are ideal for applications where efficiency and reliability are critical. Our rotors not only offer high performance, but also durability and reliability in operation. - Compact connector units

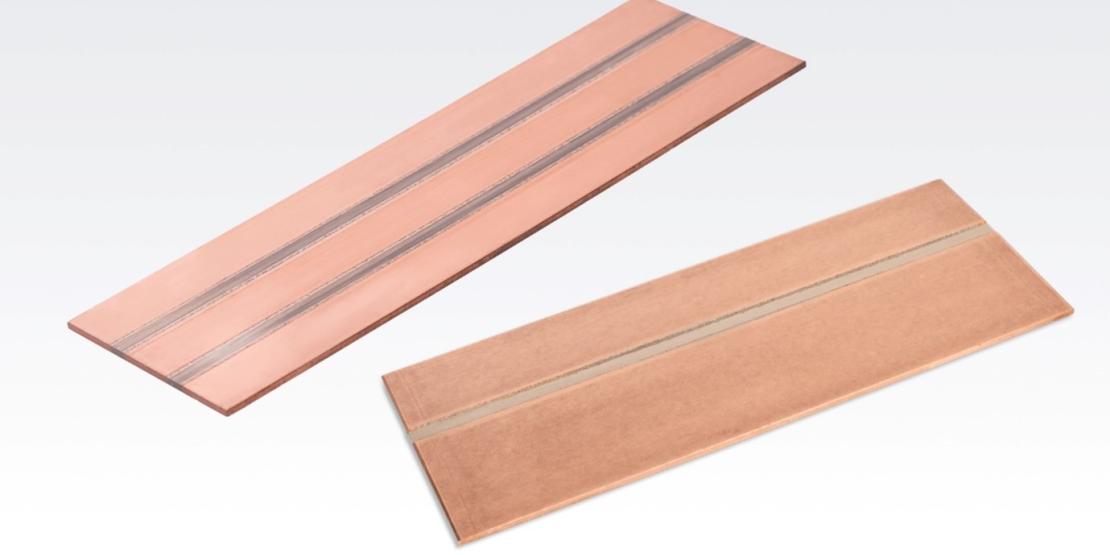

Our contacting components for stator windings are ideal for applications where space is limited. They enable efficient use of the available space and ensure a reliable electrical connection. - Overmolded busbars

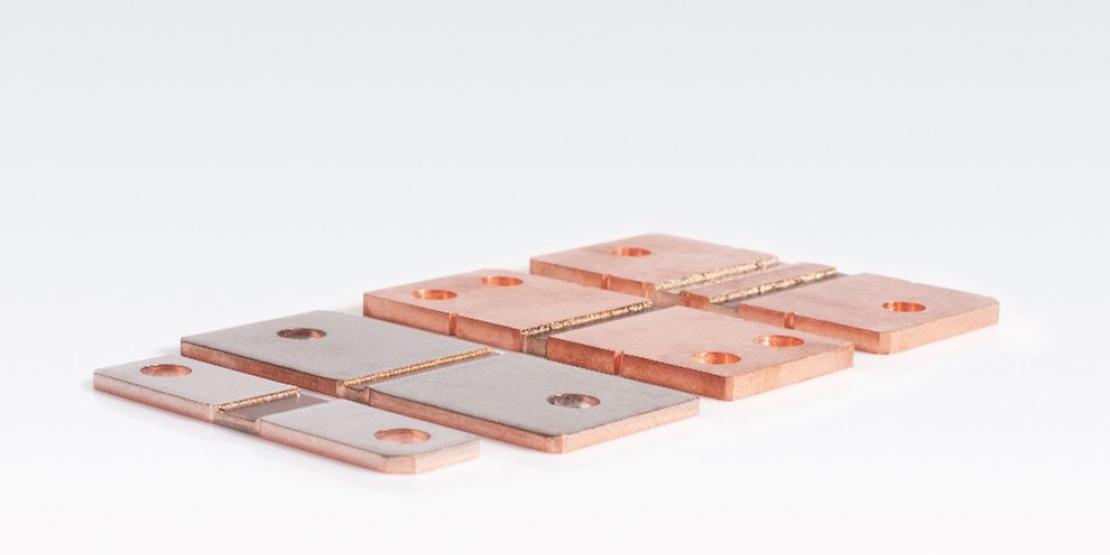

Our overmolded busbars offer a robust and reliable solution for electrical connection and power distribution in vehicles. They are designed for high currents and ensure efficient power transmission. - Shunts and shunt sensors for precise current measurement

Wieland offers precision resistors that are essential for high-precision measurements in electric motors and battery systems. Our products play an important role in precise current measurement and monitoring in electrical systems. They enable accurate measurement of currents and thus contribute to the safety and efficiency of electric vehicles and storage solutions.

Leading manufacturer

As one of the leading suppliers of semi-finished products in copper and copper alloys, including strips for connectors, semiconductor and electronic components, Wieland is a reliable partner from prototype development to series production.

Working with the best

Our products are developed in close cooperation with leading automotive manufacturers and underline our extensive know-how and leading market position. Through continuous innovation and a deep understanding of the requirements of electromobility, we set new standards in the industry.

Trust Wieland to lead your projects into the future of electromobility.

Our range of products

Our e-mobility components at a glance.

Wieland-Werke AG

This is our Wieland-Werke AG product portfolio.

Contact person

Get in touch - Our experts for e-mobility components

![]() E-Mobility Team

E-Mobility Team

General and product information

Wieland-Werke AG

Send email

Already know your search term? Then go ahead and use our full text search. You will get a list of all relevant results.