Heat exchangers

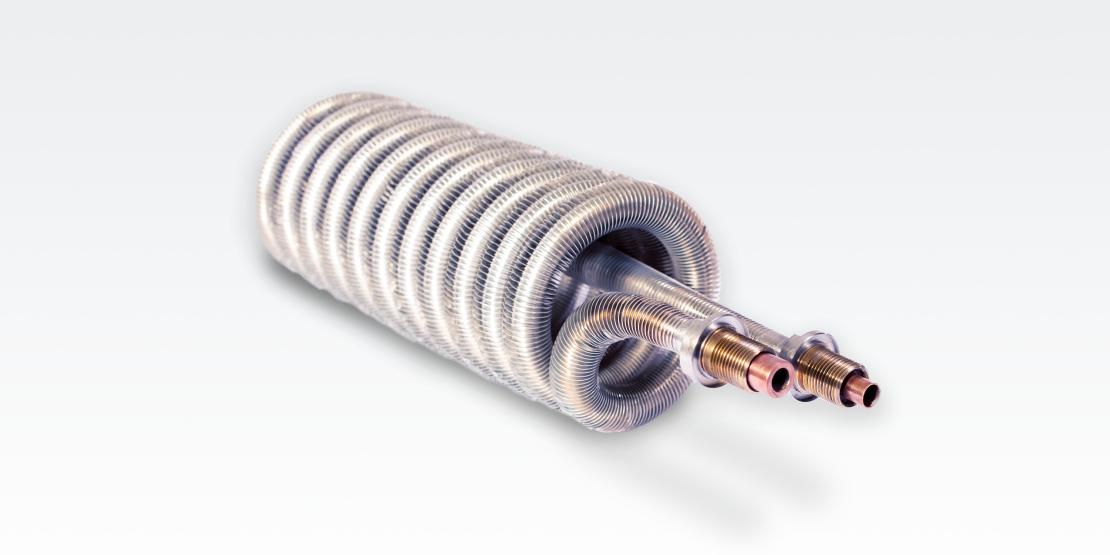

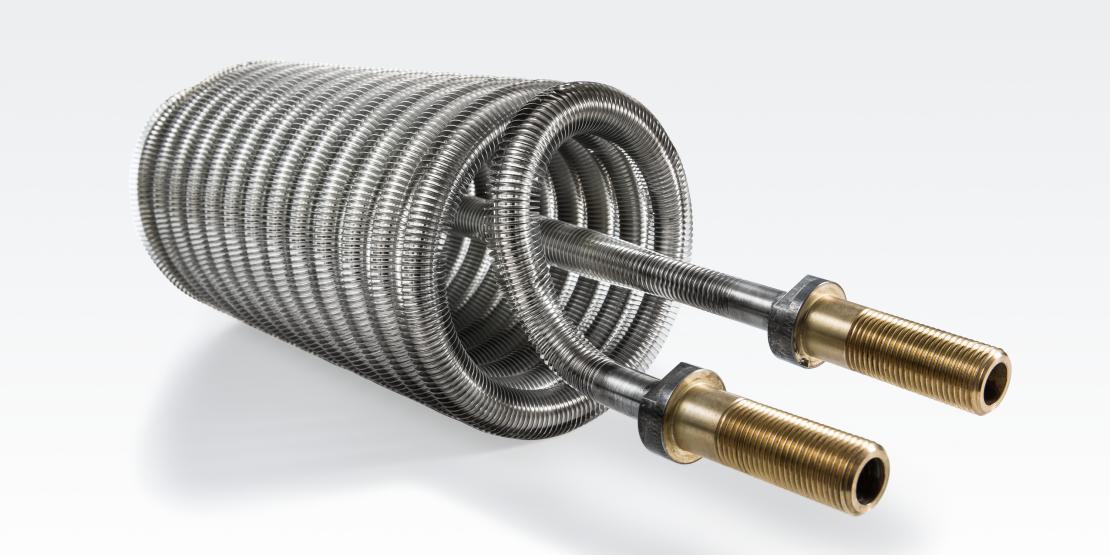

The right solution for any requirement. Heat exchangers made by Wieland Thermal Solutions are marked by their compact, yet highly robust design.

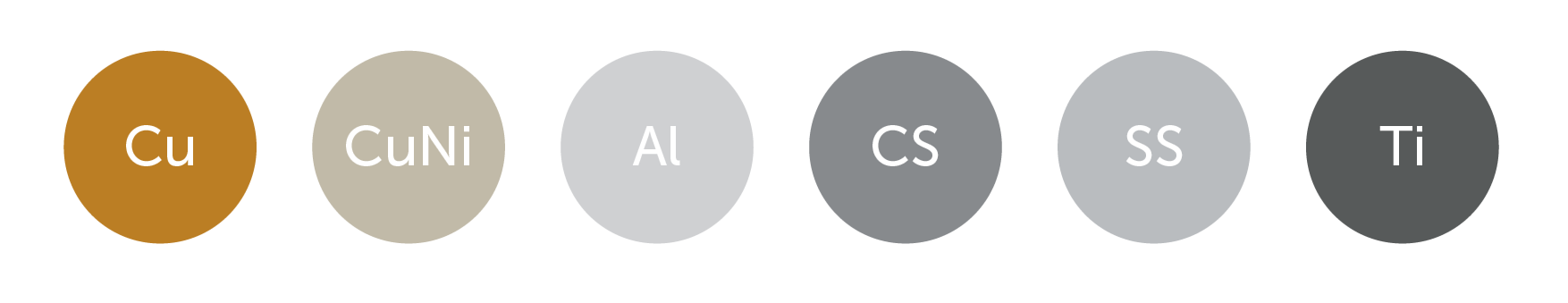

In addition to our in-stock finned tube coils, we also offer customized versions of our heat exchangers. Our expertise in heat transfer and forming technologies – coupled with modern design and construction methods – flows into all of our products.

Our range of products

Our heat exchangers at a glance.

Our complete product range

To show the product portfolio of a specific location, please select the company:

Contact person

Get in touch - Our experts for heat exchangers

![]() Andreas Moritz

Andreas Moritz

Heating Applications, Machinery & Plant Technology

Wieland-Werke AG

+49 731 944 1017

Send email

Already know your search term? Then go ahead and use our full text search. You will get a list of all relevant results.