Data sheet

Wieland Safety Heat Exchanger

Absolutely safe media separation with double wall tube

Wieland Safety Heat Exchangers consist of double-sided structured tubes made of copper Cu-DHP. The double-wall design ensures an absolutely reliable media separation and complies with the safety regulations of many European countries for heating drinking water with refrigerant.

Standard galvanic tin plating of the outer surface reduces the corrosion risk of galvanized steel pipes connected downstream.

| Type |

Max. condensation performance Q [kW)* |

Outer surface area [m²] |

Finned tube no. |

Tube length [mm] |

Volume refrigerant side [liters] |

di [mm] |

Dimensions [mm] |

Weight app. [kg] |

|||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Dmax | amax | e | G | ||||||||

| WRKS 9** | 3.0 | 0.84 | D-1132.12078-92 | 4,800 | 0.3 | 9.0 | 140 | 350 | 62 | 1/2" | 4.7 |

| WRKS 13** | 5.5 | 1.25 | D-1132.15080-92 | 6,000 | 0.7 | 12.0 | 147 | 410 | 62 | 3/4" | 7.5 |

| WRKS 18 | 7.5 | 1.82 | D-1135.18100-92 | 6,950 | 1.1 | 14.6 | 170 | 440 | 65 | 1" | 10.4 |

| WRKS 23 | 10.0 | 2.32 | D-1135.18100-92 | 8,750 | 1.4 | 14.6 | 170 | 540 | 65 | 1" | 12.9 |

Available from stock. Customized design possible on request.

*Refrigerant R134a and ∆T = 25K (difference between condensation and water temperature)

**Optional suitable for fluid group 1

Customized Design

With customized series Wieland Safety Heat Exchanger flex additional flexible designs are available with suitable connecting parts or different tubes like GEWA-safe plain.

On request brazed UNF-Fittings on both tube ends are possible (5/8“-18 UNF; 7/16“-20 UNF).

Advantages

- Safety through double wall media separation

- High resistance against corrosion

- Hygienic material copper with antimicrobial properties

Applications

- Condensation in domestic hot water heat pumps

- Heat recovery of supermarket refrigeration for drinking water

Operating range

- Max. operating pressure: 35 bar

- Max. operating temperature: + 130°C

Assembly Instructions

Wieland Safety Heat Exchanger is designed with one tube end with protruding inner tube, to install any warning system for leak detection. The gap at the other tube end can be closed by brazing.

To avoid vibration failure, the finned tube heat exchanger should be braced in the tank not only for transportation but also in operation.

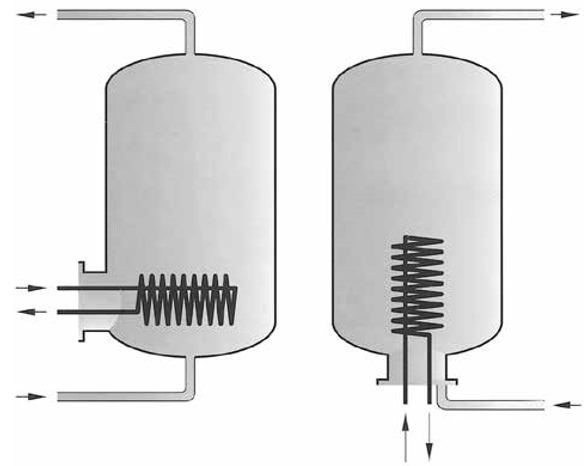

As a rule, the finned tube condenser is placed into the bottom part of the hot water tank. Its position may be horizontal or vertical.

The mounting to the storage flange is by means of a hexagon nut, EPDM-seal and hollow disk (included). When fixing the nut, it is necessary to counterhold at the fitting flats. Connected refrigerant pipes should be soldered to the pipe ends and fully absorb vibrations. A muffler should be mounted where the refrigerant vapour enters.

Electric insulation

Enameled hot water tanks are usually fitted with magnesium or impressed-current anodes to protect inadequately coated areas of the steel vessel against pitting corrosion. To maintain this protective effect, we recommend the use of insulation sets to ensure electrical separation of the heat exchanger from the storage tank. Retrofitting of hot water storage tanks is possible at any time.

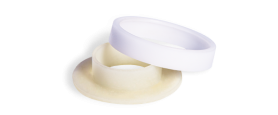

Insulating set F

The insulating set F (for flange mounting) consists of an insulating sleeve and an insulating ring. For an outside seal it is fitted between the heat exchanger and the storage tank flange as shown in the figure. Alternately a sealing from the inside is possible. If the flange is less than 8 mm thick, a distance washer (not supplied with the set) should be positioned between the hollow disk and the hexagon nut. Insulating sets are accessories and are supplied on request, two sets are required per heat exchanger.

| Part no. | Description | Material |

|---|---|---|

| 1 | Finned tube GEWA-D | Cu-DHP | K21 |

| 2 | Connection | CuZn21Si3P | SW1 |

| 3* | Insulating sleeve | PA |

| 4** | O-ring | EPDM |

| 5* | Insulating ring | POM-CE |

| 6 | Hollow disk | CuZn40Pb2 | Z48 |

| 7 | Hexagon nut | CuZn40Pb2 | Z48 |

* not supplied with the set | max. operating temperature: + 95°C

** max. operating temperature: + 130°C | do not use grease containing mineral oil

Quality Assurance

Responsibility begins with a high standard of quality. As the first company for semi-finished products in Europe, we have been on the path to certified quality management since 1987.

Today, we have DIN EN ISO 9001:2015 certifications for all producing plants, and our testing laboratories in Ulm and Vöhringen are additionally accredited to DIN EN ISO/IEC 17025:2018.

Pressure Equipment Directive

Safety heat exchangers correspond with the Pressure Equipment Directive 2014/68/EU. These heat exchangers are leak-tested with an overpressure of 50 bar. On the refrigerant side, they are cleaned in accordance with DIN 8964, dried, filled with nitrogen and sealed with plastic caps.

Your contact for heat exchangers

Wieland Thermal Solutions

Heat exchangers