Rods and sectional rods

The right alloy, geometry, and strength – precise and efficient: simply Wieland. Rods and profiled rods are used in a wide range of applications, extending over forged sanitary fittings, lock cylinders and turned parts for machine construction. You can choose from a virtually unlimited number of sizes and geometries.

Special alloys tailored to your specific application are recommended by our Applications Engineering experts.

Our range of products

Our rods and sectional rods at a glance.

Wieland Metal Services Germany GmbH | Kornwestheim

This is our Wieland Metal Services Germany GmbH | Kornwestheim product portfolio.

Rods

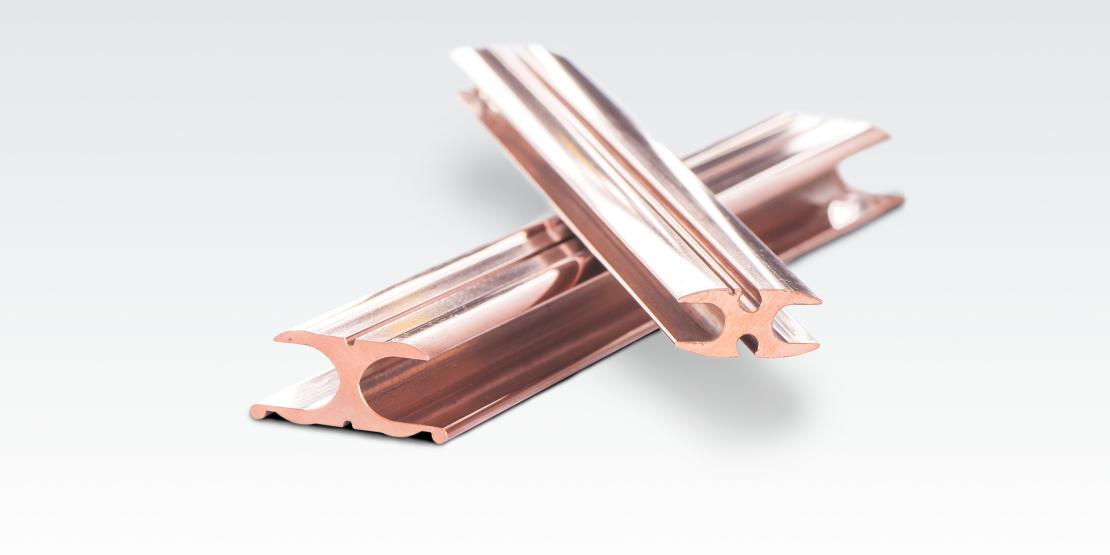

Sectional rod

Forging Stock

| Wieland | EN Designation | EN No. | ASTM UNS-No. |

|---|---|---|---|

| Elmedur B2 | CuBe2 | CW101C | C17200 |

| Elmedur HA | CuCoNiBe | CW103C | ~C17500 |

| Elmedur HC | CuNi2Be | CW110C | C17510 |

| Elmedur NCS | CuNi2SiCr* | ~CW111C* | C18000 |

| Elmedur X | CuCrZr | CW106C | C18150 |

| Elmedur Z | CuZr | CW120C | C15000 |

| Wieland | EN Designation | EN No. | ASTM UNS-No. |

|---|---|---|---|

| High Density (HD) | - | - | - |

| Molybdän (Mo) | - | - | - |

| Molybdän-Lanthan (ML) | - | - | - |

| Niob (Nb) | - | - | - |

| Rhenium (Re) | - | - | - |

| Tantal (Ta) | - | - | - |

| Titan (Ti) | - | - | - |

| Titan-Zirkon-Molybdän (TZM) | - | - | - |

| Wolfram (W) | - | - | - |

| Wolfram-Kupfer (TUCO) | - | - | - |

| Wolfram-Rhenium | - | - | - |

| Zirkonium (Zr) | - | - | - |

| Wieland | EN Designation | EN No. | ASTM UNS-No. |

|---|---|---|---|

| Elmedur NCS | CuNi2SiCr* | ~CW111C* | C18000 |

| Elmedur X | CuCrZr | CW106C | C18150 |

Wieland hot stamping rods

Good forging results can be obtained only when all links in the process chain have been matched to each other to the optimal effect. With Wieland hot stamping rods you are offered a forging stock which comprehensively fulfils these requirements. Your benefits: uniform dark surface for reproducible processing properties, tight diameter tolerances in the drawn size range, and hence precise configuration of the slug weight.

Materials

| Wieland | EN Designation | EN No. | ASTM UNS-No. |

|---|---|---|---|

| Elmedur B2 | CuBe2 | CW101C | C17200 |

| Elmedur HA | CuCoNiBe | CW103C | ~C17500 |

| Elmedur HC | CuNi2Be | CW110C | C17510 |

| Elmedur NCS | CuNi2SiCr* | ~CW111C* | C18000 |

| Elmedur X | CuCrZr | CW106C | C18150 |

Related topics

This might be of interest to you

Already know your search term? Then go ahead and use our full text search. You will get a list of all relevant results.