Die-Cast Zero Porosity Rotors

Efficient rotors for e-mobility

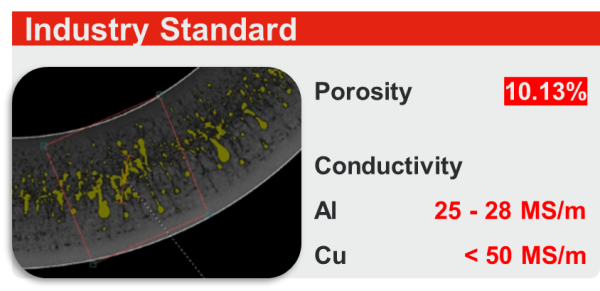

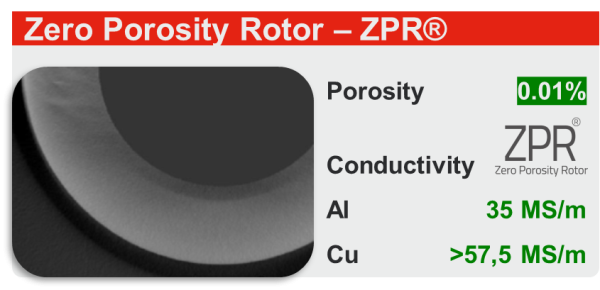

Wieland eTraction Systems has succeeded in developing the Zero Porosity Rotor - ZPR® using our unique and patented Laminar Squeeze Casting technology. We outperform the industry in both copper and aluminum rotors as shown in the CT scans below.

The laminar squeeze casting process developed by Wieland eTraction Systems is designed to cast rotors with no porosity, called Zero Porosity Rotors (ZPR). Simultaneous filling of all slots are guaranteed by a special gating system. This enables cast new, thinn and special slot geometries. The filling process is ascending and laminar. This is in contrast to conventional turbulent filling. Cost-effective production is possible because labor requirements are only slightly different from conventional casting.

Lower flow rates keep the molten metal in the gate for longer periods of time. This makes it easier to recycle the molten metal. Solidification from the laminar core to non-critical areas is controlled by active thermal management. Laminar squeeze casting fills all slots simultaneously. Contaminated melt fronts are directed into the overflow.

The casting process for conventional rotors has a problem: as the melt transitions from liquid to solid, there is a loss of volume called solidification shrinkage. To compensate for this shrinkage, companies must use high speed and pressure, which cause a turbulent filling.

Trapped gas combined with shrinkage produces high overall porosity. Die-cast rotors can not achieve porosities significantly lower than 10%. This is above the requested amount.

The Wieland eTraction Systems ZPR Rotor is a quality leader in the global rotor manufacturing industry. It outsmarts the problems associated with conventional rotors. The benefits of a Zero Porosity Rotor are

- Unique product quality

- Stable process capability

- Significantly improved electrical conductivity

- Increased efficiency of your electric motor

Further Information

Read more about the benefits of the Zero Porosity Rotor in the May 2023 issue of International Transport Manufacturer.

For a more in-depth technical look at the scientific background of the ZPR, you can request a copy of our brochure here:

For more information

about the ZPR, its benefits and how it can be applied in your field, please contact us for a personal consultation: