A shining outlook – with solutions from Wieland

Whether for protecting the input stock or the finished product itself or for optimizing engineering properties, Wieland has the surface needed. Our knowhow covers both semi-finished and finished parts.

A component’s surface can have considerable effects on this component’s functionality. If complex decorative parts are to be made without problems from semi-finished products, these should, for example, be free of scratches and stains. Among other materials, tin plated strip is used in the production of plug connectors for sustained electrical contact. Special tinning qualities serve to optimize the push-in and pull-out forces for plug connectors. And special leadframe surfaces enhance reliable bondability for semiconductor applications. On the other hand, an ultra thin coating of SiO2 can protect finished components against corrosion. We deliver our brass bars with a uniform, homogeneous surface for the optimal hot forming properties.

Our offer tailored to your requirements

We deliver those surfaces your application needs. In the case of tricky issues, complex components, or challenging process steps, our experts at Technical Marketing work together with our customers to find the optimal surface. Whether this is for strip, sheets, rods, or wires or for subsequent protective coatings on components. Our knowhow enables us to tailor the surface precisely to your wishes.

- Tinning according to the requirements the component must fulfil: whether for optimizing the push-in and pullout forces, the soldering properties, or corrosion resistance.

- The surface quality of bare strip depends greatly on the roughness. Whether standard values or special qualities for special applications: We recommend the matching surface quality – not too high, not too low.

- For the manufacturer of end products, protective-lined rolled products are a simple and effective contribution towards greater productivity. What is important for decorative components: No matter whether uniform colouring or particularly smooth surfaces – you save subsequent production operations.

- Subsequent protection, when the components are coated with a protective layer of silicon dioxide (SiO2). Stable dimensions and unchanged thermal properties of the components, and this not only on copper, but on virtually all metals and metal alloys. And the best of all: Also complex surface textures and even internal surfaces can be treated.

- Optimal result for the manufacture of forged parts. For our surface quality allows a low press temperature, safeguards operations free of disruption, and minimizes wear.

Learn more

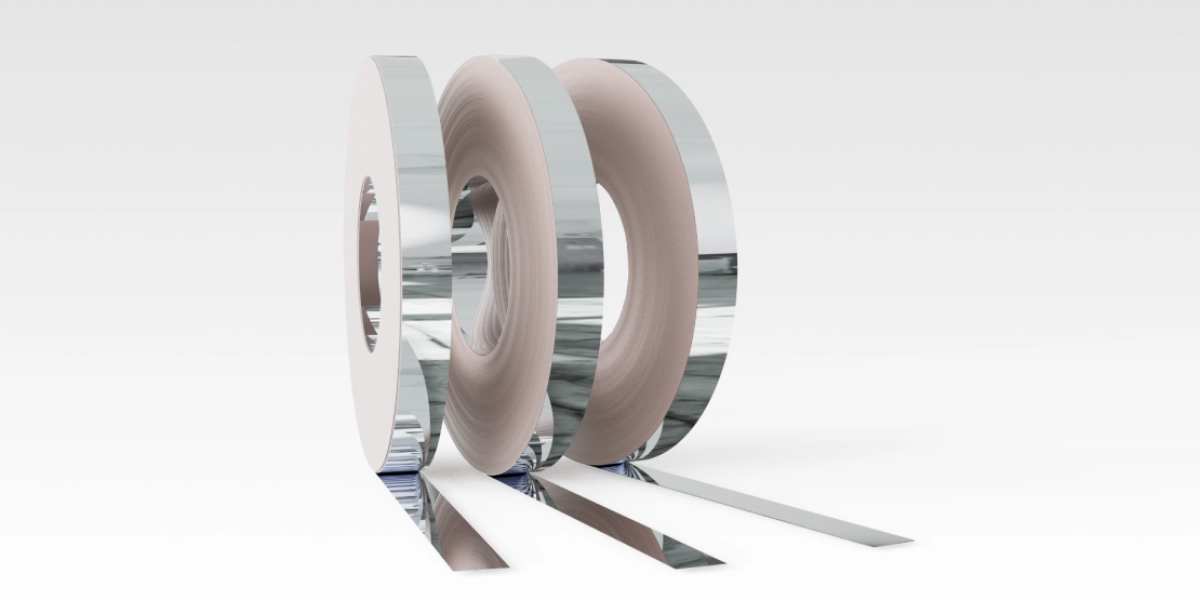

Hot dip tin plate stripes

Protective lined strips, sheets, and sheared strips

Bare strips