Die Casting

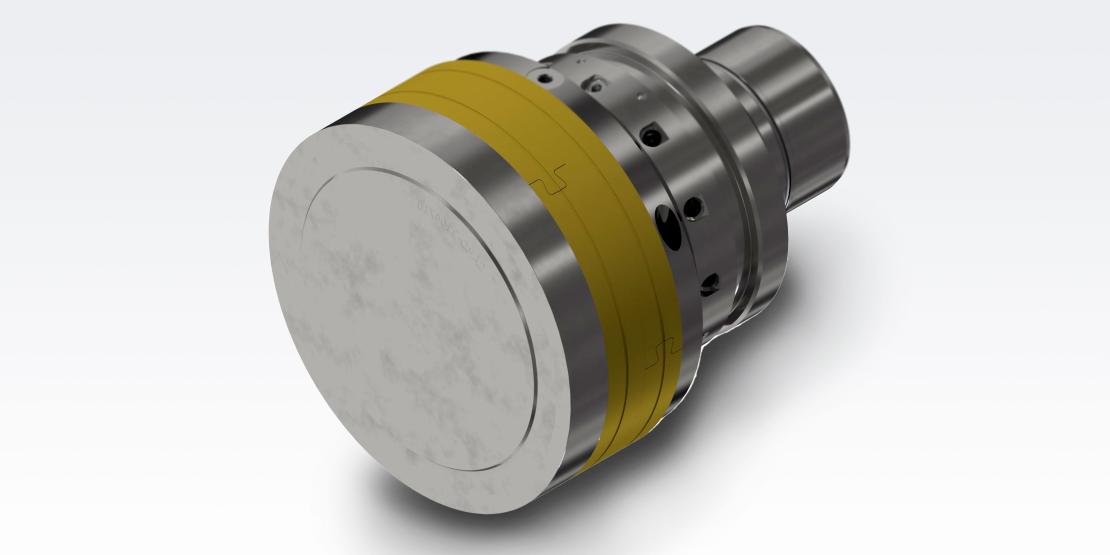

Entire system for high-pressure die casting

With high-pressure die casting, low-weight automotive components made of aluminum are manufactured. We supply best-in-class systems, developed in a partnership with the most renowned automotive manufacturers, testifying to the know-how and position of Wieland on the market.

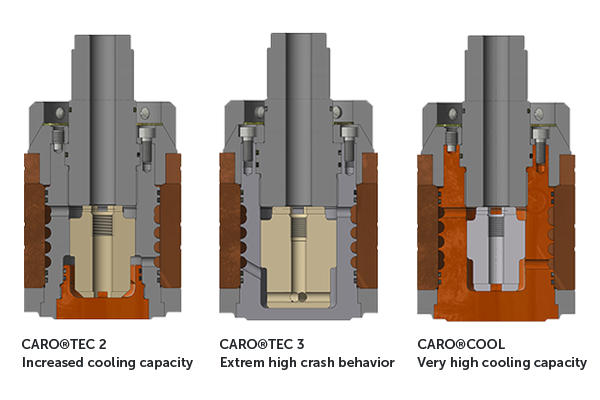

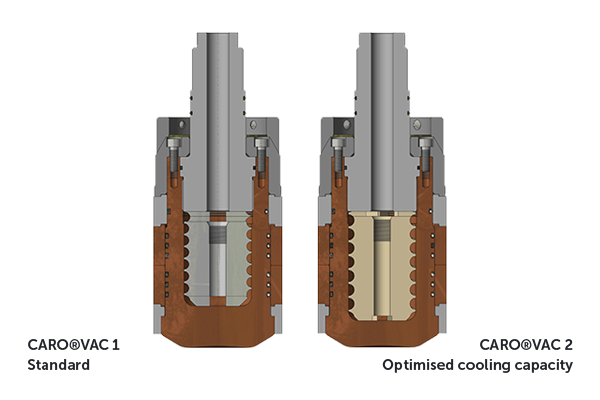

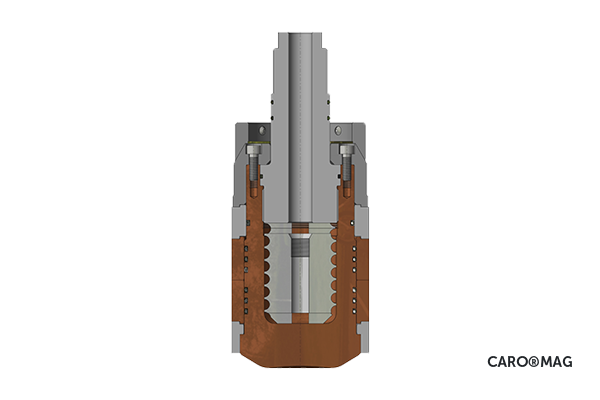

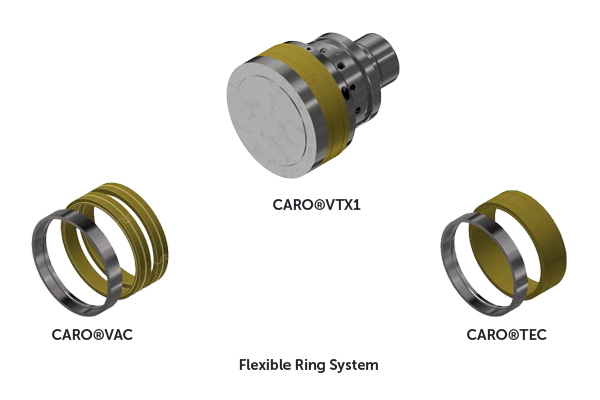

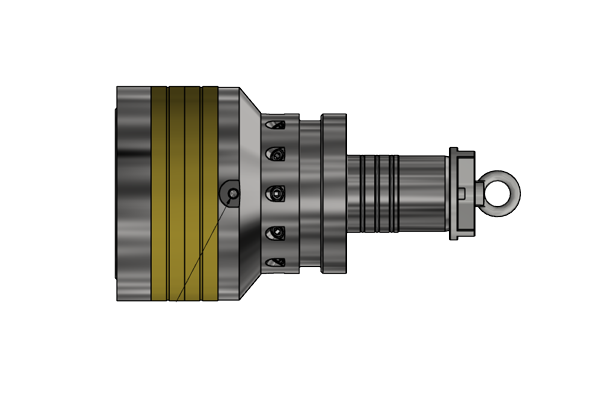

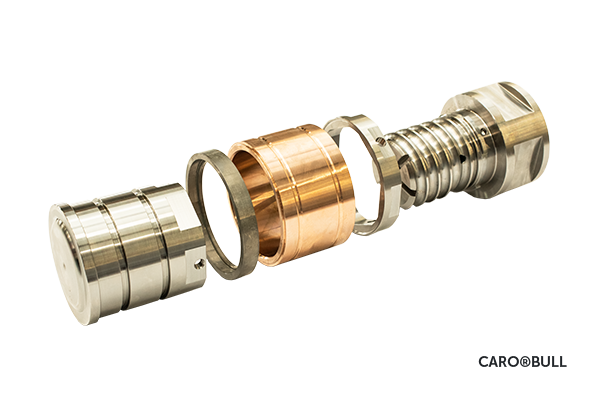

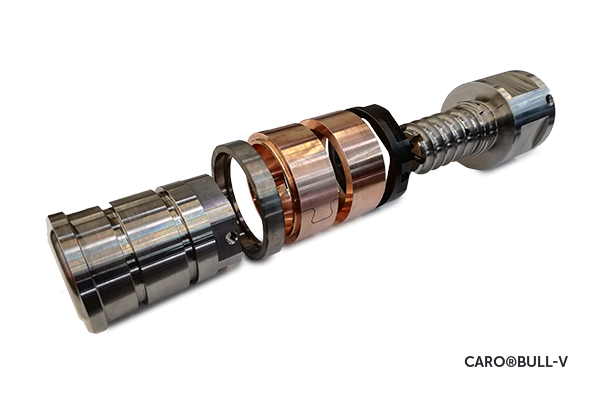

Our range of products

Our die casting at a glance.

Our complete product range

To show the product portfolio of a specific location, please select the company:

Already know your search term? Then go ahead and use our full text search. You will get a list of all relevant results.