Rods and sectional rods

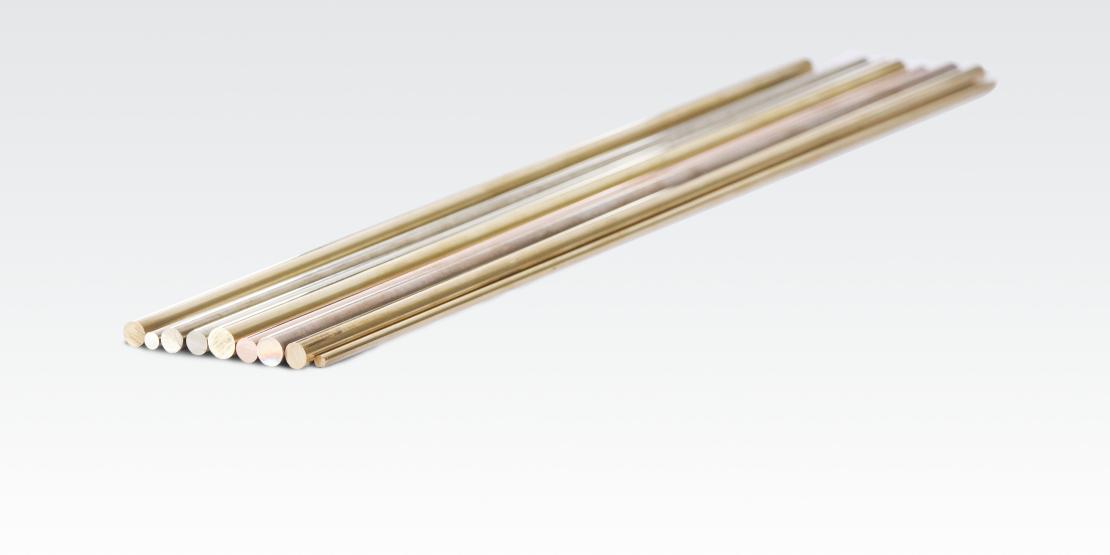

The right alloy, geometry, and strength – precise and efficient: simply Wieland. Rods and profiled rods are used in a wide range of applications, extending over forged sanitary fittings, lock cylinders and turned parts for machine construction. You can choose from a virtually unlimited number of sizes and geometries.

Special alloys tailored to your specific application are recommended by our Applications Engineering experts.

Our range of products

Our rods and sectional rods at a glance.

Our complete product range

To show the product portfolio of a specific location, please select the company:

Rods

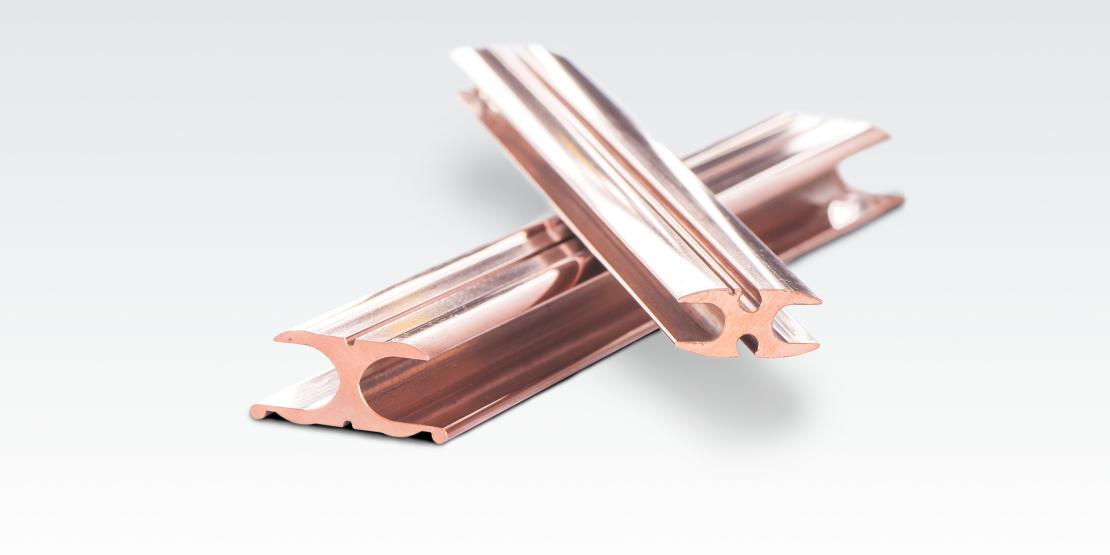

Sectional rod

Machining

WICONNEC®

ecoline®: Lead-free solutions

Precision continuous casting

Forging Stock

Materials

| Wieland | EN Designation | EN No. | ASTM UNS-No. |

|---|---|---|---|

| K08 | Cu-OFE | CW009A | C10100 |

| K12 | Cu-HCP | CW021A | C10300 |

| K18/K32 | Cu-ETP | CW004A | C11000 |

| K20/K21/K28 | Cu-DHP | CW024A | C12200 |

| K30 | Cu-OF | CW008A | C10200 |

| Wieland | EN Designation | EN No. | ASTM UNS-No. |

|---|---|---|---|

| Elmedur B2 | CuBe2 | CW101C | C17200 |

| Elmedur HA | CuCoNiBe | CW103C | ~C17500 |

| Elmedur HC | CuNi2Be | CW110C | C17510 |

| Elmedur NCS | CuNi2SiCr* | ~CW111C* | C18000 |

| Elmedur X | CuCrZr | CW106C | C18150 |

| Elmedur Z | CuZr | CW120C | C15000 |

| K41 | CuNi1Pb1P* | - | C19150 / C19160 |

| K44 | CuNi1Pb0.6P* | - | C19140 / C19150 |

| K52 | CuNi2Si | CW111C | C70260 |

| K53 | CuNi2SiS* | - | - |

| K54 | CuNi2SiCr* | - | C81540 |

| K60 | CuCr1Zr | CW106C | C18150 |

| K61 | CuCr1Zr | CW106C | C18200 |

| K65 | CuFe2P | CW107C | C19400 |

| K81 | CuSn0,15 | CW117C | C14415 |

| K96 | CuCo1Ni1Be | CW103C | - |

| KC1 | CuPb1P | CW113C | C18700 |

| KD1 | - | CW102C | - |

| KD3 | - | CW118C | - |

| eco KS2® | CuSP | CW114C | C14700 |

| Wieland | EN Designation | EN No. | ASTM UNS-No. | JIS-No. |

|---|---|---|---|---|

| Z11 | CuZn35Pb1 | CW600N | C34000 | |

| Z12 | CuZn35Pb2 | CW601N | C34200 / C34500 | |

| Z14 | CuZn37Pb2 | CW606N | C35300 | |

| Z21 | CuZn38Pb2 | CW608N | C3713 | |

| Z23 | CuZn36Pb3 | CW603N | C36000 | |

| Z29 | CuZn39Pb2 | CW612N | C37700 | |

| Z31/Z41/Z48 | CuZn40Pb2 | CW617N | C38000 | |

| Z32/Z33 | CuZn39Pb3 | CW614N | C38500 | |

| Z40 | CuZn43Pb2Al | CW624N | - | |

| Z43 | CuZn33Pb1AlSiAs | CW725R | - | |

| Z45/Z46 | CuZn36Pb2As | CW602N | C35330 |

| Wieland | EN Designation | EN No. | ASTM UNS-No. |

|---|---|---|---|

| EUCARO®10 | CuNi10Fe1,6Mn | CW 352H | C70600 |

| L10/L13/L15 | CuNi10Fe1Mn | CW352H | C70600 |

| L30 | CuNi30Mn1Fe | CW354H | C71500 |

| Wieland | EN Designation | EN No. | ASTM UNS-No. | JIS-No. |

|---|---|---|---|---|

| M10 | CuZn10 | CW501L | C22000 | C2200 |

| M15/M16/M17 | CuZn15 | CW502L | C23000 | |

| M20 | CuZn20 | CW503L | C24000 | C2400 |

| M30/M34 | CuZn30 | CW505L | C26000 | C2600 |

| M36 | CuZn36 | CW507L | C26800 / C27000 | C2700 |

| M37/M38 | CuZn37 | CW508L | C27200 | C2720 |

| eco M41® | CuZn38As | CW511L | C27453 | |

| eco M57® | CuZn42 | CW510L | - | |

| eco M58® | CuZn42 | CW510L | - |

| Wieland | EN Designation | EN No. | ASTM UNS-No. |

|---|---|---|---|

| S31 | CuZn31Si1 | CW708R | - |

| S35 | CuZn35Ni3Mn2AlPb | CW710R | - |

| S40 | CuZn37Mn3Al2PbSi | CW713R | C67420 |

| eco S34® | CuZn34Mn2SiAlNi* | - | C67340 |

| eco SW1® | CuZn21Si3P | CW724R | C69300 |

| eco SW5® | CuZn21Si3P | CW724R | C69300 |

| eco SZ2® | CuZn36Si1P | CW726R | C68370 |

| eco SZ3® | CuZn40SiP | - | - |

| eco SZ4® | CuZn42 | CW510L | C28500 |

| eco SZ5® | CuZn40 | CW509L | C27450 |

| ecobrass SW4 | CuZn21Si3P | CW724R | C69305 |

| Wieland | EN Designation | EN No. | ASTM UNS-No. |

|---|---|---|---|

| B06 | CuSn6 | CW452K | C51900 |

| B09/B10 | CuSn8 | CW453K | C52100 |

| B12/B21 | CuSn8P/CuSn8 | CW459K/CW453K | C52100 |

| B44/B45 | CuSn4Pb4Zn4 | CW456K | C54400 |

| BV9 | CuSn6 | CW452K | C51900 |

| eco BS4® | CuSn5NiPS* | - | - |

| Wieland | EN Designation | EN No. | ASTM UNS-No. |

|---|---|---|---|

| U33 | CuAl10Ni5Fe4 | CW307G | C63000 |

| U35 | CuAl10Ni5Fe4 | CW307G | C63020 |

| U36 | CuAl11Fe6Ni6 | CW308G | - |

| U39 | Cu Al10Fe3Mn2 | CW306G | - |

| Wieland | EN Designation | EN No. | ASTM UNS-No. | JIS-No. |

|---|---|---|---|---|

| N18 | CuNi18Zn20 | CW409J | C76400 | C7521 |

| N22 | CuNi12Zn24 | CW403J | C75700 | |

| N29 | CuNi18Zn20 | CW409J | - | |

| N31 | CuNi7Zn39Pb3Mn2 | CW400J | - | |

| N32 | CuNi12Zn30Pb1 | CW406J | - | |

| N37 | CuNi18Zn19Pb1 | CW408J | - | |

| N48 | CuNi12Zn38Mn5Pb2 | CW407J | - | |

| eco N59® | CuNi9Zn41FeMn* | - | - |

| Wieland | EN Designation | EN No. | ASTM UNS-No. |

|---|---|---|---|

| A01 | AlMgSiBi | AW-6026 | - |

| A02 | AlCu6BiPb | AW-2011 | - |

| A03 | AlCu4MgSi(A) | AW-2017A | - |

| A07 | AlZn5,5MgCu | AW-7075 | - |

| A11 | AlSi1Sn1MgBi | AW-6023 | - |

| A12 | AlMgSiPb | AW-6012 | - |

| A13 | AlMg3 | AW-5754 | - |

| A14 | AlMg4,5Mn0,7 | AW-5083 | - |

| A22 | AlMgSi | AW-6060 | - |

| A32 | AlSi1MgMn | AW-6082 | - |

| AlMg1SiCu | - | EN AW-6061 | - |

| AlSi1MnMgBi | - | EN AW-6026 | - |

| Anticorodal-112 | - | EN AW-6082 | - |

| Decoltal-500 | - | EN AW-2011 | - |

| Perunal-215 | - | EN AW-7075 | - |

| Wieland | EN Designation | EN No. | ASTM UNS-No. |

|---|---|---|---|

| PTX | ≈11SMnPb37(+Bi+Te/Se) | ≈1.0737 | ≈G12144 |

| PX | ≈11SMnPb37 | ≈1.0737 | ≈G12144 |

| Wieland | EN Designation | EN No. | ASTM UNS-No. |

|---|---|---|---|

| X6CrNiCuS18-9-2 (h8) | X6CrNiCuS18-9-2 (h8) | 1.4570 | AISI 303Cu |

| X6CrNiCuS18-9-2 (h9) | X6CrNiCuS18-9-2 (h9) | 1.4570 | AISI 303Cu |

| X8CrNiS18-9 (h11) | - | - | - |

| Wieland | EN Designation | EN No. | ASTM UNS-No. |

|---|---|---|---|

| X14CrMoS17 (h11) | - | - | - |

| X14CrMoS17 (h8) | X14CrMoS17 (h8) | 1.4104 | AISI 430F |

| X14CrMoS17 (h9) | X14CrMoS17 (h9) | 1.4104 | AISI 430F |

| X46CrS13 (h8) | X46CrS13 (h8) | 1.4035 | AISI 420C+S |

| Wieland | EN Designation | EN No. | ASTM UNS-No. |

|---|---|---|---|

| ETG 100 | ≈44SMn28 | ≈1.0762 | ≈G11440 |

| ETG 88 | ≈44SMn28 | ≈1.0762 | ≈G11440 |

| Wieland | EN Designation | EN No. | ASTM UNS-No. |

|---|---|---|---|

| High Density (HD) | - | - | - |

| Molybdän (Mo) | - | - | - |

| Molybdän-Lanthan (ML) | - | - | - |

| Niob (Nb) | - | - | - |

| Rhenium (Re) | - | - | - |

| Tantal (Ta) | - | - | - |

| Titan (Ti) | - | - | - |

| Titan-Zirkon-Molybdän (TZM) | - | - | - |

| Wolfram (W) | - | - | - |

| Wolfram-Kupfer (TUCO) | - | - | - |

| Wolfram-Rhenium | - | - | - |

| Zirkonium (Zr) | - | - | - |

Materials

| Wieland | EN Designation | EN No. | ASTM UNS-No. |

|---|---|---|---|

| K12 | Cu-HCP | CW021A | C10300 |

| K16 | Cu-ETP1 | CW003A | - |

| K18/K32 | Cu-ETP | CW004A | C11000 |

| K20/K21/K28 | Cu-DHP | CW024A | C12200 |

| K30 | Cu-OF | CW008A | C10200 |

| KA1 | CuAg0,10P | CW016A | - |

| Wieland | EN Designation | EN No. | ASTM UNS-No. |

|---|---|---|---|

| Elmedur NCS | CuNi2SiCr* | ~CW111C* | C18000 |

| Elmedur X | CuCrZr | CW106C | C18150 |

| Wieland | EN Designation | EN No. | ASTM UNS-No. |

|---|---|---|---|

| Z31/Z41/Z48 | CuZn40Pb2 | CW617N | C38000 |

| Z32/Z33 | CuZn39Pb3 | CW614N | C38500 |

| Wieland | EN Designation | EN No. | ASTM UNS-No. |

|---|---|---|---|

| B09/B10 | CuSn8 | CW453K | C52100 |

| B12/B21 | CuSn8P/CuSn8 | CW459K/CW453K | C52100 |

| Wieland | EN Designation | EN No. | ASTM UNS-No. |

|---|---|---|---|

| U33 | CuAl10Ni5Fe4 | CW307G | C63000 |

| Wieland | EN Designation | EN No. | ASTM UNS-No. |

|---|---|---|---|

| N22 | CuNi12Zn24 | CW403J | C75700 |

| Wieland | EN Designation | EN No. | ASTM UNS-No. |

|---|---|---|---|

| A22 | AlMgSi | AW-6060 | - |

| Wieland | EN Designation | EN No. | ASTM UNS-No. |

|---|---|---|---|

| Elmedur B2 | CuBe2 | CW101C | C17200 |

| Elmedur HA | CuCoNiBe | CW103C | ~C17500 |

| Elmedur HC | CuNi2Be | CW110C | C17510 |

| Elmedur NCS | CuNi2SiCr* | ~CW111C* | C18000 |

| Elmedur X | CuCrZr | CW106C | C18150 |

| Elmedur Z | CuZr | CW120C | C15000 |

| Wieland | EN Designation | EN No. | ASTM UNS-No. |

|---|---|---|---|

| High Density (HD) | - | - | - |

| Molybdän (Mo) | - | - | - |

| Molybdän-Lanthan (ML) | - | - | - |

| Niob (Nb) | - | - | - |

| Rhenium (Re) | - | - | - |

| Tantal (Ta) | - | - | - |

| Titan (Ti) | - | - | - |

| Titan-Zirkon-Molybdän (TZM) | - | - | - |

| Wolfram (W) | - | - | - |

| Wolfram-Kupfer (TUCO) | - | - | - |

| Wolfram-Rhenium | - | - | - |

| Zirkonium (Zr) | - | - | - |

The closer the input stock approaches the end product, the higher the efficiency of downstream machining. The Wieland E5006 precision hexagon rod fulfils these expectations in a quite special way: It presents the precise outer contours of a workpiece. Unlike machined multiedge cross sections, drawn edged rods are characterised by extremely smooth, plane, and compacted surfaces. Moreover, they lend the workpiece a continuous grain structure of high impact toughness. Obvious material savings are yet another benefit.

Learn more

W5006 precision brass rods

Our W5000 round rods are our premium product for your high performance machining operations. We guarantee the minimum diameter variance in the one batch and a straightness of 0.55 mm/m up to a diameter of 80 millimetres. And best of all: tight alloying tolerances for consistent machining results. Fine, uniform lead distribution for top machinability. Low contamination levels and optimised phase distribution for long tool lives.

Learn more

W5000 precision brass rods

The Wieland WICONNEC brand offers a range of copper materials in the form of rods and wires that are ideal for machined sockets and pins for plug connectors. This material portfolio also offers brass materials in addition to specially developed copper alloys for complex turned plug connectors.

Materials

| Wieland | EN Designation | EN No. | ASTM UNS-No. |

|---|---|---|---|

| K41 | CuNi1Pb1P* | - | C19150 / C19160 |

| K44 | CuNi1Pb0.6P* | - | C19140 / C19150 |

| KC1 | CuPb1P | CW113C | C18700 |

| eco KS2® | CuSP | CW114C | C14700 |

| Wieland | EN Designation | EN No. | ASTM UNS-No. |

|---|---|---|---|

| K55 | CuNi3Si1Mg* | - | C70250 |

| Wieland | EN Designation | EN No. | ASTM UNS-No. | JIS-No. |

|---|---|---|---|---|

| Z10 | CuZn37Pb0,5 | CW604N | C33500 | |

| Z11 | CuZn35Pb1 | CW600N | C34000 | |

| Z12 | CuZn35Pb2 | CW601N | C34200 / C34500 | |

| Z14 | CuZn37Pb2 | CW606N | C35300 | |

| Z21 | CuZn38Pb2 | CW608N | C3713 | |

| Z23 | CuZn36Pb3 | CW603N | C36000 | |

| Z32/Z33 | CuZn39Pb3 | CW614N | C38500 |

| Wieland | EN Designation | EN No. | ASTM UNS-No. |

|---|---|---|---|

| eco S34® | CuZn34Mn2SiAlNi* | - | C67340 |

Learn more about

Wieland ecoline

From Europe’s largest copper alloy foundry in Vöhringen/Iller (Germany), we can offer you far in excess of a hundred different copper materials. These include not only a wide range of continuous castings like tubes and rods, but also shaped rods and sections of complex geometries. At the same time, our flexibility ensures the prompt realisation of your special custom wishes.

Materials

| Wieland | EN Designation | EN No. | ASTM UNS-No. |

|---|---|---|---|

| G05 | CuSn5Zn5Pb5-C-GC | CC491K | - |

| G07/G08 | CuSn7Zn4Pb7-C | CC493K | - |

| G10 | CuSn10-C | CC480K | - |

| G12/G13 | CuSn12-C | CC483K | - |

| G21 | CuSn10Pb10-C-GC | CC495K | - |

| G22 | CuSn7Pb15-C | CC496K | - |

| G91 | CuSn11Pb2-C-GC | CC482K | - |

| GA1 | CuSn11Pb2-C-GC | CC481K | - |

| GB1 | CuSn12Ni2-C | CC484K | - |

| GD1 | CuSn5Zn5Pb2-C-GC | CC499K | - |

| eco GS1® | CuSn4Zn2PS-C-GC* | - | - |

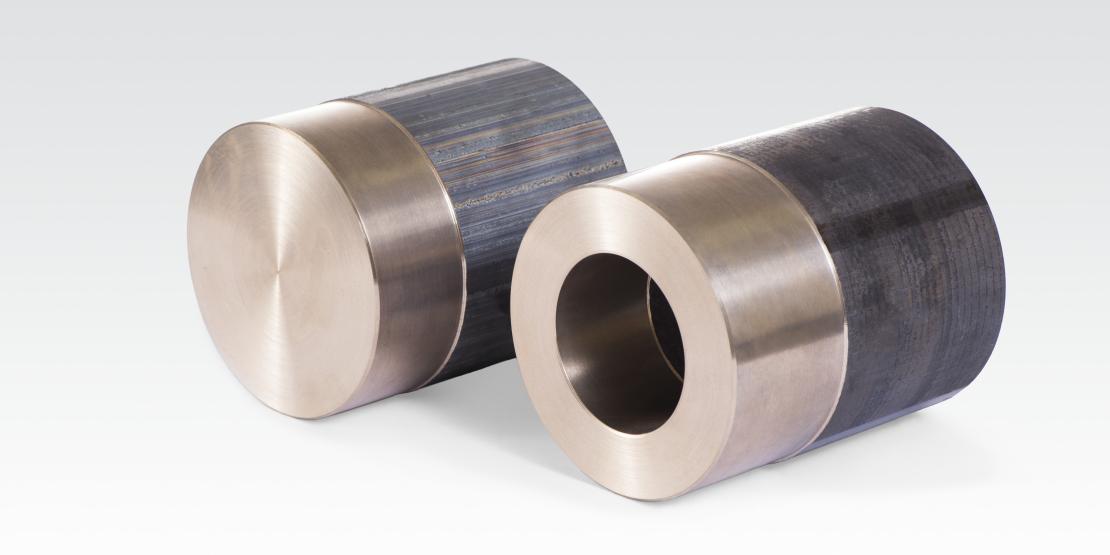

Wieland hot stamping rods

Good forging results can be obtained only when all links in the process chain have been matched to each other to the optimal effect. With Wieland hot stamping rods you are offered a forging stock which comprehensively fulfils these requirements. Your benefits: uniform dark surface for reproducible processing properties, tight diameter tolerances in the drawn size range, and hence precise configuration of the slug weight.

Materials

| Wieland | EN Designation | EN No. | ASTM UNS-No. |

|---|---|---|---|

| Elmedur B2 | CuBe2 | CW101C | C17200 |

| Elmedur HA | CuCoNiBe | CW103C | ~C17500 |

| Elmedur HC | CuNi2Be | CW110C | C17510 |

| Elmedur NCS | CuNi2SiCr* | ~CW111C* | C18000 |

| Elmedur X | CuCrZr | CW106C | C18150 |

| Wieland | EN Designation | EN No. | ASTM UNS-No. |

|---|---|---|---|

| Z31/Z41/Z48 | CuZn40Pb2 | CW617N | C38000 |

| Z32/Z33 | CuZn39Pb3 | CW614N | C38500 |

| Z45/Z46 | CuZn36Pb2As | CW602N | C35330 |

| Wieland | EN Designation | EN No. | ASTM UNS-No. |

|---|---|---|---|

| S35 | CuZn35Ni3Mn2AlPb | CW710R | - |

| S40 | CuZn37Mn3Al2PbSi | CW713R | C67420 |

| eco SW1® | CuZn21Si3P | CW724R | C69300 |

| ecobrass SW4 | CuZn21Si3P | CW724R | C69305 |

| Wieland | EN Designation | EN No. | ASTM UNS-No. |

|---|---|---|---|

| High Density (HD) | - | - | - |

| Molybdän (Mo) | - | - | - |

| Molybdän-Lanthan (ML) | - | - | - |

| Niob (Nb) | - | - | - |

| Rhenium (Re) | - | - | - |

| Tantal (Ta) | - | - | - |

| Titan (Ti) | - | - | - |

| Titan-Zirkon-Molybdän (TZM) | - | - | - |

| Wolfram (W) | - | - | - |

| Wolfram-Kupfer (TUCO) | - | - | - |

| Wolfram-Rhenium | - | - | - |

| Zirkonium (Zr) | - | - | - |

Contact person

Get in touch - Our experts for rods and sectional rods

![]() Fabio Schleicher

Fabio Schleicher

Sales Director Machining Brass & Specialties

Wieland-Werke AG

Send email

Related topics

This might be of interest to you

Already know your search term? Then go ahead and use our full text search. You will get a list of all relevant results.