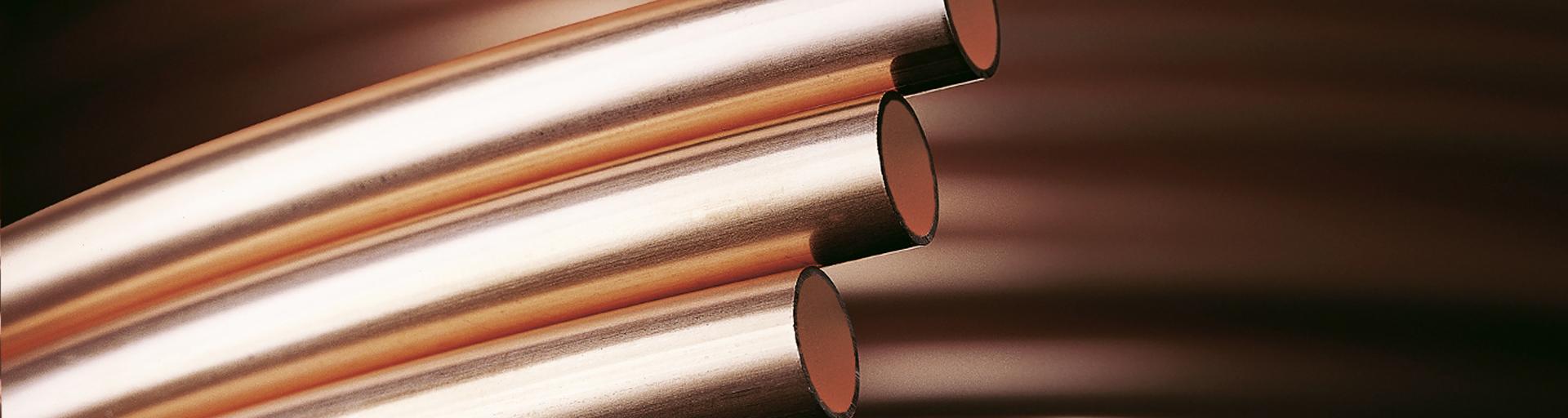

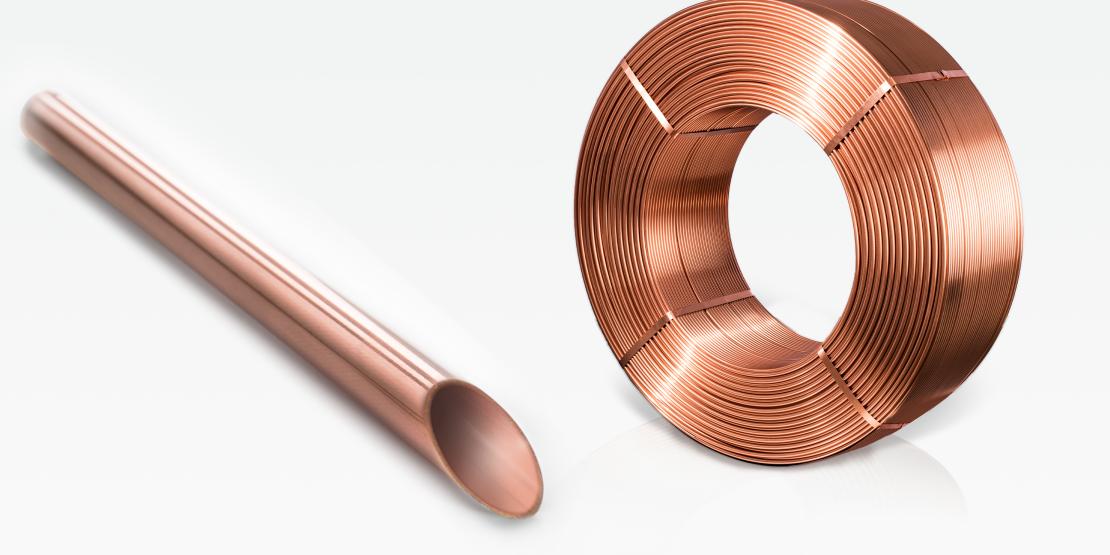

Smooth and innergrooved tubes

Wieland manufactures tubes tailored to customer requirements and the highest quality standards according to individual demands for a wide range of applications.

We burn for your individual requirements. Complex process sequences, continuously changing requirements and international competition pose ever new challenges for your company. With our customizing services we are able to master them together. This includes customer-specific services that allow you to break new ground, such as special qualities in strength and hardness, customer-specific product developments in form and function, as well as individual logistics solutions.

Our range of products

Our smooth and innergrooved tubes at a glance.

Wieland Metalix

This is our Wieland Metalix product portfolio.

Contact person

Get in touch - Our experts for smooth and innergrooved tubes

![]() Barbara Cataldo-Kühne

Barbara Cataldo-Kühne

Sales Inside Service

Wieland Metalix

+41 32 617 39 44

Send email

Already know your search term? Then go ahead and use our full text search. You will get a list of all relevant results.