Slide Bearings

Whether in high-performance combustion engines, modern axle and brake systems, gearboxes, differentials, or hydraulic pumps. Wieland slide bearings ensure smooth operation worldwide. They also prove their reliability in oscillating applications such as booms or gripper systems in construction and agricultural machinery. With more than 150 active alloys, Wieland offers a unique materials portfolio that provides solutions for a variety of requirements.

Wide range of solutions

Wieland offers a comprehensive spectrum of slide bearing solutions:

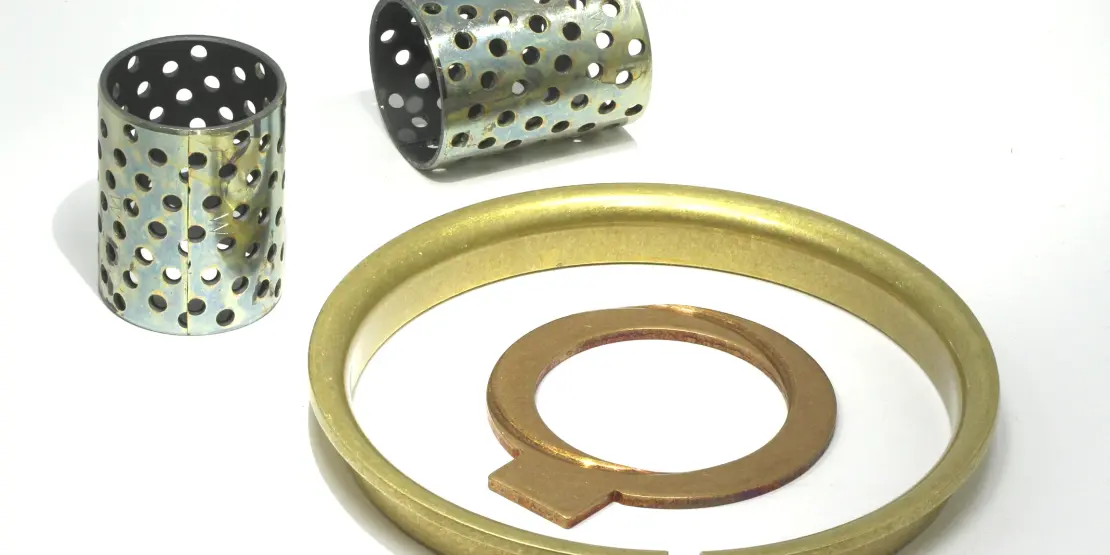

- Slide bearing bushes and thrust washers

Manufactured from Wieland strip, tube, or rod, available in nearly all dimensions. Whether with a smooth running surface, grooves, lubrication pockets, or special reservoirs; every version is manufactured to order and ready for installation. - Special parts and assemblies

Milled and turned parts, nuts, or threaded inserts made from copper alloys, individually combined and produced according to customer specifications. - Slide shoes and high-performance alloys

Our slide shoes are high-precision sliding elements that can be used reliably even under high dynamic loads, for example in axial piston pumps, engine construction, and demanding industrial applications. - High-performance coatings (AFC & HPC)

With PFAS-free sliding and polymer coatings, Wieland sets new industry standards. They reduce friction, extend service life, enable energy savings, and already comply with upcoming EU regulations.

Your benefits at a glance

- Low-maintenance to maintenance-free operation

- Cost savings through the elimination of complex lubrication systems

- No contamination from oil or grease

- Seawater- and corrosion-resistant

- Temperature-resistant and capable of withstanding dynamic loads

- Flexible designs according to drawings and batch sizes

Fields of application

Our slide bearings are used in:

- Automotive industry (pistons, connecting rods, brake systems, gearboxes)

- General machinery and plant engineering

- Hydraulic and pump systems

- Cranes, construction, and agricultural machinery

- Rolling mills and steelworks

- Locks, weir systems, and industrial furnace construction

- Food processing and packaging machinery

A leading manufacturer with global presence

As one of the leading suppliers of slide bearings and copper alloys, Wieland combines decades of materials expertise with state-of-the-art manufacturing technologies. Our made-to-order production offers maximum flexibility, from prototypes to series production. With sites in Europe, North America, and Asia, we stand for customer proximity, quality, and innovation worldwide.

Working with the best

Wieland collaborates closely with leading industrial companies to develop tailor-made solutions. This interplay of expertise, innovation, and customer focus makes us a reliable partner for slide bearings that meet the highest standards of precision, efficiency, and sustainability.

Rely on Wieland to set your projects in motion with innovative slide bearings.

Our range of products

Our slide bearings at a glance.

Our complete product range

To show the product portfolio of a specific location, please select the company:

Contact person

Get in touch - Our experts for slide bearings

![]() Volker Voggeser

Volker Voggeser

Vice President I BU Engineered Products

Wieland-Werke AG

+49 731 944-2135

Send email

Already know your search term? Then go ahead and use our full text search. You will get a list of all relevant results.