Wieland Kupral Kft.

- Cutting service (bandsaw and circular saw machines)

- Short delivery times

Organization

1037 Budapest

Hungary (UTC+1)

7:30 am - 3:30 pm

Friday

7:30 am - 1:30 pm

7:30 am - 3:30 pm

Friday

7:30 am - 1:30 pm

Metal Information

Current metal prices

Products

Our products at a glance

Product categories

Headline

Back to product overviewCaroTec plunger tip system

CaroVac plunger tip system

CaroMag magnesium plunger tip system

CaroLub lubrication devices

CaroShotsleeve system

CaroRod plunger rod system

CaroBull & CaroBull-V plunger tip system

Fittings

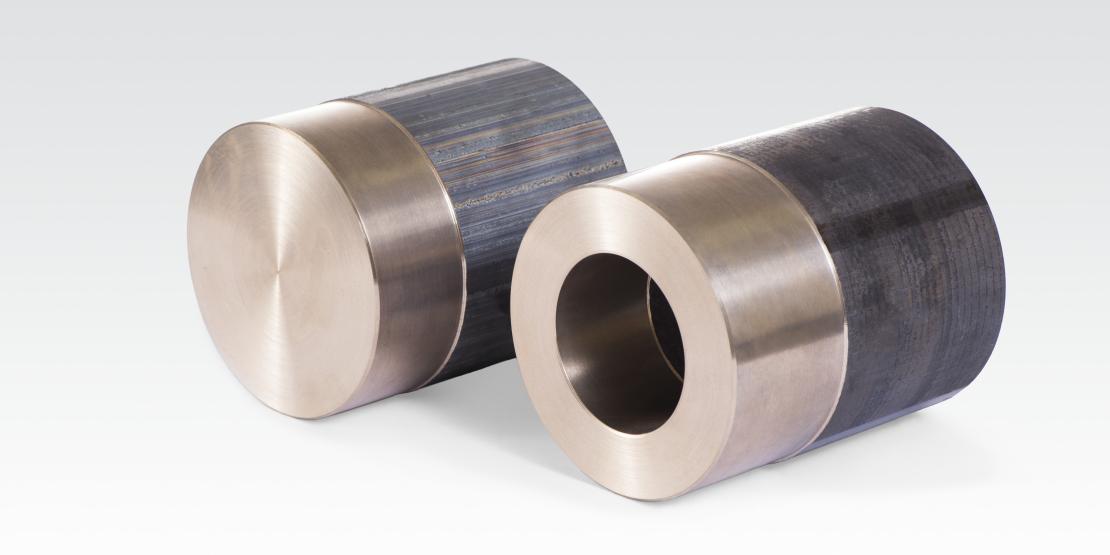

Finished parts

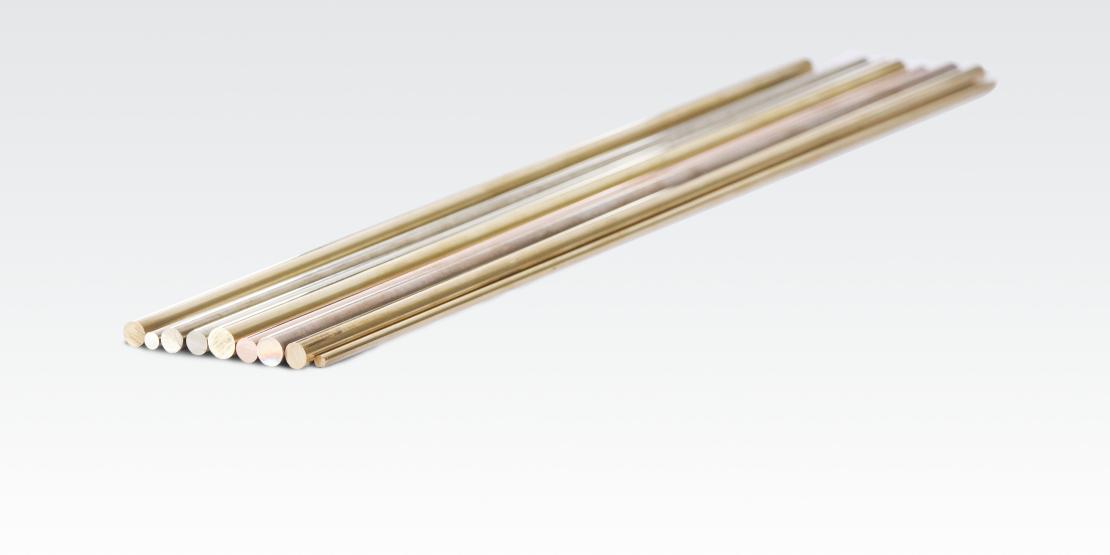

Rods

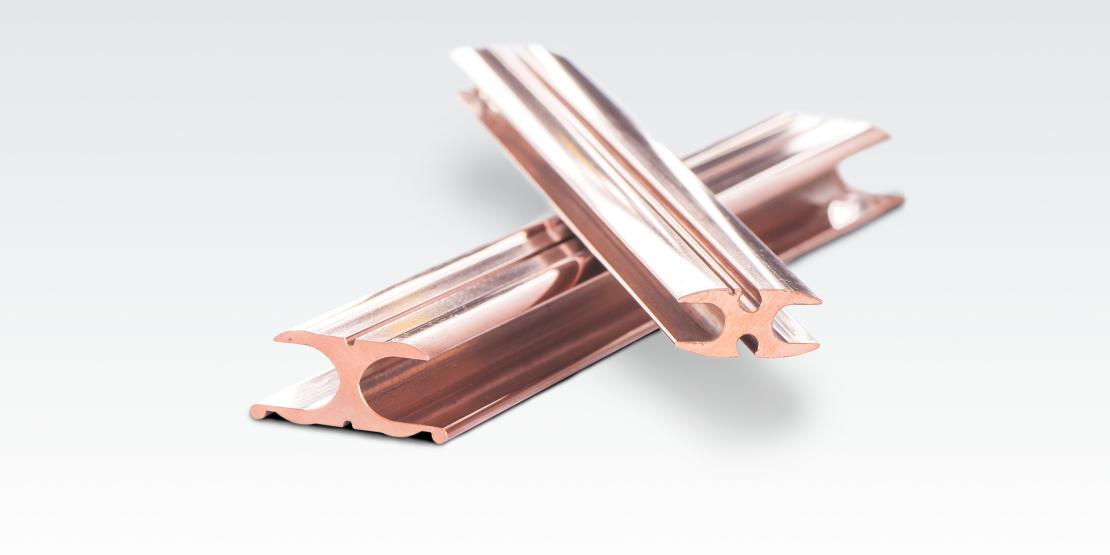

Sectional rod

WICONNEC®

ecoline®: Lead-free solutions

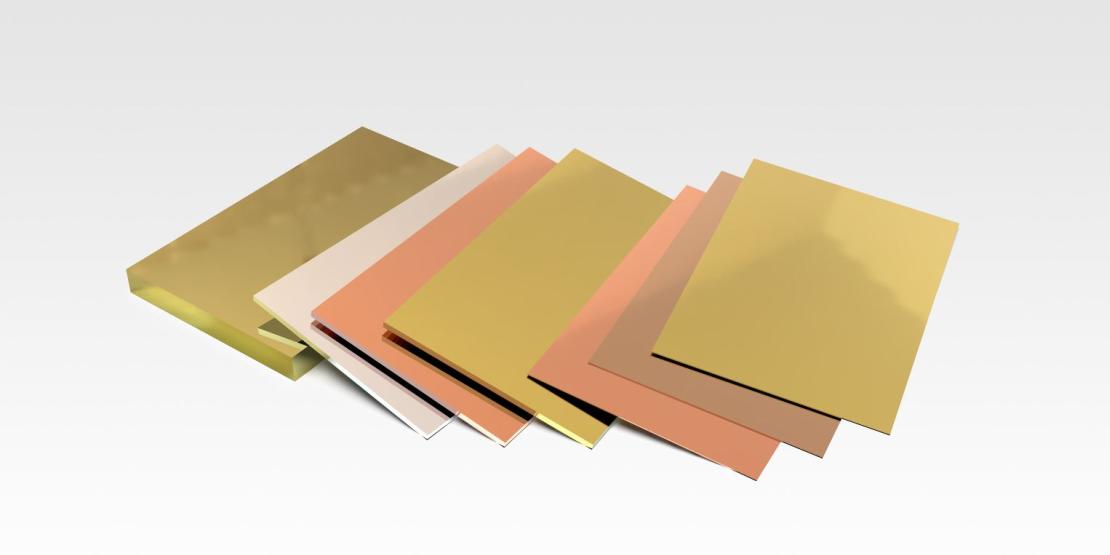

Precision continuous casting

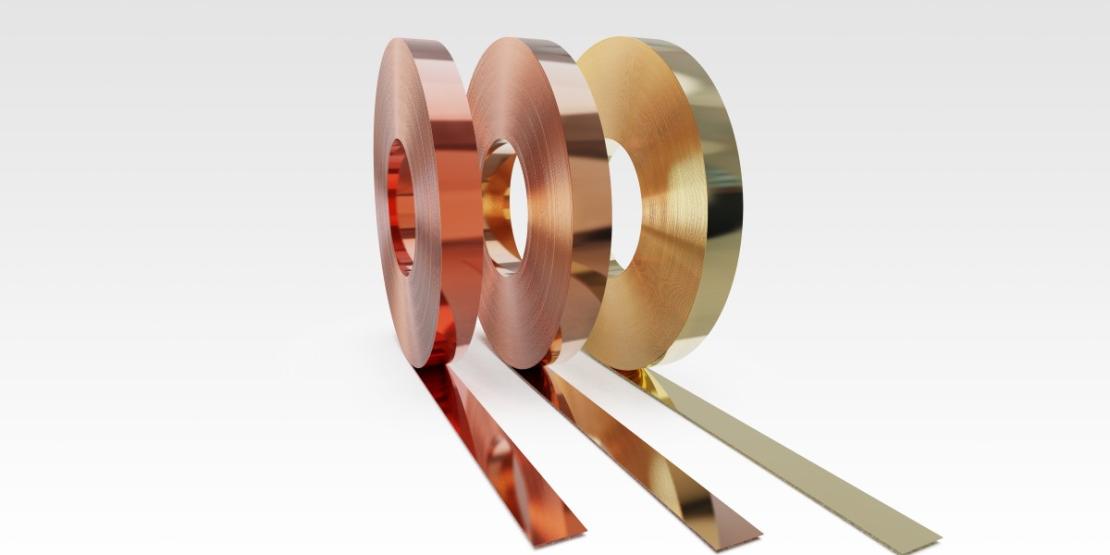

Strip

Sheets and Plates

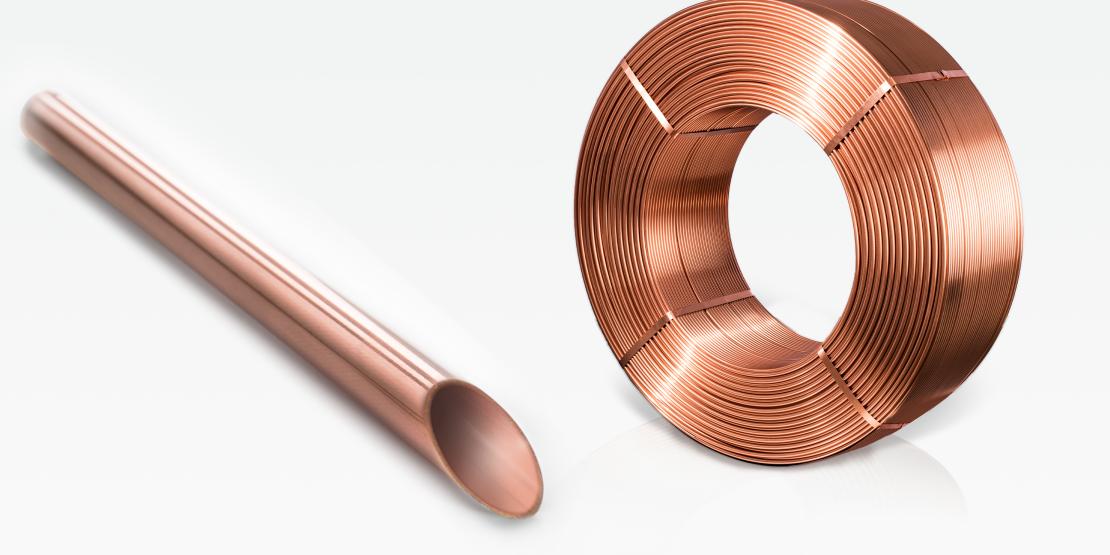

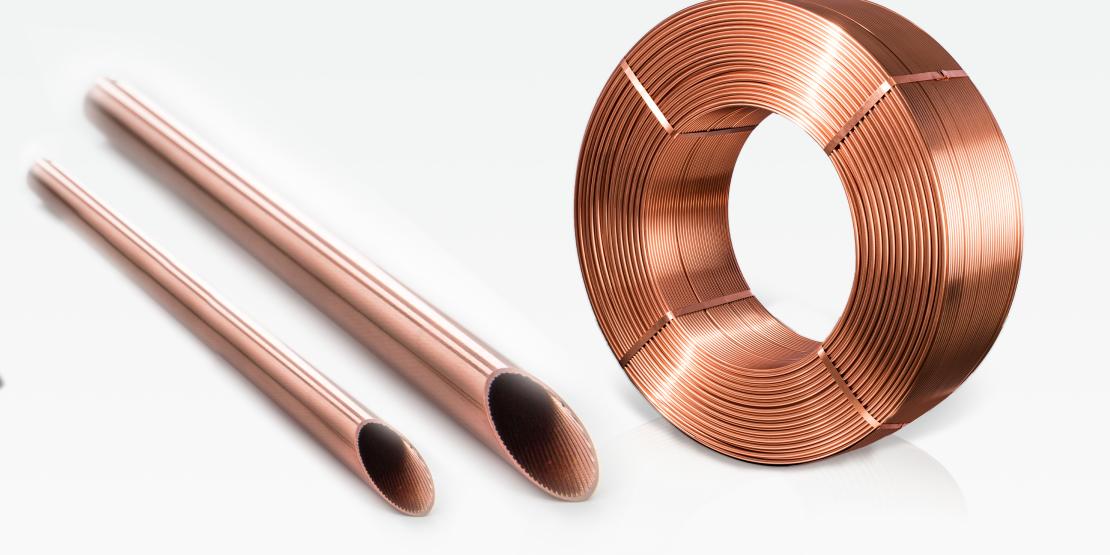

Smooth industrial tubes

Innergrooved industrial tubes

Plumbing tubes

Refrigeration and medical gas tubes

Tubes

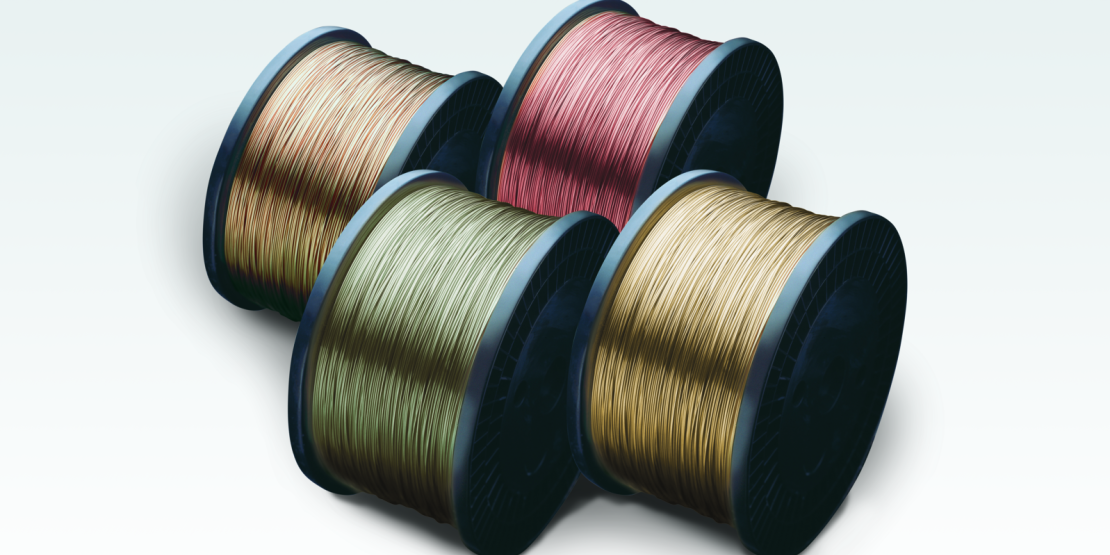

Wire

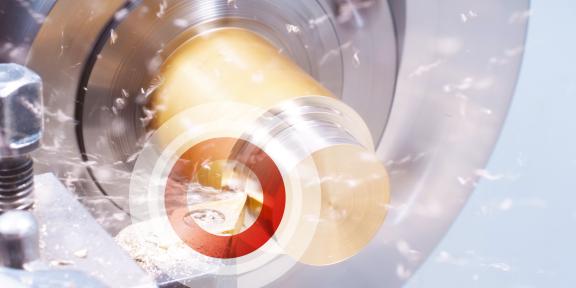

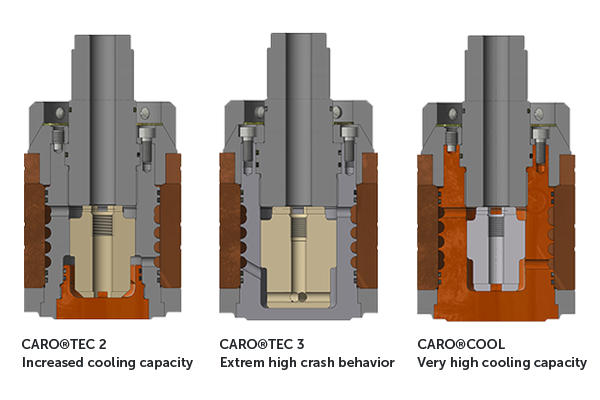

Optimizes your standard pressure die casting on conventional die casting machines

- Low wear plunger tip concept

- Very long service lifetime

- Selectable cooling capacity to optimize cycle times

Advantages

- Much longer lifetime compared to conventional plunger tips

- Body, clamping nut, threaded connection can be used several times

- Wear parts can be reworked to a smaller diameter

- With environmentally friendly beryllium and cobalt-free slide bushings

- Optimized tempering by forced cooling

- The modular construction system ensures flexibility even for casting intermediate sizes

- Reduced set-up costs and downtime due to longer service life of the plunger tips

Services

- Service center for plunger tip reworking and assembling

- Advisory service, process development and designing

- Comprehensive stock

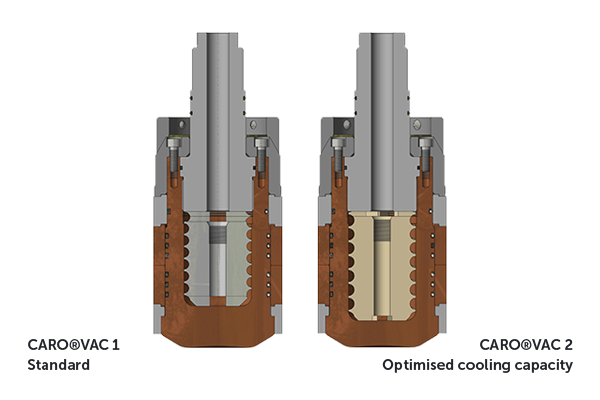

Optimizes vacuum die casting on HPDC

- Developed for structural and vacular die casting

- Low wear plunger tip concept for shot sleeves

- Very long service life

Advantages

- Highest evacuation level without additional sealing of shotsleeve or plunger rod

- No system-related maintenance or downtimes

- Applicable on vacuum and conventional DCM (mould sealing recommended)

- Compatible with any shotsleeve

- Closed pressure ring concept

- Only copper parts are in contact with shotsleeve

Services

- Service center for plunger tip reworking and assembling

- Advisory service, process development and designing

- Comprehensive stock

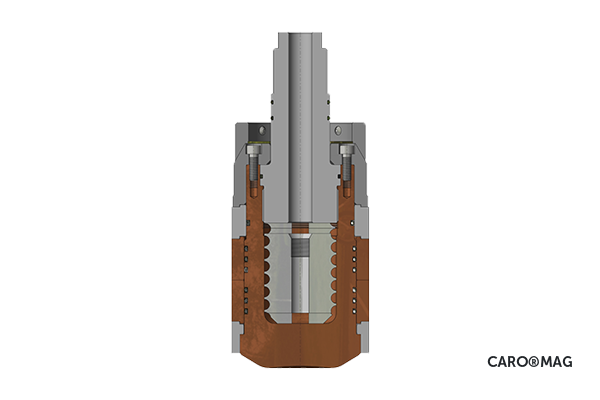

Optimizes magnesium die casting on vacuum or conventional HPDC

- Developed for magnesium and structural casting

- Plunger-tip concept for the protection of the shot sleeves

- Extremely high lifetime

Advantages

- Highest evacuation grades without additional sealing of shotsleeve or plunger rod

- No system-related maintenance times or lifetime

- Applicable on vacuum and conventional DCM

- Compatible with any shotsleeve

Services

- Service center for plunger tip reworking and assembling

- Advisory service, process development and designing

- Comprehensive stock

Efficient minimal quantity lubrication by plunger rod.

- The minimal quantity lubrication is applied through lubrication ring on plunger rod

- Depending on the required lubricant (viscosity) our devices can be equipped with the appropriate components

- A wide range of lubricants from various manufacturers can be applied

CARO®LUB 2.1

- Developed for structural casting

- Improved casting quality

- Significantly lower emissions and pollution

- Optionally with remote maintenance

- For minimal quantity lubrication with low-viscosity lubricants

CARO®LUB 3.1

- Developed for structural casting

- Improved casting quality

- Significantly lower emissions and pollution

- Possibility of remote maintenance

- For minimum quantity lubrication with highly viscosity lubricants

- Individually adjustable lubricant distribution

- Exactly adjustable lubrication quantities in ml

CARO®LUB 4.0

- Developed for structural casting and industry 4.0

- For highly viscous lubricants used for minimal quantity lubrication

- Improved casting quality

- Significantly lower emissions and pollution

- Individually adjustable lubricant distribution

- Exactly adjustable lubricant quantities in ml

- Application of state-of-the-art and high-quality components from Siemens

Made of high-performance alloys for longer lifetime.

- Multiple lifetime extension of shotsleeve

- Simple assembling and dismantling without mould changing

Product brochure CaroShotsleeve

CaroShotsleeve

- Lifetime extension due to sleeves and thermo regulation

- Specifically for low iron aluminum alloys

- Reduces pre-damage risk of hot aluminium

- Optional with quick change sleeve

Carosleeve

- Different alloys and treatments available

- Specifically for low iron aluminum alloys

- Very good wear resistance in filling-area (Hot Spot)

- Lifetime extension of shotsleeve

- Fast & easy assembly and dismantling at DCM

Services

- Advisory service, process development and designing

- Provider for die-casting technology e.g. plunger tips, plunger rods, quick-coupling systems, vacuum-casting for structural parts and magnesium parts

- Service center for reworking of shot sleeve and assembling

Custom-fit in high-quality rods for any machine type, optional with quick coupling system

- Manufacture of plunger rods for all machine types

- Change from plunger rods with adapter to CaroTec and CaroVac system

- Optional with quick coupling unit

CaroRod with integrated lubrication in combination with CaroLub spraying devices enable:

- Improved casting quality

- Minimal lubricant consumption

- Significantly lower emissions

Product brochure CaroTec & CaroRod plunger rod system

Product brochure CaroVac & CaroRod plunger rod system

Guide elements on CaroRod

- For easy change of plunger tip and easy adjustment

- For safety when overriding the chamber

- Load relief of plunger tips and coupling

Services

- Service center for reconstruction and repair

- Advisory service, process development and designing

- System supplier in die-casting technology

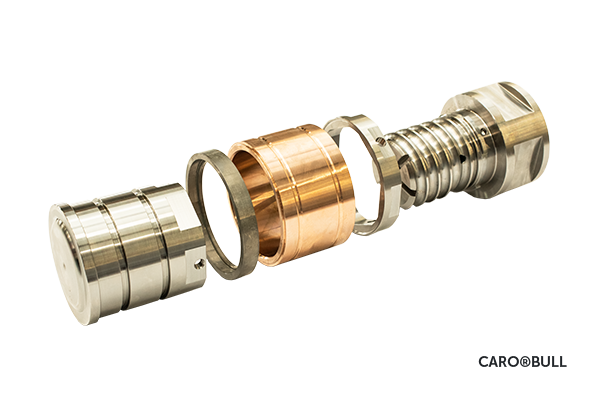

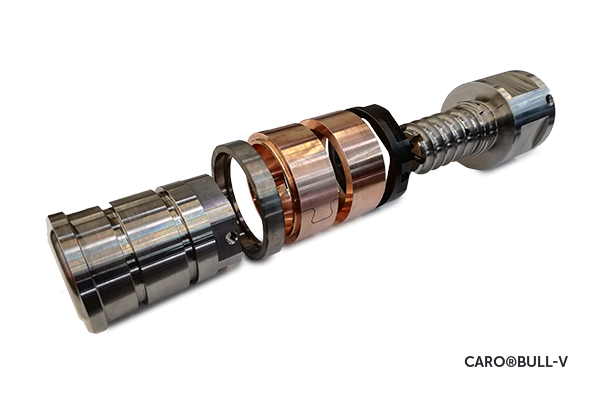

Optimizes the standard die casting

- Designed for flexible use on any DCM

- Suitable for standard and vacuum products (flexible ring system)

Advantages

- Easy changeover from solid tip to system plunger tip system

- Vacuum: Flexible change of glide bushing to circlips for vacuum application

- Can be fitted on existing plunger rods

- Proven ring system

- Closed pressure ring (prevents honing, no contact to shotsleeve)

- Soft Slide bushing in contact to shotsleeve

- Ring (spare parts) change in a few simple steps directly at the DGM

- Plunger tip change in a few steps due to bayonet lock (patented)

Product brochure CaroBull & CaroBull-V

Services

- Service center for plunger tip reworking and assembling

- Advisory service, process development and designing

- Comprehensive stock

Solder fitting

For connoisseurs of the plumbing and heating trade, the Conex | Bänninger >B< is a trademark that has stood for safety, quality and innovative products since 1909.

Fittings made of copper from Conex | Bänniger of the 5000 series: this material is oxygen-free and contains a copper mass fraction of at least 99.90%. It has excellent soft and hard solderability.

Gunmetal fittings from Conex | Bänniger of the 4000 and 3000 series: the gunmetal alloy of the cast fittings fully complies with the requirements of the new EN 1982 and can therefore be used for drinking water in accordance with ÖNORM

B 5014-3. The alloy offers the highest possible protection and has good soft and hard solderability.

CONEX clamping ring connectors

CONEX clamping ring connectors belong to the group of metal-sealing smooth pipe connections and consist of a fitting body, clamping ring and union nut. The tubes to be connected are pushed through the pre-assembled connection into the fitting body as far as it will go and the union nut is tightened by hand. The union nuts are tightened with commercially available tools or with the CONEX wrench. In the process, the clamping ring deforms and forms the metallic sealing connection between the tube and the fitting.

>B< Press Fitting and >B< Press Gas Fitting

With the current >B< Press connection technology made of material copper and gunmetal, we offer another highly economical installation technology. >B< Press Fittings series P4000 and P5000 have been specially developed for the field of plumbing and heating installation and can also be used for many other applications. The >B< Press Fittings range includes over 300 different items in copper and gunmetal materials. The >B< Press Gas Fittings series PG4000 and PG5000 have the quality mark certificate no. G 2.692 for gas.

>B< Oyster

The high quality transition coupling >B< Oyster made of gunmetal allows a quick, clean and economical assembly of all screwed components with internal thread. Application in the fields of drinking water, rainwater, heating, oil-free compressed air and in industry. The cold and energy-independent connection technology is particularly suitable for installation in areas at risk of fire. >B<-Oysters are detachable and reusable.

Do you need finished parts according to drawings? Here, too, we are your competent supplier.

We offer you for example:

- electrodes and other accessories for resistance welding technology

- input material for die-cast pistons and finished pistons

- semi-finished products made of highly conductive copper-based materials for tool and mould construction

- parts made of refractory metals

Components from Elmedur

Our Elmedur materials are particularly versatile. We produce parts from them according to drawings - and of course also individual parts. All according to your wishes and requirements.

Electrodes

No matter which electrodes you need: Among our large selection of standard electrodes you will find the right one for your purposes. We manufacture electrodes from hardenable copper materials, which are very hard and at the same time highly conductive. They are ideal for applications in which high electrical currents are transmitted under high mechanical loads.

Components made of high-melting metals

From our refractory metals molybdenum, TZM, tungsten and tantalum we manufacture parts according to drawings as well as individual parts. As the metals are very easy to process, they are ideal for a wide range of applications.

Materials

| Wieland | EN Designation | EN No. | ASTM UNS-No. |

|---|---|---|---|

| K18/K32 | Cu-ETP | CW004A | C11000 |

| Wieland | EN Designation | EN No. | ASTM UNS-No. |

|---|---|---|---|

| K54 | CuNi2SiCr* | - | C81540 |

| K60 | CuCr1Zr | CW106C | C18150 |

| K96 | CuCo1Ni1Be | CW103C | - |

| Wieland | EN Designation | EN No. | ASTM UNS-No. | JIS-No. |

|---|---|---|---|---|

| Z21 | CuZn38Pb2 | CW608N | C3713 | |

| Z31/Z41/Z48 | CuZn40Pb2 | CW617N | C38000 | |

| Z32/Z33 | CuZn39Pb3 | CW614N | C38500 |

| Wieland | EN Designation | EN No. | ASTM UNS-No. | JIS-No. |

|---|---|---|---|---|

| M37/M38 | CuZn37 | CW508L | C27200 | C2720 |

| Wieland | EN Designation | EN No. | ASTM UNS-No. |

|---|---|---|---|

| S40 | CuZn37Mn3Al2PbSi | CW713R | C67420 |

| eco ST2 | CuZn35Sn1P | CW727R | - |

| eco ST3 | CuZn29Si1SnP | CW729R | - |

| eco ST4 | CuZn42 | CW510L | - |

| eco SW1® | CuZn21Si3P | CW724R | C69300 |

| eco SZ2® | CuZn36Si1P | CW726R | C68370 |

| eco SZ3® | CuZn40SiP | CW728R | - |

| eco SZ4® | CuZn42 | CW510L | C28500 |

| eco SZ5® | CuZn40 | CW509L | C27450 |

| Wieland | EN Designation | EN No. | ASTM UNS-No. |

|---|---|---|---|

| B09/B10 | CuSn8 | CW453K | C52100 |

| B12/B21 | CuSn8P/CuSn8 | CW459K/CW453K | C52100 |

| Wieland | EN Designation | EN No. | ASTM UNS-No. |

|---|---|---|---|

| U33 | CuAl10Ni5Fe4 | CW307G | C63000 |

| U39 | Cu Al10Fe3Mn2 | CW306G | - |

| Wieland | EN Designation | EN No. | ASTM UNS-No. |

|---|---|---|---|

| A22 | AlMgSi | AW-6060 | - |

| A32 | AlSi1MgMn | AW-6082 | - |

| Wieland | EN Designation | EN No. | ASTM UNS-No. |

|---|---|---|---|

| eco ST2 | CuZn35Sn1P | CW727R | - |

| eco ST3 | CuZn29Si1SnP | CW729R | - |

| eco ST4 | CuZn42 | CW510L | - |

| Wieland | EN Designation | EN No. | ASTM UNS-No. |

|---|---|---|---|

| B12/B21 | CuSn8P/CuSn8 | CW459K/CW453K | C52100 |

The Wieland WICONNEC brand offers a range of copper materials in the form of rods and wires that are ideal for machined sockets and pins for plug connectors. This material portfolio also offers brass materials in addition to specially developed copper alloys for complex turned plug connectors.

Learn more about

Wieland ecoline

From Europe’s largest copper alloy foundry in Vöhringen/Iller (Germany), we can offer you far in excess of a hundred different copper materials. These include not only a wide range of continuous castings like tubes and rods, but also shaped rods and sections of complex geometries. At the same time, our flexibility ensures the prompt realisation of your special custom wishes.

Materials

| Wieland | EN Designation | EN No. | ASTM UNS-No. | Dimensions |

|---|---|---|---|---|

| G05 | CuSn5Zn5Pb5-C-GC | CC491K | - | |

| G07/G08 | CuSn7Zn4Pb7-C | CC493K | - | |

| G10 | CuSn10-C | CC480K | - | |

| G12/G13 | CuSn12-C | CC483K | - | 10 – 354 mm |

| G12/G13 | CuSn12-C | CC483K | - | 10–354 mm |

| G12/G13 | CuSn12-C | CC483K | - | 22×22– 203×203 mm |

| G12/G13 | CuSn12-C | CC483K | - | 22 × 22 bis 203 × 203 mm |

| G12/G13 | CuSn12-C | CC483K | - | 22 × 12 bis 312 × 52 mm |

| G12/G13 | CuSn12-C | CC483K | - | 13 - 130 mm; on request |

| G12/G13 | CuSn12-C | CC483K | - |

| Wieland | EN Designation | EN No. | ASTM UNS-No. |

|---|---|---|---|

| K12 | Cu-HCP | CW021A | C10300 |

| K12 | Cu-HCP | CW021A | C10300 |

| K18 | Cu-ETP | CW004A | C11000 |

| K18 | Cu-ETP | CW004A | C11000 |

| Wieland | EN Designation | EN No. | ASTM UNS-No. | Dimensions | Temper |

|---|---|---|---|---|---|

| Z30 | CuZn39Pb2 | CW612N | C37700 | 670 × 1340 and 600 × 2000 format; thicknesses from 0.8 to 30 mm | hardened |

| Z30 | CuZn39Pb2 | CW612N | C37700 | 0.3 – 120 mm | R360/R490/R560 F36/F49/F59 |

| Z30 | CuZn39Pb2 | CW612N | C37700 |

| Wieland | EN Designation | EN No. | ASTM UNS-No. | JIS-No. | Dimensions | Temper |

|---|---|---|---|---|---|---|

| M38 | CuZn37 | CW508L | C27200 | C2720 | 0.2 –10 mm | R300/R350/R480/R550 F30/F37/F44/F54 |

| M38 | CuZn37 | CW508L | C27200 | C2720 |

| Wieland | EN Designation | EN No. | ASTM UNS-No. |

|---|---|---|---|

| U33 | CuAl10Ni5Fe4 | CW307G | C63000 |

Available materials

| Wieland | EN | EN-Nr. | UNS |

| K20 / K21 / K28 | Cu-DHP | CW024A | C12200 |

| L10 | CuNi10Fe1Mn | CW352H | C70600 |

| K65 | CuFe2P | CW107C | C19400 |

Materials

For a more sustainable future in construction.

With its 100 % share of recycled material, the cuprolife copper tube makes a sustainable difference, and thus makes a significant contribution to the advancement of building and construction as well as building services.

Every cuprolife tube from Wieland is manufactured in keeping with the mass balance approach – using a process with 100 % recycled copper. As the starting point when verifying cuprolife, TÜV SÜD tested the procedure for calculating the 100 % recycled content*.

The new standard in copper tubes: cuprolife®.

Thanks to cutting-edge manufacturing techniques, cuprolife tubes exceed even the highest requirements. Optimal efficiency and reliability are guaranteed along with an exceptional service life. cuprolife tubes are universally usable. cuprolife is permanently in stock and can be supplied in any size from 6 x 1 mm to 159 x 3 mm.

Fields of application

- Domestic hot and cold water supply

- Heating

- Gas

- Liquid gas

- Heating oil / biofuel oil B10

- Solar systems

- Rainwater

- Industrial compressed air

- Sprinkler systems

- Firefighting systems

Technical features

- 100 % recycled copper*

- Design according to EN 1057, quality assured

- Made of pure copper Cu-DHP

- With quality mark and DVGW certification: DV-7204AU2106 (6 to 159 mm outside diameter)

- Universal use in a range of finely differentiated dimensions

- Optimum availability and compatibility with a wide range of fittings

- Maximum operating temperature at 10 bar operating pressure: 250 °C (applies to dimensions up to DN 150)

- Fire resistance: EN 13501-1 – A1 (nonflammable)

- Dimensions according to DVGW GW 392 (6 to 159 mm) with closed tube ends

- For optimal drinking water hygiene

*Mass balance approach, based on ISO 14021, verified by TÜV SÜD.

Reliable for all areas of home installation

For many years, installers have been relying on SANCO branded copper tubes. The tubes are very reliable, suitable for all areas of domestic installation and have more than proven their worth in practice. Whether drinking water supply (hot and cold), heating systems, oil, gas and liquid gas supplies as well as thermal solar systems: Wieland SANCO tubes are always the right choice and, of course, covered by the relevant regulations.

Technical features

- Patented manufacturing process: SANCO tubes are significantly better than required by standards and regulations.

- Design according to EN 1057, quality assured

- Made of pure copper Cu-DHP

- With quality mark and DVGW certification:

DV-7204AU2106 (12 to 159 mm outside diameter). - Universal use in a range of finely differentiated dimensions

- Optimum availability and compatibility with a wide range of fittings

- Maximum operating temperature: 250 °C

- Fire resistance: EN 13501-1-A1 (non-flammable)

- Dimensions according to DVGW GW 392 (12 to 159 mm) with closed tube ends

- For optimal drinking water hygiene

- Wide range of certifications available, such as Kitemark, Afnor, KIWA, DVGW and many others

Fields of application

- Domestic hot and cold water supply

- Heating systems

- Gas and oil services for heating and cooking

- Solar systems

- Rainwater

- Industrial compressed air

- Sprinkler and Fire-fighting-systems

- Further applications in consultation with our technical advisory service

WICU

WICU tubes a have a mill-applied protective coating. They are therefore suitable for concealed installation under plaster or in environments with an aggressive atmosphere, and for installation outdoors, either above or below ground.

Technical features

- Design according to EN 1057, quality assured

- Made of pure copper Cu-DHP

- With quality mark and DVGW certification:

- DV-7204AU2106 (12 to 42 mm outside diameter).

- Protective coating conforms to EN 13349 and DIN 30672-1 class B

- Reduction of condensation

- Fire resistance: EN 13501-1-E

- Color of coating: light gray

- Temperature range up to 100 °C

Fields of application

- Domestic hot and cold water supply

- Heating systems

- Gas and oil services for heating and cooking

- Rainwater

- Industrial compressed air

- Further applications in consultation with our technical advisory service

WICU Flex

WICU Flex is a plumbing tube with a flexible coating for rapid installation. The coating consists of closed-cell PE foam covered by a structured protective film. WICU Flex is supplied in coils for rapid connection to manifolds etc. and for underfloor installations.

Technical properties

- Design according to EN 1057, quality assured

- Made of pure copper Cu-DHP

- With quality mark and DVGW certification:

DV-7204AU2106 (12 to 22 mm outside diameter) - CFC/FKW-free polyethylene foam (PE) with a

- PE structural foil

- Sound insulation: DIN 4109 - A1

- Thermal conductivity of the insulation layer according to DIN 52613:

= 0.040 W/mK at 40 °C - Fire resistance: N 13401-1-E

- Color of coating: white

- Temperature application range: up to 100 °C

Fields of application

- Connecting tubes

- Domestic hot and cold water supply

- Central heating systems

cuprotherm CTX

cuprotherm CTX tubes are copper tubes with a firmly adhering coating. Due to their structure, they are very easy to process and are characterized by a flexibility so far unknown for metal tubes. CTX tubes are a technically high-quality and at the same time economically interesing solution: They offer an attractive price per meter for copper tubes at stable conditions, and are therefore also convincing in terms of reliability in planning.

Technical features

- Flexible copper tube made of pure copper Cu-DHP

- Temper: soft R220 according to EN 1057 with firmly adhering coating made of PE-RT

- Fire behavior EN 13501-1, class E

- Color of the coating: white, similar to RAL 9010 (pure white)

- Temperature application range: up to 100 °C

Fields of application

- Heating

- Cooling

- Radiator connection

- Rainwater harvesting systems

- Ground collectors (water/glycol)

- Concrete core activation

cuprotherm.plus

cuprotherm is Europe's most frequently installed copper underfloor heating system, and for good reason. The outstandingly long service life of cuprotherm copper tubes will make you forget about surface heating for decades after it has been installed. Due to the highest thermal donductivity in technical materials, efficient use for this application is also good for the wallet in the long run.

The orange coating provides mechanical and chemical protection from the outside and allows the cuprotherm tube to expand unhindered in length when the temperature changes.

Technical properties

- Design according to EN 1057

- Fire resistance: EN 13501-1-E

- Building material class: DIN 4102 - A1

- With quality mark

- Diffusion rate: 0.00 mg/m²*d after 50 years

Fields of application

- Surface heating and cooling

- Wall heating

- Industrial surfaceheating

- Sports floor heating

cuprotherm.blank

cuprotherm is Europe's most frequently installed copper underfloor heating system, and that for good reasons. The oustandingly long service life of cuprotherm copper tubes will make you forget about surface heating for decades after it has been installed. Due to the highest thermal conductivity in technical materials, efficient use for this application is also good for the wallet in the long run.

The bare copper tube also withstands high temperatures and is therefore the first choice in applications with mastic asphalt.

Technical properties

- Design according to EN 1057

- Fire resistance: EN 13501-1-A1 (non-flammable)

- With quality mark

- Diffusion rate: 0.00 mg/m²*d after 50 years

Fields of application

- Underfloor heating with mastic asphalt screed

- Wall heating with clay plaster

Materials

cuprofrio.plus

Wieland branded copper tubes cuprofrio and cuprofrio.plus have a high level of internal cleanliness due to the individually closed tube ends and are suitable for refrigerants according to EN 12735-1.

cuprofrio tubes can be easily processed on site and conform to high quality standards with their extremely clean and dry inner surface. Close tube ends ensure the required quality even during storage and transportation.

learn more

cuprofrio.plus

cuprofrio.plus-tubes are insulated on the outside, which prevents nearly all water condensation on the outer surface of the tube.

Your benefits

- clean and dry inside surface

- standard dimensions available from stock

- good processing, easy joining, very easy to unwind and bend

- resistant, colour-fast insulation ensures consistent material properties in all weather conditions

- prevention of condensation water through insulating layer

- supplier traceability through signature

- compliance with Pressure Equipment Directive 97/23/EC

Fields of application

cuprofrio is suitable for technical gases and liquids, for example in

- chillers

- air-conditioning and refrigeration units

- heat exchangers

cuprofrio – refrigeration

Wieland branded copper tubes cuprofrio and cuprofrio.plus have a high level of internal cleanliness due to the individually closed tube ends and are suitable for refrigerants according to EN 12735-1.

cuprofrio tubes can be easily processed on site and conform to high quality standards with their extremely clean and dry inner surface. Close tube ends ensure the required quality even during storage and transportation.

learn more

Your benefits

- clean and dry inside surface

- closed tube ends in order to maintain cleanliness

- supplier traceability through signature

- standard dimensions available from stock

- good processing, easy joining, very easy to unwind and bend

- tube quality according to EN 12735-1

- compliance with Pressure Equipment Directive 2014/68/EU

Fields of application

cuprofrio is suitable for technical gases and liquids, for example in

- chillers

- air-conditioning and refrigeration units

- heat exchangers

Forms of delivery

- Coils (pancakes)

- Straight lengths of 5 m

K65 - Sustainable and efficient

two keywords that have had a decisive impact on our time and have gained in relevance in recent years, especially in refrigeration. Increased environmental awareness in society and industry has therefore led to a kind of renaissance of natural refrigerants, especially CO2. Wieland supports this turnaround with a tube system that meets the high requirements of CO2 as a refrigerant.

Wieland K65 tubes have been designed for CO2 applications in the commercial field, especially that of supermarket refrigeration systems. Wieland K65 alloy provides the mechanical strength high enough to withstand the high operating pressures of CO2. At the same time, K65 tubes have outstanding processing properties, similar to those of standard copper (Cu-DHP/C12200).

Wieland K65 tubes are offered from stock in two pressure ranges, 80 bar and 120 bar, and in dimensions ranging from 3/8” up to 2-1/8”.

All Wieland K65 tubes are available in the soft condition (R300/O61) to ensure excellent bending / flaring and collaring properties.

Other dimensions and delivery forms such as level wound coils are offered for industrial processing, in particular manufacturing of CO2 heat exchangers (evaporator/gas cooler).

More K65 products in other categories

Your benefits

- Cost reduction through weight reduction

- Proven processing technology: brazing instead of welding!

- Economical and safe installation of regrigeration systems with up to 120 bar operation pressure

- Excellent heat transfer

- Design according to EN 14276

Typical applications

- Pipelines for refrigeration systems, in particular for CO2 refrigerant, with an operation pressure of up to 120 bar

Technical properties

- Material: K65

- Operation pressure: 80 bar and 120 bar

- Condition: soft R300/O61

- Delivery form: straight lengths of 5 m

- Available dimensions: 9,52 - 53,97 mm (3/8" - 2-1/8")

- Tube ends: closed

- Usual standards: EN 14276 / EN 12735-1

Further information

cupromed – medical gas supply

The seamless drawn cupromed copper tube is used for refrigeration/air conditioning as well as for medical gas supply units according to EN ISO 7396-1. cupromed tubes in straight lengths meet the requirements according to EN 13348 and those according to EN 12735-1.

Your benefits

- clean and dry inside surface

- closed tubes ends keep the surface clean

- supplier traceability through signature

- standard dimensions available from stock

- good processing, easy joining, very easy to unwind and bend

- standard tube quality according to EN 12735-1

- compliance with Pressure Equipment Directive 2014/68/EU

- Requirements according to the PED/Pressure Equipment Directive 2014/68/EU

Fields of applications

cupromed is suitable for the transportation of technical gases and liquids as well as medical gas and vacuum in

- medical gas supply units

- refrigeration and air conditioning units

cuprogeo – geothermal energy

The seamless drawn cuprogeo tube is used for geothermal energy production. cuprogeo is designed for the use of refrigerants and gases for direct evaporation in heat pumps. The advantage of this application is that high performance can be achieved with suitable heat pumps.

Your benefits

- clean and dry inner surface

- supplier traceability through signature

- tube protected by an outside surface coating

- standard tube quality according to EN 12735-1

- requirements comply with the Pressure Equipment Directive 2014/68/EU

Fields of application

- geothermal energy

- refrigeration equipment and heat exchangers

- geothermal heat pumps with direct evaporation

FRIGOTEC Plus tubes are jacketed copper tubes with high internal cleanliness and closed ends for use in refrigeration and air conditioning. Factory applied PE insulation is 9 mm and provides continuous meter marking.

Material CU-DHP, condition R220.

FRIGOTEC Plus copper tubes are subject to a constricted carbon residue on the inner surface of the tube in accordance with EN 12735-1. The range of dimensions includes 6 × 1 mm to 22 × 1 mm and 1/4" to 7/8". The pipes are ideally connected with >B< solder fittings. The applicable standards and guidelines must be observed during planning, processing and operation. The sheathing complies with fire class E of EN 13501-1 and has a vapor diffusion >7000 μ.

Standards: EN 12735-1 | ASTM B280

FRIGOTEC® tubes are seamless drawn copper tubes for use in refrigeration and air conditioning. The inner surface of the tubes has a special degree of cleanliness. The tube ends are already sealed at the factory.

FRIGOTEC® tubes are subject to a constricted carbon residue on the inner tube surface in accordance with EN 12735-1. Due to the range of dimensions from 6 × 1 mm to 108 × 2.5 mm, systems of any size can be realized. The pipes are ideally connected with >B< solder fittings. In addition, the FRIGOTEC tubes in R250 and R290 condition in the dimensions 8 × 1 mm to 64 × 1 mm comply with EN 13348 for medical gases.

The applicable standards and guidelines must be observed during planning, processing and operation.

| Wieland | EN Designation | EN No. | ASTM UNS-No. |

|---|---|---|---|

| K20/K21/K28 | Cu-DHP | CW024A | C12200 |

| Wieland | EN Designation | EN No. | ASTM UNS-No. | JIS-No. |

|---|---|---|---|---|

| M37/M38 | CuZn37 | CW508L | C27200 | C2720 |

| Wieland | EN Designation | EN No. | ASTM UNS-No. |

|---|---|---|---|

| S40 | CuZn37Mn3Al2PbSi | CW713R | C67420 |

| S40 | CuZn37Mn3Al2PbSi | CW713R | C67420 |

| Wieland | EN Designation | EN No. | ASTM UNS-No. |

|---|---|---|---|

| B12/B21 | CuSn8P/CuSn8 | CW459K/CW453K | C52100 |

| Wieland | EN Designation | EN No. | ASTM UNS-No. |

|---|---|---|---|

| A22 | AlMgSi | AW-6060 | - |

Resources

Information material and important documents for download

Connex | Bänninger

3.56 MB

Best Team for high vacuum die casting and structural parts | wieland caro

994.2 KB

A perfect pairing for standards & low vacuum casting | wieland caro

1.24 MB

Wieland Kupral

461.26 KB

267.02 KB

Connex | Bänninger

2.57 MB

Wieland Group

429.19 KB

Wieland Group

431.49 KB

Contact person

Get in touch - Your contact person at Wieland Kupral Kft.

![]() Dr. Lukács Sándor

Dr. Lukács Sándor

Managing Director

Wieland Kupral

+36 1 436 7150

Send email

![]() Farkas János

Farkas János

Logistics

Wieland Kupral

+36 1 436 7150

Send email

![]() Csók Katalin

Csók Katalin

Administration | Accounting

Wieland Kupral

+36 1 436 7150

Send email

![]() Sándor István

Sándor István

Sales Plumbing tubes

Wieland Kupral

+36 1 436 7755

Send email

![]() Tibai Veronika

Tibai Veronika

Sales - Industrial alloys

Wieland Kupral

+36 1 436 7757

Send email

![]() Deáki Szilvia

Deáki Szilvia

Sales - Industrial alloys

Wieland Kupral

+36 1 436 7766

Send email

![]() Fischl Andrea

Fischl Andrea

Sales industrial alloys

Wieland Kupral

+36 1 436 7756

Send email

![]() Kegyes Jenő

Kegyes Jenő

Head of Warehouse & Logistics

Wieland Kupral

+36 1 436 7159

Send email

Gabor Vizhanyo

Gabor Vizhanyo

Extruded Products

Wieland Kupral

+36 1 436 7155

Send email

Wieland Kupral Kft.

Kösöntyü u. 4.

1037 Budapest

Hungary

+36 1 436 7150

kupral@wieland.com

Managing Director:

Dr. Sándor Lukács

Registered office:

Budapest

Company no.:

01-09-070819

Tax no.:

10429288-2-41

Career

Start your career at Wieland Kupral Kft.

Unleash potential.

Already know your search term? Then go ahead and use our full text search. You will get a list of all relevant results.