Wieland Caro GmbH

- Modern Stockholding

- Just-in-time

- Small lot sizes

- Cooperation based on partnership

- One-off production for specific customer requirements

- From individual components to ready-to-install parts – quality from a single source

Organization

90530 Wendelstein

Germany (UTC+1)

7:30 am - 4:30 pm

Friday

7:30 am - 1:00 pm

7:30 am - 11:45 pm

12:15 pm - 3:30 pm

Friday

7:30 am - 11:00 am

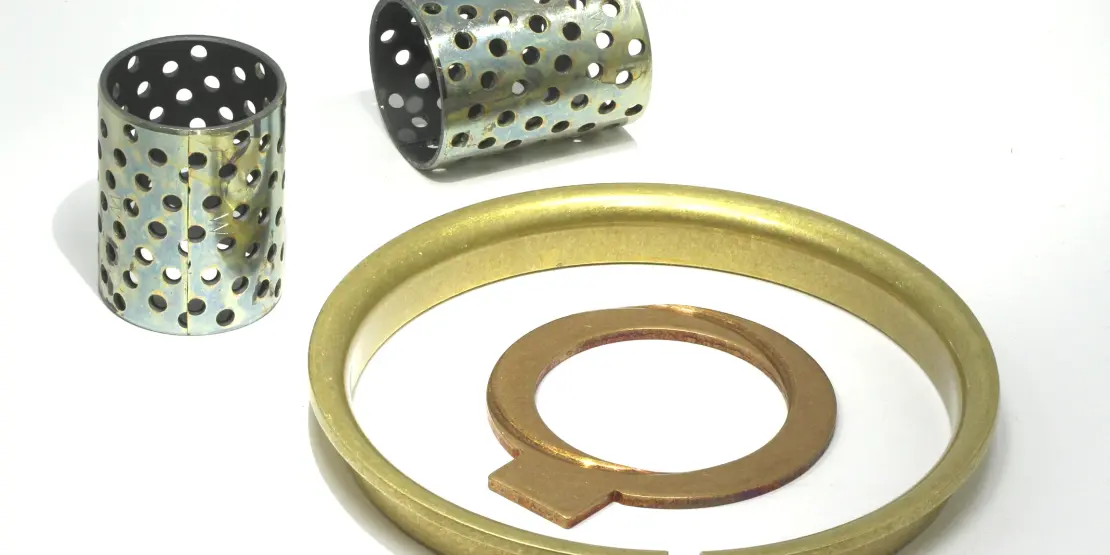

Products

Our products at a glance

Product categories

Capabilities

Resources

Information material and important documents for download

Wieland Group

431.49 KB

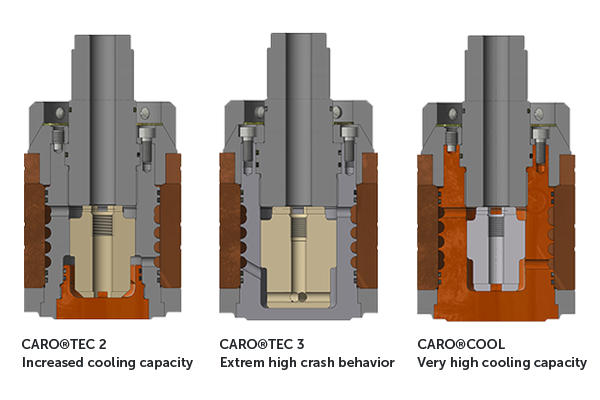

Best Team for high vacuum die casting and structural parts | wieland caro

994.2 KB

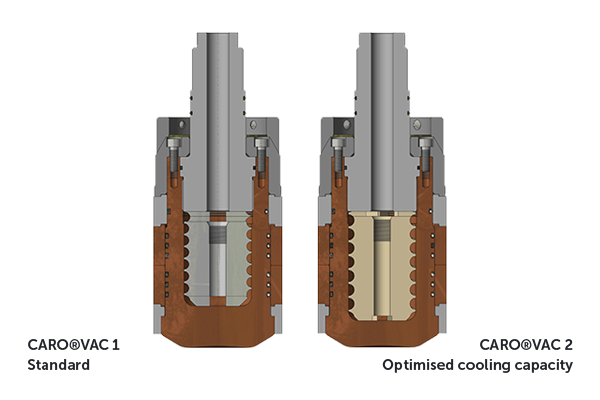

A perfect pairing for standards & low vacuum casting | wieland caro

1.24 MB

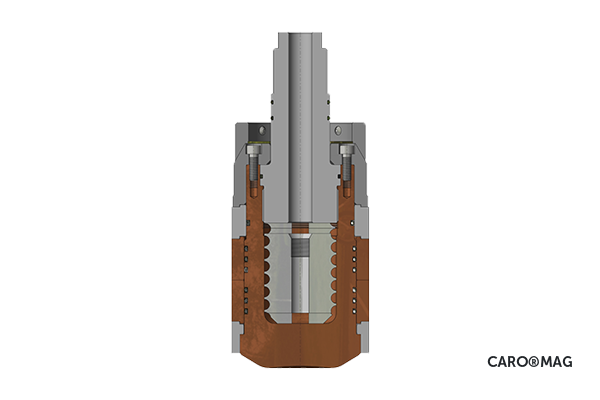

Premium shotsleeves for high-end applications | wieland caro

507.86 KB

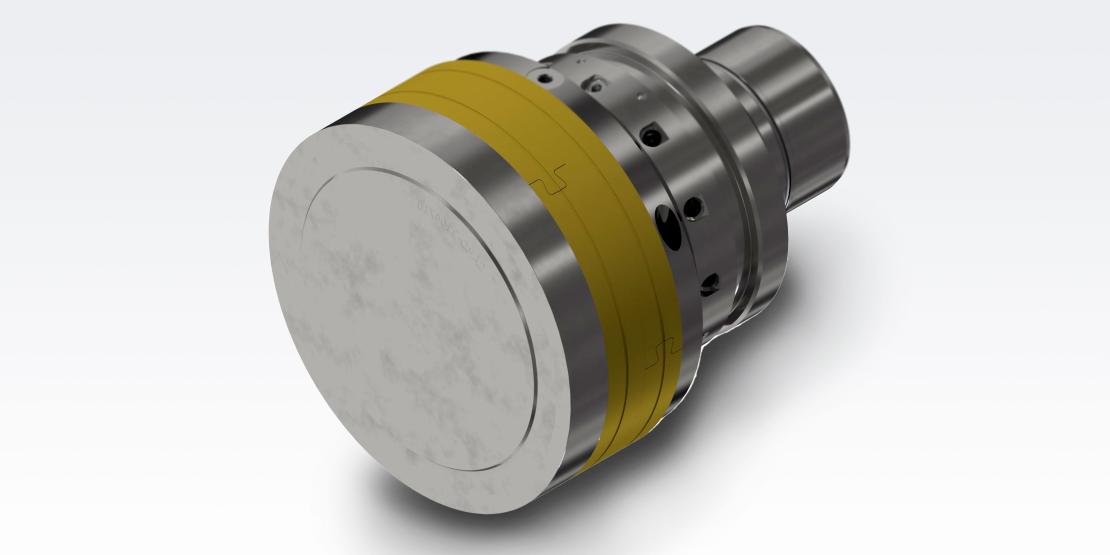

based on CARO ROD | wieland caro

880.4 KB

Trade, storage and processing of semi-finished products of non-ferrous metals.

1.72 MB

Certificate of compliance Wieland U18

816.04 KB

Alloy U18 CuAl10Fe

760.43 KB

Certificate of compliance Carobronze (Wieland B12)

818.06 KB

Wieland B12 CuSn8P

763.63 KB

Contact person

Get in touch - Your contact person at Wieland Caro GmbH

Gerhard Kanzok

Gerhard Kanzok

Sales

Wieland Caro

+49 9129 4006 16

Send email

![]() Steffen Schimanek

Steffen Schimanek

Head of Sales – Slide Bearings

Wieland Caro

+49 9129 4006 17

Send email

![]() Mareike Mailänder

Mareike Mailänder

Head of Customer Service

Wieland Caro

+49 9129 4006 25

Send email

Wieland Caro GmbH

Wilhelm-Maisel-Straße 20a

90530 Wendelstein

Germany

+49 9129 4006 0

+49 9129 4006 33

caro@wieland.com

Managing Director:

Christoph Kornblum

Registered office: Nürnberg

Court of registration: Nürnberg HRB36833

VAT identification number: DE326661277

Tax no.: 241/142/33036

Career

Start your career at Wieland Caro GmbH

Unleash potential.

Already know your search term? Then go ahead and use our full text search. You will get a list of all relevant results.