Wieland Metal Services Germany GmbH

With Wieland Metal Services Germany you have a partner with regional roots and benefit from the many years of experience in metal processing of the globally active Wieland Group.

The merger of the four companies underlines the claim and ambition of the Wieland Group to play a leading role in the trading sector in Germany as well.

- Full range supplier for copper alloys

- Wide range of processing capabilities

- State-of -the-art warehouse logistics with short delivery times

- Regionally based

- Specialized in recycling solutions

- Production of all types of drawing parts

Organization

89079 Ulm

Germany (UTC+1)

Metal Information

Current metal prices

Locations

Global proximity you can count on

Wieland Metal Services Germany GmbH

Wieland Metal Services Germany GmbH

Graf-Arco-Straße 36

89079

Ulm

Germany

Wieland Metal Services Germany GmbH | Hagen

Wieland Metal Services Germany GmbH

Verbandsstraße 99

58093

Hagen

Germany

Wieland Metal Services Germany GmbH | Trossingen

Wieland Metal Services Germany GmbH

Industriestraße 18

78647

Trossingen

Germany

Wieland Metal Services Germany GmbH | Düsseldorf

Wieland Metal Services Germany GmbH

Am Schüttenhof 5

40472

Düsseldorf

Germany

Wieland Metal Services Germany GmbH | Kornwestheim

Wieland Metal Services Germany GmbH

Albert-Einstein-Straße 1

70806

Kornwestheim

Germany

Products

Our products at a glance

Product categories

Headline

Back to product overviewMedium-high finned tubes

High finned tubes

Coaxial heat exchanger WKE | WKC

Wieland WRK

Wieland safety heat exchanger

Finned tube heat exchanger WRW

Finished parts

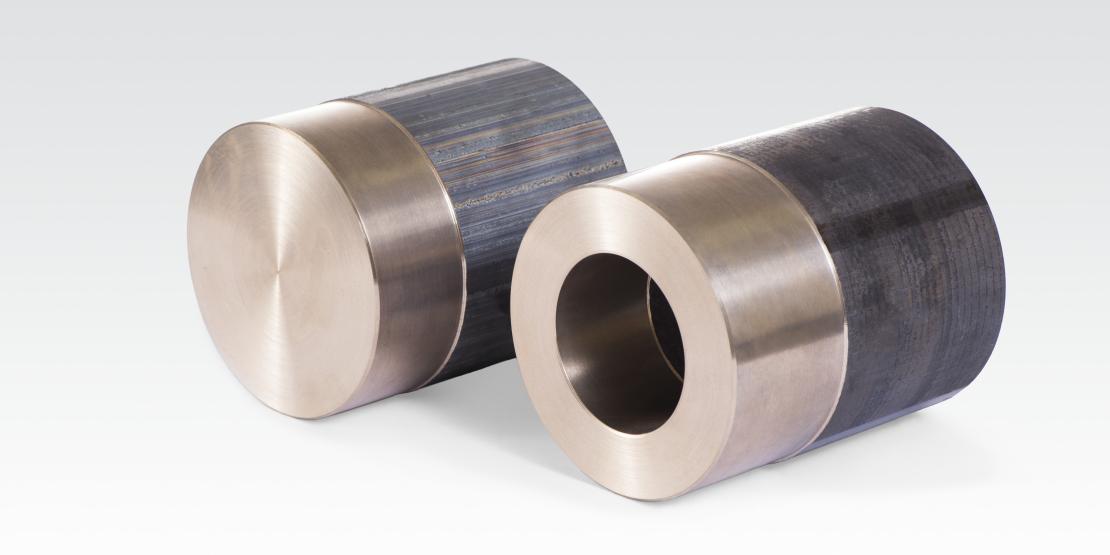

Mold Manufacturing

Ingots

High-Performance Materials for the Aviation Industry

Rods

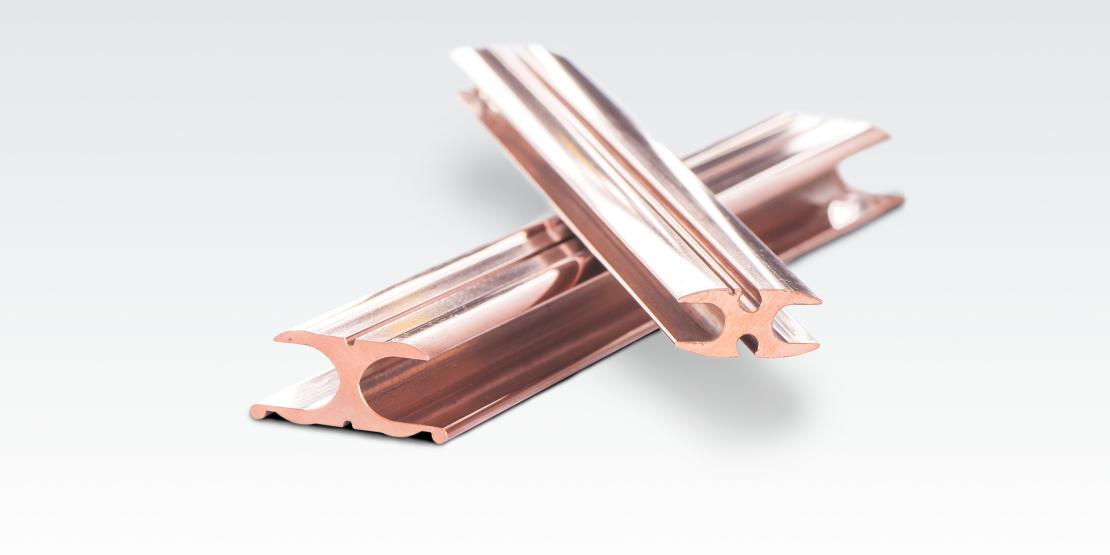

Sectional rod

ecoline®: Lead-free solutions

Precision continuous casting

Forging Stock

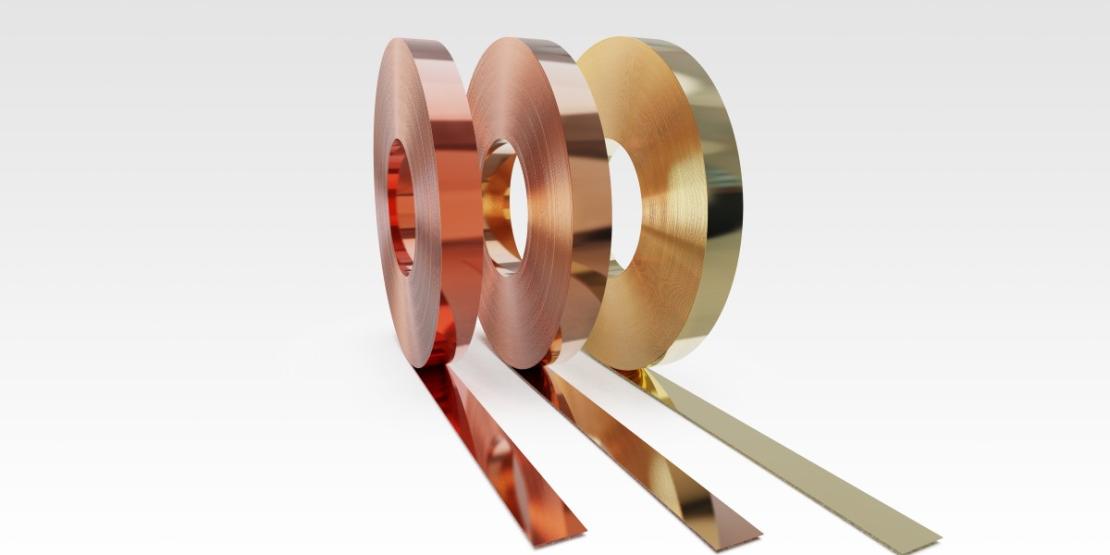

Strip

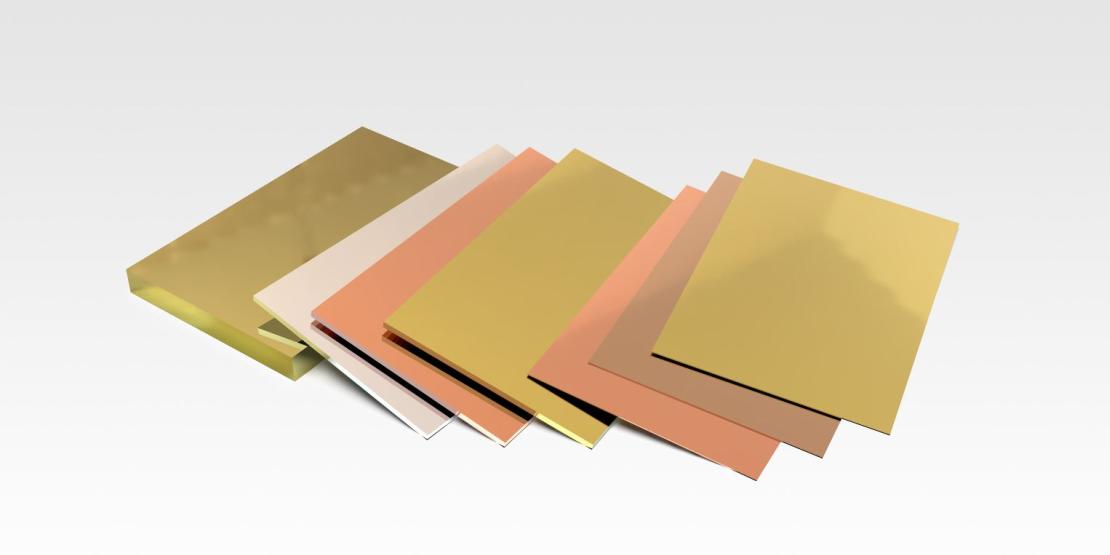

Sheets and Plates

Plumbing tubes

Tubes

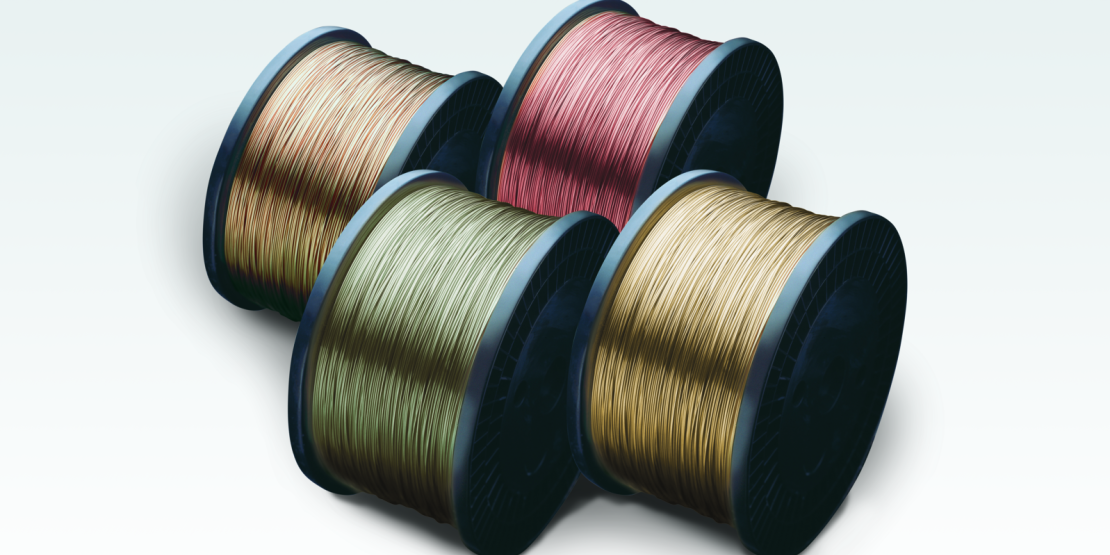

Wire

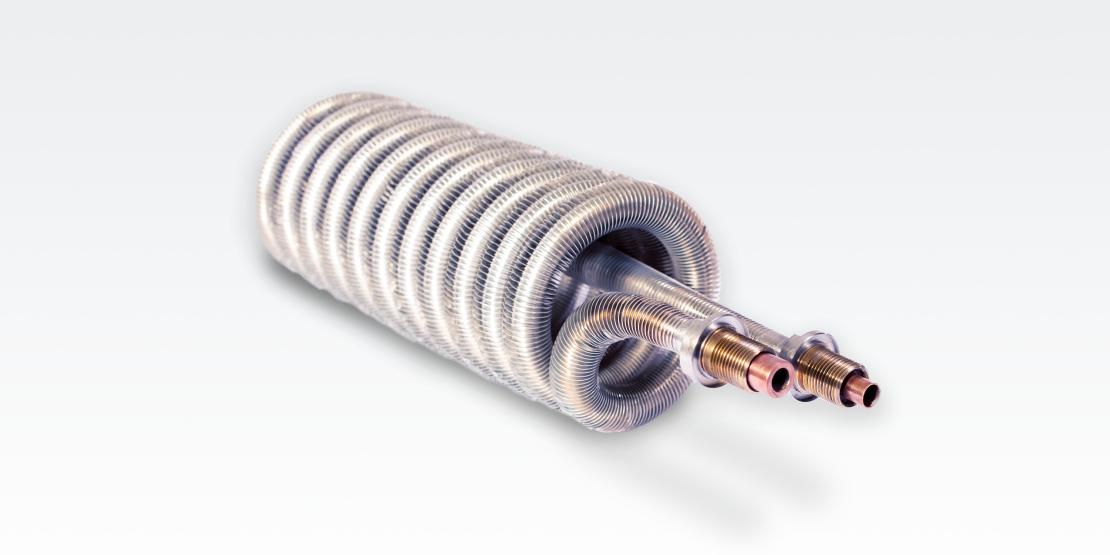

For compact coils and bent shapes

Medium-high finned tubes feature a significantly larger heat transfer surface area compared to plain tubes. They are ideal for compact and high-performance coils and shell-and-tube heat exchangers. Wieland medium-high finned tubes are a proven and robust solution for water heaters, storage tanks, refrigerant condensers, oil coolers, gas coolers or safety heat exchangers and more.

Your advantages at a glance

- High surface enlargement compared to plain tubes

- Ideal for compact and robust heat exchangers

- Excellent bending properties and processability

- Availability of various dimensions, internal structures and materials

Materials

GEWA-D finned tubes made of copper and copper alloys are available in a wide range of sizes and withstand the highest mechanical and thermic stress. They are specially made for the individual geometries of complex heat exchangers. Copper offers the highest heat conductivity of all technical metals. It is superior in processing, hygienic and a corrosion resistant solution.

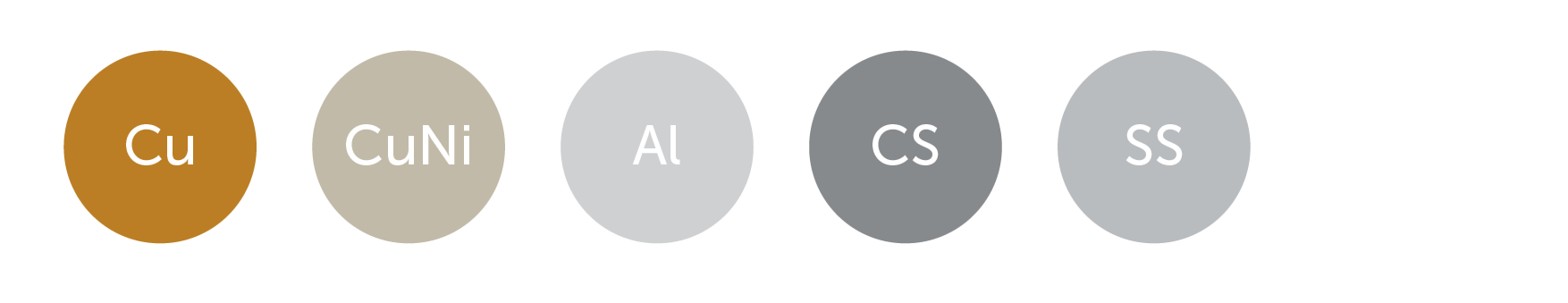

Our Materials

We offer the widest range of material in the industry and can extend it on request in case of special requirements for heat conductivity, mechanical properties or corrosion resistance. Medium-high finned tubes from Wieland Thermal Solutions are available in copper, copper-nickel, aluminium and carbon steel as well as in stainless steel in limited range.

You can find more information here

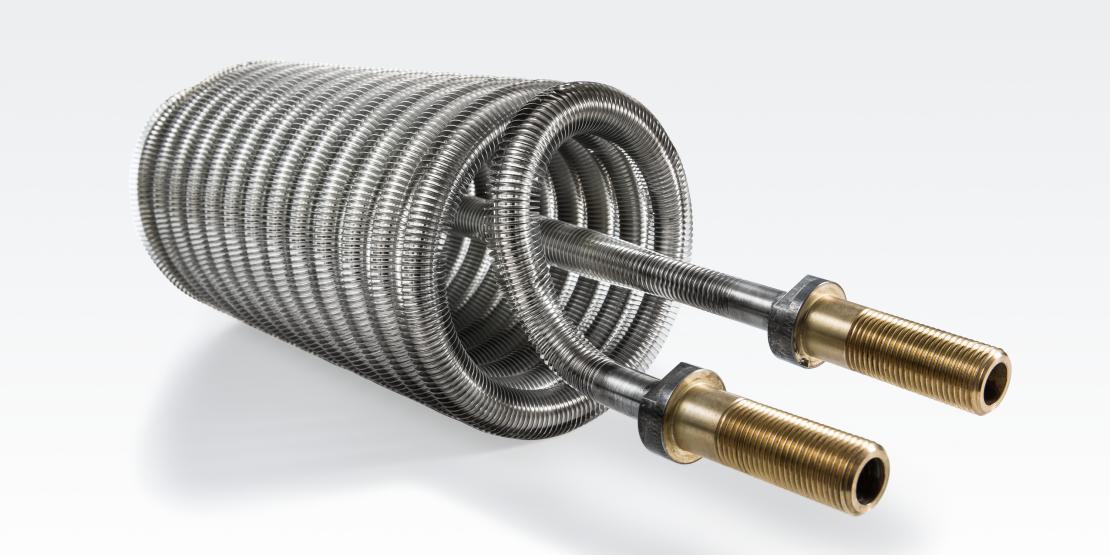

For highest efficiency in controlling the temperature of gases and liquids

High-finned tubes have a much greater outer surface area than smooth tubes. This allows for particularly compact designs. Thanks to their high, thin fins, these tubes perform particularly well in the heating and cooling of liquids and gases, making them an excellent choice for applications in heating technology, as well as in machinery and plant engineering.

Your advantages at a glance

- Highest surface enlargement compared to plain tubes (up to factor 18)

- Enables particularly compact and robust designs

- Available in straight lengths or as coiled heat exchanger

- Also available as bimetallic version GEWA-HB

Materials

GEWA-H tubes are available in a wide variety of sizes, either in straight sections or as coiled heat exchangers. They are primarily used as heat exchangers in gas boilers and as oil and gas coolers in applications related to machinery and plant engineering.

GEWA-HB tubes are high-finned tubes with a fixed inner tube made of a different material. This allows for more corrosion resistant (premium) materials to be used in combination with other, less expensive materials.

Our Materials

We offer you a broad portfolio of materials and can expand our offering at any time to meet your specific needs regarding thermal conductivity, mechanical properties, or corrosion resistance. High-finned GEWA-H tubes made by Wieland Thermal Solutions are already available in copper, copper-nickel and aluminum.

In the GEWA-HB tube materials like carbon steel, stainless steel, titanium or almost any other material like brass and nickel can be used for the inner tube.

You can find more information here

In coaxial heat exchangers, fluids are ideally conducted in counter-flow directions. The Wieland WKE and WKC series have been optimized for the condensation or evaporation of refrigerants and are used in reciprocating chillers and heat pumps.

Your advantages at a glance

- High specific power due to optimized inner tubes

- Flow guidance in counterflow

- Insensitive to frost

- Low fouling tendency

- Long service life

- Reversible operation possible

- Standard designs from stock

You can find more information here

Data sheet WKC | WKE

Our wholesaler for standard heat exchanger

Calculate your coaxial heat exchanger directly online:

ThermalX

WRK finned tube heat exchangers are suitable for efficient direct condensation and evaporation in heat pump buffer tanks. The inner grooved surface of the used finned tubes optimize the heat transfer. Thus highest COP-values are possible even with smallest temperature differences.

Your advantages at a glance

- Efficient: Highest COP values due to direct integration of the heat exchanger in the storage tank

- Filling volume optimized: Smallest refrigerant volumes due to compact design

- Easy handling: Easy replacement and maintenance

You can find more information here

Hygienic and compact: Wieland Safety Heat Exchangers are ideal for the direct heating of water for domestic use by condensing the refrigerant within the tank. The double-walled model offers additional safety against contamination and complies with the guidelines for ensuring the quality of drinking water.

4 good reasons for the Wieland safety heat exchanger series

- Cost-effective | Benefit from higher performance with the lowest refrigerant and material consumption!

- Efficient | Achieve the highest COP values according to DIN EN 16147 by installing the heat exchanger directly in the storage tank.

- Safe | Rely on absolutely reliable media separation through double tubes

- Easy handling | Reduce your effort for installation and replacement.

You can find more information here

More about direct condensation in the storage tank

Data sheet Safety Heat Exchanger

Our wholesaler for standard heat exchanger

Storage heating, circulation heating of domestic water, protecting solid fuel boilers from overheating, or controlling the temperature of oils and emulsions: With our WRW series of heat exchangers, you are putting your trust in highly developed, compact solutions that are ready to install.

Your advantages at a glance

- Compact design due to high thermal conductivity of copper combined with increased heat transfer area

- Proven corrosion resistance

- Retrofittable due to compact spiral design

- Standard designs from stock

You can find more information here

Do you need finished parts according to drawings? Here, too, we are your competent supplier.

We offer you for example:

- electrodes and other accessories for resistance welding technology

- input material for die-cast pistons and finished pistons

- semi-finished products made of highly conductive copper-based materials for tool and mould construction

- parts made of refractory metals

Components from Elmedur

Our Elmedur materials are particularly versatile. We produce parts from them according to drawings - and of course also individual parts. All according to your wishes and requirements.

Electrodes

No matter which electrodes you need: Among our large selection of standard electrodes you will find the right one for your purposes. We manufacture electrodes from hardenable copper materials, which are very hard and at the same time highly conductive. They are ideal for applications in which high electrical currents are transmitted under high mechanical loads.

Components made of high-melting metals

From our refractory metals molybdenum, TZM, tungsten and tantalum we manufacture parts according to drawings as well as individual parts. As the metals are very easy to process, they are ideal for a wide range of applications.

Aluminum Bronze – Plastic Injection Molding Dies for Mold Construction

Benefits

- High tensile and fatigue strength

- Extreme toughness, even at high temperatures up to 400°C

- Thermal conductivity increases as temperature increases

- Excellent resistance to scaling, erosion, and cavitation pitting

- Excellent corrosion resistance, especially in environments with high humidity

- Easy mechanical processing

- Good sliding properties

- Can be used in the delivered condition, no hardening required, thus no warping like with steel

- MIG and TIG welding possible

- Reduced cycle times and production costs by eliminating costly coolant duct systems

Stock/Quality

- We saw to your desired dimensions – fast, clean, and true to size!

- sheets with polished surfaces starting at 4 mm thickness, with milled surfaces from 27 mm to 145 mm thickness

- Pressed bars with edges, straightened: flat from 20x10mm to 160x52mm, square from 20x20mm to 90x90mm

- 100% ultrasonically tested

- Thermally relaxed

- Flatness max. 3 mm/m

Characteristics

| Alcaro®AB4S/Sheets | Alcaro®AB4S/Edged Rods | |

| Thermal Conductivity W/m×K at approx. room temperature | 50 | 50 |

| Thermal Conductivity W/m × K at approx. 300°C | 73 | 73 |

| Tensile Strength Rm N/mm² approx. | 720 | 720 |

| Yield Strength Rp0.2 N/mm² ca. | 320 – 370 | 480 – 530 |

| Brinell Hardness HB ca. | 200 | |

| Vickers Hardness HV ca. | 180 | |

| Ultimate Strain A5 % approx. | 20 | 10 |

| Expansion Coefficient 10-6/K | 17 | 17 |

Machining information

Material: Alcaro®AB4S/Sheets

| Turning/Milling | Excellent |

| Polishability | Excellent |

| Wire EDM | Excellent |

Die-Sinking EDM | Good |

| Thread Cutting | Good, Sharp |

| Welding (WIG) | Good |

| Galvanic Surface Treatment | Good |

| Drilling | Good |

| Wieland | EN Designation | EN-No. | ASTM-UNS-No. |

|---|---|---|---|

| Elmedur B2 | CuBe2 | CW101C | C17200 |

| Elmedur HA | CuCoNiBe | CW103C | ~C17500 |

| Elmedur HC | CuNi2Be | CW110C | C17510 |

| Elmedur NCS | CuNi2SiCr | ~CW111C | C18000 |

| Elmedur X | CuCrZr | CW106C | C18150 |

Ecocast Properties

Wieland | EN Designation | EN-No. | ASTM-UNS-No. |

|---|---|---|---|

CuZn21Si3P-C | CC768S | C87850 | |

| CuZn21Si3P-B | CB768S |

|

High mechanical strength

Its grain refiner ensures an extremely fine grain size, facilitating even distribution of force throughout the entire structure. The result: strength and hardness otherwise only known in steel, even with thin, weight-reducing wall thicknesses.

Improved casting

Thanks to its fine-grained structure, Ecocast is ideal for filigree components.

Reduced waste

In every situation where you were previously dependent on red brass for filigree shapes, the high amount of waste of this conventional material is eliminated with Ecocast.

Excellent machinability

Ecocast and its special chemical composition also makes reworking cast parts through machining, grinding, polishing, or coating safe, precise, and cost-effective.

Top-rate corrosion resistance

The fine-grained structure through and through also means minimal dezincification on the surface due to touching, oxidation, or cleaning.

The future is lead-free

Secure your market lead: with Ecocast you can design and equip your products for the future, too. After all, many countries and various customers are already implementing strict regulations concerning the use of lead-free materials.

Universal

Ecocast can be cast both in ingot molds and in sand. The material is standardized under CC768S in EN 1982.

Ecocast: The New Material for Sanitary Installations

Ecocast is the perfect material for sanitary installations, not just for meeting drinking water regulations in the future, but also mainly for meeting current cost-efficiency requirements. Thanks to its high mechanical strength, Ecocast achieves wall thicknesses that help significantly reduce weight and save on materials and costs without compromising on stability. Moreover, Ecocast can handle forces (or moments) that until now have only been reserved for steel. The fine-grained structure and lack of lead produce surfaces that are aesthetically impeccable when Ecocast parts are coated.

Functional Properties, Long-Lasting Look

The extremely corrosion-resistant brass material Ecocast has a premium golden surface that is especially long -lasting, making it suitable even for frequently used objects and room fixtures made from cast parts. Ecocast also has high color stability and resistance to degradation caused by contact, air humidity, or intensive cleaning, which increases hygiene safety in hospitals, clinics, and nursing care institutions. - The innovative cast material from Wieland retains its functional properties even with heavy day-to-day use.

We supply aerospace grade alloys and special alloys of the highest quality. For the aerospace industry Wieland Prometa offers you high-quality semi-finished products in a wide range of dimensions.

The outstanding mechanical properties and a very good machinability make our products ideal materials for bushings, bearings and connections for the highest loads.

Brochure: Ready for takeoff

Materials

| Alloy Number | Composition | Temper | Standards | |

|---|---|---|---|---|

| C62300 | CuAl8Fe3 | HR50/ O30 | AMS 4635 | |

| C62400 | CuAl10Fe3 | ASTM B150 | ||

| C63000 | CW307G | CuAl10Ni5Fe4 | HR50/ TQ50 | EN 12163 |

| C63020 | CW307G CA104 | CuAl10Ni5Fe4 | HR50/ TQ30 | EN 12163 |

| C63200 | CuAl9Ni4Fe3 | TQ50 | ASTM B150 | |

C95510 | CuAl10Ni5Fe2 | TQ50 | AMS 4880 | |

C95520 | CuAl11Ni5Fe4 | TQ50 | AMS 4881 | |

CuAl9Ni5Fe4 | DEF NES 02-833 | |||

Further alloys on request.

| Alloy Number | Composition | Standards | |

|---|---|---|---|

| C51000 | CW451K | CuSn5 | AMS 4625 |

C52100 | CW459K | CuSn8P | PB 104 |

Further alloys on request.

| Alloy Number | Composition | Standards | |

|---|---|---|---|

C65620 | CuZn3Si3Fe2Mn | AMS 4616 F&G | |

C70260 | CW111C | CuNi2Si | CARODUR®-2 |

Further alloys on request.

Materials

| Wieland | EN Designation | EN No. | ASTM UNS-No. |

|---|---|---|---|

| K12 | Cu-HCP | CW021A | C10300 |

| K18/K32 | Cu-ETP | CW004A | C11000 |

| K18/K32 | Cu-ETP | CW004A | C11000 |

| K20/K21/K28 | Cu-DHP | CW024A | C12200 |

| K30 | Cu-OF | CW008A | C10200 |

| Wieland | EN Designation | EN No. | ASTM UNS-No. |

|---|---|---|---|

| Elmedur B2 | CuBe2 | CW101C | C17200 |

| Elmedur HA | CuCoNiBe | CW103C | ~C17500 |

| Elmedur HC | CuNi2Be | CW110C | C17510 |

| Elmedur NCS | CuNi2SiCr* | ~CW111C* | C18000 |

| Elmedur X | CuCrZr | CW106C | C18150 |

| Elmedur Z | CuZr | CW120C | C15000 |

| K41 | CuNi1Pb1P* | - | C19150 / C19160 |

| K44 | CuNi1Pb0.6P* | - | C19140 / C19150 |

| K52 | CuNi2Si | CW111C | C70260 |

| K53 | CuNi2SiS* | - | - |

| K54 | CuNi2SiCr* | - | C81540 |

| K60 | CuCr1Zr | CW106C | C18150 |

| K61 | CuCr1Zr | CW106C | C18200 |

| K65 | CuFe2P | CW107C | C19400 |

| K81 | CuSn0,15 | CW117C | C14415 |

| KC1 | CuPb1P | CW113C | C18700 |

| KD3 | CuTeP | CW118C | C14500 |

| eco KS2® | CuSP | CW114C | C14700 |

| Wieland | EN Designation | EN No. | ASTM UNS-No. | JIS-No. |

|---|---|---|---|---|

| Z11 | CuZn35Pb1 | CW600N | C34000 | |

| Z12 | CuZn35Pb2 | CW601N | C34200 / C34500 | |

| Z14 | CuZn37Pb2 | CW606N | C35300 | |

| Z21 | CuZn38Pb2 | CW608N | C3713 | |

| Z23 | CuZn36Pb3 | CW603N | C36000 | |

| Z29 | CuZn39Pb2 | CW612N | C37700 | |

| Z31/Z41/Z48 | CuZn40Pb2 | CW617N | C38000 | |

| Z32/Z33 | CuZn39Pb3 | CW614N | C38500 | |

| Z40 | CuZn43Pb2Al | CW624N | - | |

| Z43 | CuZn33Pb1AlSiAs | CW725R | - | |

| Z45/Z46 | CuZn36Pb2As | CW602N | C35330 |

| Wieland | EN Designation | EN No. | ASTM UNS-No. |

|---|---|---|---|

| L10/L13/L15 | CuNi10Fe1Mn | CW352H | C70600 |

| L30 | CuNi30Mn1Fe | CW354H | C71500 |

| Wieland | EN Designation | EN No. | ASTM UNS-No. | JIS-No. |

|---|---|---|---|---|

| M10 | CuZn10 | CW501L | C22000 | C2200 |

| M15/M16/M17 | CuZn15 | CW502L | C23000 | |

| M30/M34 | CuZn30 | CW505L | C26000 | C2600 |

| M36 | CuZn36 | CW507L | C26800 / C27000 | C2700 |

| M37/M38 | CuZn37 | CW508L | C27200 | C2720 |

| eco M43® | CuZn38As | CW511L | C27453 | |

| eco M57® | CuZn42 | CW510L | - | |

| eco M58® | CuZn42 | CW510L | - |

| Wieland | EN Designation | EN No. | ASTM UNS-No. |

|---|---|---|---|

| S31 | CuZn31Si1 | CW708R | - |

| S35 | CuZn35Ni3Mn2AlPb | CW710R | - |

| S40 | CuZn37Mn3Al2PbSi | CW713R | C67420 |

| eco S34® | CuZn34Mn2SiAlNi* | - | C67340 |

| eco ST2 | CuZn35Sn1P | CW727R | - |

| eco ST3 | CuZn29Si1SnP | CW729R | - |

| eco ST4 | CuZn42 | CW510L | - |

| eco SW1® | CuZn21Si3P | CW724R | C69300 |

| eco SZ2® | CuZn36Si1P | CW726R | C68370 |

| eco SZ3® | CuZn40SiP | CW728R | - |

| eco SZ4® | CuZn42 | CW510L | C28500 |

| eco SZ5® | CuZn40 | CW509L | C27450 |

| Wieland | EN Designation | EN No. | ASTM UNS-No. |

|---|---|---|---|

| B06 | CuSn6 | CW452K | C51900 |

| B09/B10 | CuSn8 | CW453K | C52100 |

| B12/B21 | CuSn8P/CuSn8 | CW459K/CW453K | C52100 |

| B44/B45 | CuSn4Pb4Zn4 | CW456K | C54400 |

| BV9 | CuSn6 | CW452K | C51900 |

| eco BS4® | CuSn5NiPS* | - | - |

| Wieland | EN Designation | EN No. | ASTM UNS-No. |

|---|---|---|---|

| U33 | CuAl10Ni5Fe4 | CW307G | C63000 |

| U35 | CuAl10Ni5Fe4 | CW307G | C63020 |

| U36 | CuAl11Fe6Ni6 | CW308G | - |

| U39 | Cu Al10Fe3Mn2 | CW306G | - |

| Wieland | EN Designation | EN No. | ASTM UNS-No. |

|---|---|---|---|

| N29 | CuNi18Zn20 | CW409J | - |

| N31 | CuNi7Zn39Pb3Mn2 | CW400J | - |

| N32 | CuNi12Zn30Pb1 | CW406J | - |

| N37 | CuNi18Zn19Pb1 | CW408J | - |

| N48 | CuNi12Zn38Mn5Pb2 | CW407J | - |

| eco N59® | CuNi9Zn41FeMn | - | - |

| Wieland | EN Designation | EN No. | ASTM UNS-No. |

|---|---|---|---|

| A01 | AlMgSiBi | AW-6026 | - |

| A02 | AlCu6BiPb | AW-2011 | - |

| A03 | AlCu4MgSi(A) | AW-2017A | - |

| A07 | AlZn5,5MgCu | AW-7075 | - |

| A11 | AlSi1Sn1MgBi | AW-6023 | - |

| A12 | AlMgSiPb | AW-6012 | - |

| A13 | AlMg3 | AW-5754 | - |

| A14 | AlMg4,5Mn0,7 | AW-5083 | - |

| A22 | AlMgSi | AW-6060 | - |

| A32 | AlSi1MgMn | AW-6082 | - |

| Wieland | EN Designation | EN No. | ASTM UNS-No. |

|---|---|---|---|

| High Density (HD) | - | - | - |

| Molybdän (Mo) | - | - | - |

| Molybdän-Lanthan (ML) | - | - | - |

| Niob (Nb) | - | - | - |

| Rhenium (Re) | - | - | - |

| Tantal (Ta) | - | - | - |

| Titan (Ti) | - | - | - |

| Titan-Zirkon-Molybdän (TZM) | - | - | - |

| Wolfram (W) | - | - | - |

| Wolfram-Kupfer (TUCO) | - | - | - |

| Wolfram-Rhenium | - | - | - |

| Zirkonium (Zr) | - | - | - |

| Wieland | EN Designation | EN No. | ASTM UNS-No. |

|---|---|---|---|

| Elmedur NCS | CuNi2SiCr* | ~CW111C* | C18000 |

| Elmedur X | CuCrZr | CW106C | C18150 |

| Wieland | EN Designation | EN No. | ASTM UNS-No. |

|---|---|---|---|

| Z31/Z41/Z48 | CuZn40Pb2 | CW617N | C38000 |

| Z32/Z33 | CuZn39Pb3 | CW614N | C38500 |

| Wieland | EN Designation | EN No. | ASTM UNS-No. |

|---|---|---|---|

| eco ST2 | CuZn35Sn1P | CW727R | - |

| eco ST3 | CuZn29Si1SnP | CW729R | - |

| eco ST4 | CuZn42 | CW510L | - |

| Wieland | EN Designation | EN No. | ASTM UNS-No. |

|---|---|---|---|

| A22 | AlMgSi | AW-6060 | - |

Learn more about

Wieland ecoline

From Europe’s largest copper alloy foundry in Vöhringen/Iller (Germany), we can offer you far in excess of a hundred different copper materials. These include not only a wide range of continuous castings like tubes and rods, but also shaped rods and sections of complex geometries. At the same time, our flexibility ensures the prompt realisation of your special custom wishes.

Materials

| Wieland | EN Designation | EN No. | ASTM UNS-No. |

|---|---|---|---|

| G05 | CuSn5Zn5Pb5-C-GC | CC491K | - |

| G07/G08 | CuSn7Zn4Pb7-C | CC493K | - |

| G10 | CuSn10-C | CC480K | - |

| G12/G13 | CuSn12-C | CC483K | - |

| G12/G13 | CuSn12-C | CC483K | - |

| G21 | CuSn10Pb10-C-GC | CC495K | - |

| G22 | CuSn7Pb15-C | CC496K | - |

| G91 | CuSn11Pb2-C-GC | CC482K | - |

| GA1 | CuSn11Pb2-C-GC | CC481K | - |

| GB1 | CuSn12Ni2-C | CC484K | - |

| GD1 | CuSn5Zn5Pb2-C-GC | CC499K | - |

| eco GS1® | CuSn4Zn2PS-C-GC* | - | - |

Wieland hot stamping rods

Good forging results can be obtained only when all links in the process chain have been matched to each other to the optimal effect. With Wieland hot stamping rods you are offered a forging stock which comprehensively fulfils these requirements. Your benefits: uniform dark surface for reproducible processing properties, tight diameter tolerances in the drawn size range, and hence precise configuration of the slug weight.

Materials

| Wieland | EN Designation | EN No. | ASTM UNS-No. |

|---|---|---|---|

| Elmedur B2 | CuBe2 | CW101C | C17200 |

| Elmedur HA | CuCoNiBe | CW103C | ~C17500 |

| Elmedur HC | CuNi2Be | CW110C | C17510 |

| Elmedur NCS | CuNi2SiCr* | ~CW111C* | C18000 |

| Elmedur X | CuCrZr | CW106C | C18150 |

| Wieland | EN Designation | EN No. | ASTM UNS-No. | Dimensions | Temper |

|---|---|---|---|---|---|

| Z31/Z41/Z48 | CuZn40Pb2 | CW617N | C38000 | ||

| Z32/Z33 | CuZn39Pb3 | CW614N | C38500 | Ø 16 – 140 mm | M |

| Z32/Z33 | CuZn39Pb3 | CW614N | C38500 | Ø 16 – 140 mm | |

| Z45/Z46 | CuZn36Pb2As | CW602N | C35330 | Ø 16 – 140 mm |

Learn more

Strips for connector

Hot dip tinned copper and copper-alloy strip

Strip for semiconductor packages

Materials

| Wieland | EN Designation | EN No. | ASTM UNS-No. | JIS-No. |

|---|---|---|---|---|

| K09 | Cu-OFE | CW009A | C10100 | C1011 |

| K11 | Cu-OF | CW008A | C10200 | |

| K12 | Cu-HCP | CW021A | C10300 | |

| K14 | Cu-PHC | CW020A | C10300 | |

| K19 | Cu-DHP | CW024A | C12200 | C1220 |

| K32 | Cu-ETP | CW004A | C11000 | C1100 |

| Wieland | EN Designation | EN No. | ASTM UNS-No. |

|---|---|---|---|

| Elmedur X | CuCrZr | CW106C | C18150 |

| K65 | CuFe2P | CW107C | C19400 |

| K80 | CuFe0,1P* | - | C19210 |

| K81 | CuSn0,15 | CW117C | C14415 |

| Wieland | EN Designation | EN No. | ASTM UNS-No. |

|---|---|---|---|

| K55 | CuNi3Si1Mg* | - | C70250 |

| K57 | CuNi1Co1Si* | - | C70350 |

| K73 | CuNi1ZnSi* | - | C19005 |

| K75 | CuCrSiTi* | - | C18070 |

| K76 | CuNiSiP* | - | C19010 |

| K82 | - | - | C15100 |

| K88 | CuCrAgFeTiSi* | - | C18080 |

| Wieland | EN Designation | EN No. | ASTM UNS-No. | JIS-No. | Temper |

|---|---|---|---|---|---|

| M42 | CuZn42 | CW510L | - | ||

| Z21 | CuZn38Pb2 | CW608N | C3713 | ||

| Z30 | CuZn39Pb2 | CW612N | C37700 | R360/R490/R560 F49/F59 | |

| Z30 | CuZn39Pb2 | CW612N | C37700 |

| Wieland | EN Designation | EN No. | ASTM UNS-No. | JIS-No. |

|---|---|---|---|---|

| M05 | CuZn5 | CW500L | C21000 | C2100 |

| M10 | CuZn10 | CW501L | C22000 | C2200 |

| M15 | CuZn15 | CW502L | C23000 | C2300 |

| M15 | CuZn15 | CW502L | C23000 | C2300 |

| M20 | CuZn20 | CW503L | C24000 | C2400 |

| M28 | CuZn28 | CW504L | C25600 | |

| M30 | CuZn30 | CW505L | C26000 | C2600 |

| M33 | CuZn33 | CW506L | C26800 | C2680 |

| M36 | CuZn36 | CW507L | C26800 / C27000 | C2700 |

| M37 | CuZn37 | CW508L | C27200 | C2720 |

| M38 | CuZn37 | CW508L | C27200 | C2720 |

| Wieland | EN Designation | EN No. | ASTM UNS-No. | JIS-No. |

|---|---|---|---|---|

| S12 | CuSn3Zn9 | CW454K | C42500 | C4250 |

| S23 | CuZn23Al3Co | CW703R | C68800 |

| Wieland | EN Designation | EN No. | ASTM UNS-No. | JIS-No. |

|---|---|---|---|---|

| B14 | CuSn4 | CW450K | C51100 | |

| B15 | CuSn5 | CW451K | C51000 | |

| B16 | CuSn6 | CW452K | C51900 | |

| B18 | CuSn8 | CW453K | C52100 | C5212 |

| B31 | CuSn2Fe0,1P* | - | C50715 |

| Wieland | EN Designation | EN No. | ASTM UNS-No. | JIS-No. |

|---|---|---|---|---|

| N12 | CUNi12Zn24 | CW403J | C75700 | |

| N17 | CuNi18Zn27 | CW410J | C77000 | C7701 |

| N18 | CuNi18Zn20 | CW409J | C76400 | C7521 |

| N39 | CuNi12Zn25Pb1 | CW404J | C79200 | |

| N41 | CuNi7Zn37Pb1 | - | - |

| Wieland | EN Designation | EN No. | ASTM UNS-No. |

|---|---|---|---|

| A05 | Al99,5 | AW-1050A | - |

| A13 | AlMg3 | AW-5754 | - |

| A32 | AlSi1MgMn | AW-6082 | - |

| A75 | AW-6082 | - | - |

| Wieland | EN Designation | EN No. | ASTM UNS-No. | JIS-No. | Dimensions | Temper |

|---|---|---|---|---|---|---|

| K11 | Cu-OF | CW008A | C10200 | R220/R240/R290/R360 F20/F25/F32 | ||

| K12 | Cu-HCP | CW021A | C10300 | R220/R240/R290/R360 F20/F25/F33 | ||

| K14 | Cu-PHC | CW020A | C10300 | R220/R240/R290/R360 F20/F25/F34 | ||

| K18 | Cu-ETP | CW004A | C11000 | |||

| K19 | Cu-DHP | CW024A | C12200 | C1220 | R220/R240/R290/R360 F20/F25/F31 | |

| K32 | Cu-ETP | CW004A | C11000 | C1100 | on request |

| Wieland | EN Designation | EN No. | ASTM UNS-No. |

|---|---|---|---|

| Elmedur B2 | CuBe2 | CW101C | C17200 |

| Elmedur HA | CuCoNiBe | CW103C | ~C17500 |

| Elmedur HC | CuNi2Be | CW110C | C17510 |

| Elmedur NCS | CuNi2SiCr* | ~CW111C* | C18000 |

| Elmedur X | CuCrZr | CW106C | C18150 |

| Wieland | EN Designation | EN No. | ASTM UNS-No. |

|---|---|---|---|

| K55 | CuNi3Si1Mg* | - | C70250 |

| K57 | CuNi1Co1Si* | - | C70350 |

| K73 | CuNi1ZnSi* | - | C19005 |

| K75 | CuCrSiTi* | - | C18070 |

| K76 | CuNiSiP* | - | C19010 |

| K82 | - | - | C15100 |

| K88 | CuCrAgFeTiSi* | - | C18080 |

| Wieland | EN Designation | EN No. | ASTM UNS-No. | JIS-No. |

|---|---|---|---|---|

| Z21 | CuZn38Pb2 | CW608N | C3713 | |

| Z29 | CuZn39Pb2 | CW612N | C37700 | |

| Z30 | CuZn39Pb2 | CW612N | C37700 |

| Wieland | EN Designation | EN No. | ASTM UNS-No. | JIS-No. |

|---|---|---|---|---|

| M05 | CuZn5 | CW500L | C21000 | C2100 |

| M10 | CuZn10 | CW501L | C22000 | C2200 |

| M15 | CuZn15 | CW502L | C23000 | C2300 |

| M20 | CuZn20 | CW503L | C24000 | C2400 |

| M30 | CuZn30 | CW505L | C26000 | C2600 |

| M33 | CuZn33 | CW506L | C26800 | C2680 |

| M36 | CuZn36 | CW507L | C26800 / C27000 | C2700 |

| M37 | CuZn37 | CW508L | C27200 | C2720 |

| M38 | CuZn37 | CW508L | C27200 | C2720 |

| Wieland | EN Designation | EN No. | ASTM UNS-No. | JIS-No. |

|---|---|---|---|---|

| B06 | CuSn6 | CW452K | C51900 | |

| B14 | CuSn4 | CW450K | C51100 | |

| B15 | CuSn5 | CW451K | C51000 | |

| B16 | CuSn6 | CW452K | C51900 | |

| B18 | CuSn8 | CW453K | C52100 | C5212 |

| Wieland | EN Designation | EN No. | ASTM UNS-No. |

|---|---|---|---|

| U33 | CuAl10Ni5Fe4 | CW307G | C63000 |

| Wieland | EN Designation | EN No. | ASTM UNS-No. | JIS-No. |

|---|---|---|---|---|

| N12 | CUNi12Zn24 | CW403J | C75700 | |

| N17 | CuNi18Zn27 | CW410J | C77000 | C7701 |

| N18 | CuNi18Zn20 | CW409J | C76400 | C7521 |

| N39 | CuNi12Zn25Pb1 | CW404J | C79200 | |

| N41 | CuNi7Zn37Pb1 | - | - |

| Wieland | EN Designation | EN No. | ASTM UNS-No. |

|---|---|---|---|

| A03 | AlCu4MgSi(A) | AW-2017A | - |

| A05 | Al99,5 | AW-1050A | - |

| A07 | AlZn5,5MgCu | AW-7075 | - |

| A13 | AlMg3 | AW-5754 | - |

| A14 | AlMg4,5Mn0,7 | AW-5083 | - |

| A32 | AlSi1MgMn | AW-6082 | - |

| A75 | AW-6082 | - | - |

| A86 | - | - | - |

| Wieland | EN Designation | EN No. | ASTM UNS-No. |

|---|---|---|---|

| High Density (HD) | - | - | - |

| Molybdän (Mo) | - | - | - |

| Molybdän-Lanthan (ML) | - | - | - |

| Niob (Nb) | - | - | - |

| Rhenium (Re) | - | - | - |

| Tantal (Ta) | - | - | - |

| Titan (Ti) | - | - | - |

| Titan-Zirkon-Molybdän (TZM) | - | - | - |

| Wolfram (W) | - | - | - |

| Wolfram-Kupfer (TUCO) | - | - | - |

| Wolfram-Rhenium | - | - | - |

| Zirkonium (Zr) | - | - | - |

Materials

For a more sustainable future in construction.

With its 100 % share of recycled material, the cuprolife copper tube makes a sustainable difference, and thus makes a significant contribution to the advancement of building and construction as well as building services.

Every cuprolife tube from Wieland is manufactured in keeping with the mass balance approach – using a process with 100 % recycled copper. As the starting point when verifying cuprolife, TÜV SÜD tested the procedure for calculating the 100 % recycled content*.

The new standard in copper tubes: cuprolife®.

Thanks to cutting-edge manufacturing techniques, cuprolife tubes exceed even the highest requirements. Optimal efficiency and reliability are guaranteed along with an exceptional service life. cuprolife tubes are universally usable. cuprolife is permanently in stock and can be supplied in any size from 6 x 1 mm to 159 x 3 mm.

Fields of application

- Domestic hot and cold water supply

- Heating

- Gas

- Liquid gas

- Heating oil / biofuel oil B10

- Solar systems

- Rainwater

- Industrial compressed air

- Sprinkler systems

- Firefighting systems

Technical features

- 100 % recycled copper*

- Design according to EN 1057, quality assured

- Made of pure copper Cu-DHP

- With quality mark and DVGW certification: DV-7204AU2106 (6 to 159 mm outside diameter)

- Universal use in a range of finely differentiated dimensions

- Optimum availability and compatibility with a wide range of fittings

- Maximum operating temperature at 10 bar operating pressure: 250 °C (applies to dimensions up to DN 150)

- Fire resistance: EN 13501-1 – A1 (nonflammable)

- Dimensions according to DVGW GW 392 (6 to 159 mm) with closed tube ends

- For optimal drinking water hygiene

*Mass balance approach, based on ISO 14021, verified by TÜV SÜD.

Reliable for all areas of home installation

For many years, installers have been relying on SANCO branded copper tubes. The tubes are very reliable, suitable for all areas of domestic installation and have more than proven their worth in practice. Whether drinking water supply (hot and cold), heating systems, oil, gas and liquid gas supplies as well as thermal solar systems: Wieland SANCO tubes are always the right choice and, of course, covered by the relevant regulations.

Technical features

- Patented manufacturing process: SANCO tubes are significantly better than required by standards and regulations.

- Design according to EN 1057, quality assured

- Made of pure copper Cu-DHP

- With quality mark and DVGW certification:

DV-7204AU2106 (12 to 159 mm outside diameter). - Universal use in a range of finely differentiated dimensions

- Optimum availability and compatibility with a wide range of fittings

- Maximum operating temperature: 250 °C

- Fire resistance: EN 13501-1-A1 (non-flammable)

- Dimensions according to DVGW GW 392 (12 to 159 mm) with closed tube ends

- For optimal drinking water hygiene

- Wide range of certifications available, such as Kitemark, Afnor, KIWA, DVGW and many others

Fields of application

- Domestic hot and cold water supply

- Heating systems

- Gas and oil services for heating and cooking

- Solar systems

- Rainwater

- Industrial compressed air

- Sprinkler and Fire-fighting-systems

- Further applications in consultation with our technical advisory service

| Wieland | EN Designation | EN No. | ASTM UNS-No. |

|---|---|---|---|

| K18/K32 | Cu-ETP | CW004A | C11000 |

| K20/K21/K28 | Cu-DHP | CW024A | C12200 |

| Wieland | EN Designation | EN No. | ASTM UNS-No. |

|---|---|---|---|

| Elmedur NCS | CuNi2SiCr* | ~CW111C* | C18000 |

| Elmedur X | CuCrZr | CW106C | C18150 |

| Wieland | EN Designation | EN No. | ASTM UNS-No. | JIS-No. | Temper |

|---|---|---|---|---|---|

| Z11 | CuZn35Pb1 | CW600N | C34000 | ||

| Z21 | CuZn38Pb2 | CW608N | C3713 | extruded/drawn | |

| Z31/Z41/Z48 | CuZn40Pb2 | CW617N | C38000 | extruded/drawn | |

| Z31/Z41/Z48 | CuZn40Pb2 | CW617N | C38000 | ||

| Z31/Z41/Z48 | CuZn40Pb2 | CW617N | C38000 | ||

| Z32/Z33 | CuZn39Pb3 | CW614N | C38500 | ||

| Z32/Z33 | CuZn39Pb3 | CW614N | C38500 | ||

| Z45/Z46 | CuZn36Pb2As | CW602N | C35330 |

| Wieland | EN Designation | EN No. | ASTM UNS-No. | JIS-No. | Temper |

|---|---|---|---|---|---|

| M32 | - | - | C26000 | ||

| M37/M38 | CuZn37 | CW508L | C27200 | C2720 | |

| M37/M38 | CuZn37 | CW508L | C27200 | C2720 | |

| eco M43® | CuZn38As | CW511L | C27453 | ||

| eco M57® | CuZn42 | CW510L | - | extruded/drawn |

| Wieland | EN Designation | EN No. | ASTM UNS-No. |

|---|---|---|---|

| S40 | CuZn37Mn3Al2PbSi | CW713R | C67420 |

| Wieland | EN Designation | EN No. | ASTM UNS-No. |

|---|---|---|---|

| B12/B21 | CuSn8P/CuSn8 | CW459K/CW453K | C52100 |

| Wieland | EN Designation | EN No. | ASTM UNS-No. |

|---|---|---|---|

| A05 | Al99,5 | AW-1050A | - |

| A13 | AlMg3 | AW-5754 | - |

| A22 | AlMgSi | AW-6060 | - |

| A32 | AlSi1MgMn | AW-6082 | - |

| A66 | - | - | - |

| A76 | - | - | - |

| Wieland | EN Designation | EN No. | ASTM UNS-No. |

|---|---|---|---|

| K18/K32 | Cu-ETP | CW004A | C11000 |

| Wieland | EN Designation | EN No. | ASTM UNS-No. |

|---|---|---|---|

| Elmedur X | CuCrZr | CW106C | C18150 |

| Wieland | EN Designation | EN No. | ASTM UNS-No. | JIS-No. |

|---|---|---|---|---|

| Z12 | CuZn35Pb2 | CW601N | C34200 / C34500 | |

| Z21 | CuZn38Pb2 | CW608N | C3713 |

Capabilities

Surface plating

We ensure that your material is foil coated or surface plated. In cooperation with certified surface platers, we offer you strip, sheet and sections in various alloys with different surfaces.

For further information please contact us.

Value-added processing/cutting to length

Through the use of state-of-the-art automatic sawing machines, we offer you, upon request, to deliver rod sections in cut lengths with the closest cutting tolerances. To optimise your material input we supply you with cut to length plates with the closest tolerances.

For further information please contact us.

Logistics

Our comprehensive inventory and excellent contacts with leading international manufacturers as well as the use of state-of-the-art storage technology allow for just-in-time deliveries.

As a mediator between production and further processing, our processes are continuously adjusted and optimised according to customer requirements, with high product quality and on-time delivery having top priority.

For further information please contact us

Recycling

Recycling management will increasingly gain in importance. We promote environmentally friendly production by collecting material waste that has been generated in your production.

For the collection of your waste, we put small containers of 0.5 m³ at your disposal free of charge. For larger amounts of waste, containers of 10 m³ are available to you. Scrap is systematically turned into raw material for new, high-quality semi-finished products. By recycling the waste material and subsequent remelting, the cycle of imperishable metals is closed.

Benefit from our attractive conversion conditions.

For further information please contact Birgit Krause.

Resources

Information material and important documents for download

Wieland Group

431.49 KB

High strength Aluminium Bronze and special copper alloys | wieland prometa

989.23 KB

AI and AI alloys

459.69 KB

wieland duro

815.16 KB

wieland duro

648.55 KB

147.73 KB

148.39 KB

Purchasing, stocking and selling of copper alloys and refractory metals

1.88 MB

185.48 KB

1.88 MB

Wieland Group

429.19 KB

Rolled Products

4.33 MB

WICONNEC

3.07 MB

Copper alloys for drinking water applications

6.89 MB

Copper alloys for drinking water applications

6.89 MB

Rolled Products

1.92 MB

Stock Program Vöhringen

2.01 MB

Lagerprogramm Vöhringen

2.01 MB

Wieland Metal Services Germany

61.48 KB

Wieland Metal Serivces Germany GmbH

69.15 KB

1.63 MB

ecoline_Die-bleifreien-Legierungen

5.62 MB

ecoline_The-lead-free-alloys

5.6 MB

1.7 MB

1.7 MB

Wieland Metal Services Germany

138.55 KB

6.52 MB

2.76 MB

2.7 MB

Contact person

Get in touch - Your contact person at Wieland Metal Services Germany GmbH

![]() Christoph Altrichter

Christoph Altrichter

Managing Director

Wieland Metal Services Germany GmbH

Send email

![]() Nico Weisser

Nico Weisser

Sales Director | Trossingen

Wieland Metal Services Germany GmbH

+49 7425 947 26

Send email

Chantal Degenhardt

Chantal Degenhardt

Sales Director | Hagen

Wieland Metal Services Germany GmbH

+49 2334 9603 11

Send email

Robert Pautzsch

Robert Pautzsch

Sales Director | Dresden

Wieland Metal Services Germany GmbH

+49 162 7606518

Send email

Markus Wagner

Markus Wagner

Sales | Ingolstadt

Wieland Metal Services Germany GmbH

+49 152 57933473

Send email

Ariane Gertzmann

Ariane Gertzmann

Sales Director | HPA Europe

Wieland Metal Services Germany GmbH

+49 172 3410976

Send email

Wieland Metal Services Germany GmbH

Graf-Arco-Straße 36

89079 Ulm

Germany

Managing Director:

Christoph Altrichter

Court of Registration: Ulm HRB 745718

VAT Identification Number: DE358435645

Career

Start your career at Wieland Metal Services Germany GmbH

Unleash potential.

Already know your search term? Then go ahead and use our full text search. You will get a list of all relevant results.