Wieland Cimsa S.A.

- Surfaces and Coatings

- Stockholding

- Transportation

- Metal processing (cutting)

- Recycling

Organization

08130 Santa Perpètua de Mogoda

Spain (UTC+1)

07:00 am – 04:00 pm

Friday

07:00 am – 02:30 pm

06:00 am – 09:00 am

09:30 am – 01:00 pm

Metal Information

Current metal prices

Products

Our products at a glance

Product categories

Headline

Back to product overviewEnhanced surface tubes

Low-finned tubes

Medium-high finned tubes

High finned tubes

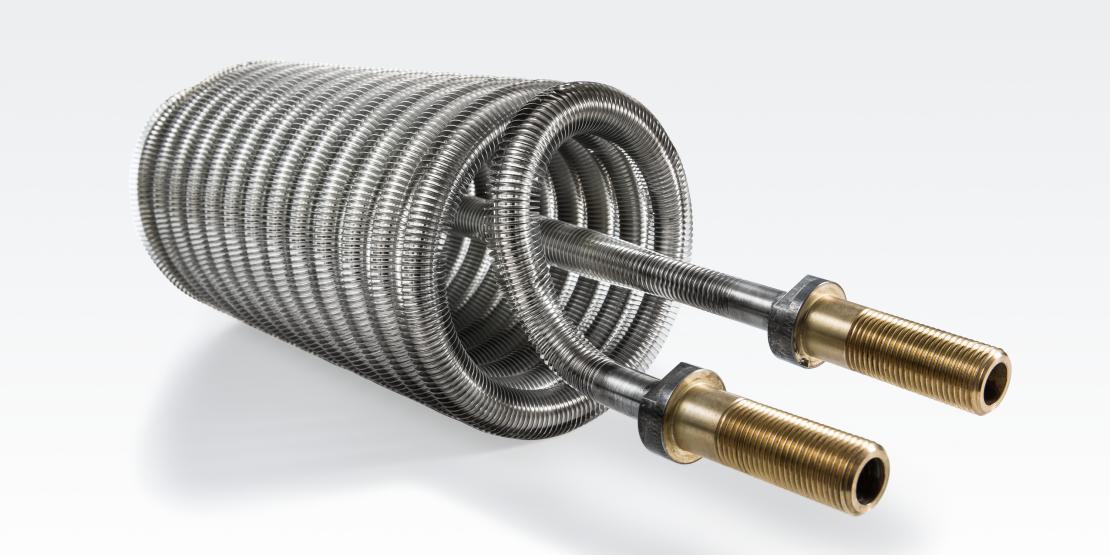

Coaxial heat exchanger WKE | WKC

Wieland WRK

Finned tube heat exchanger WRW

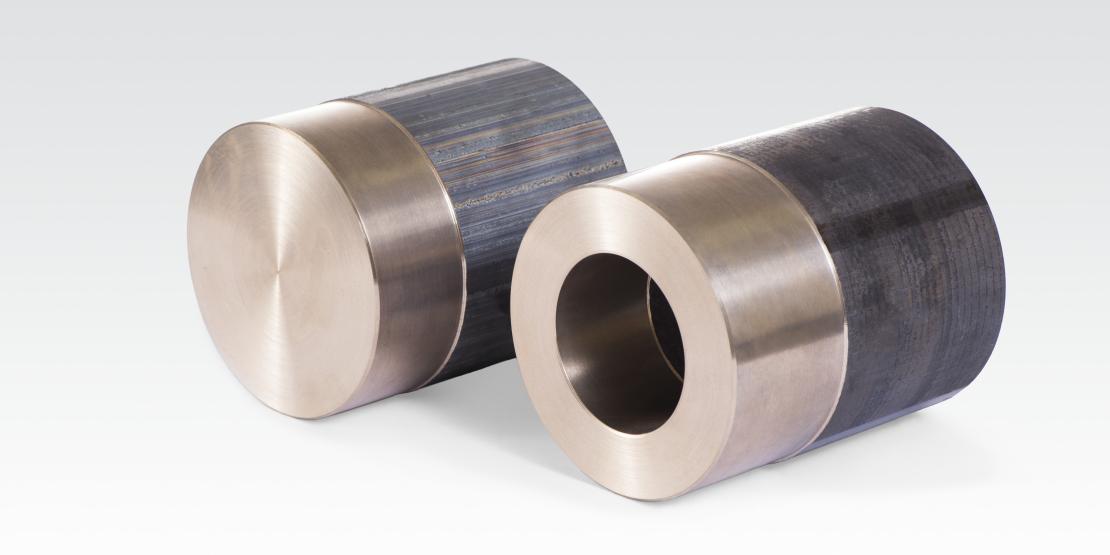

Ingots

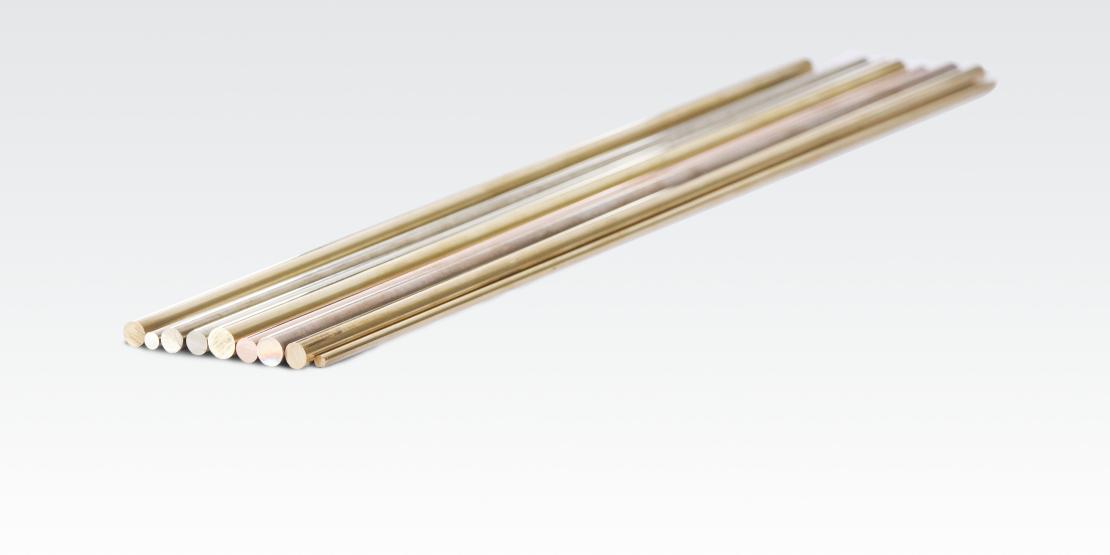

Rods

Sectional rod

Machining

WICONNEC®

ecoline®: Lead-free solutions

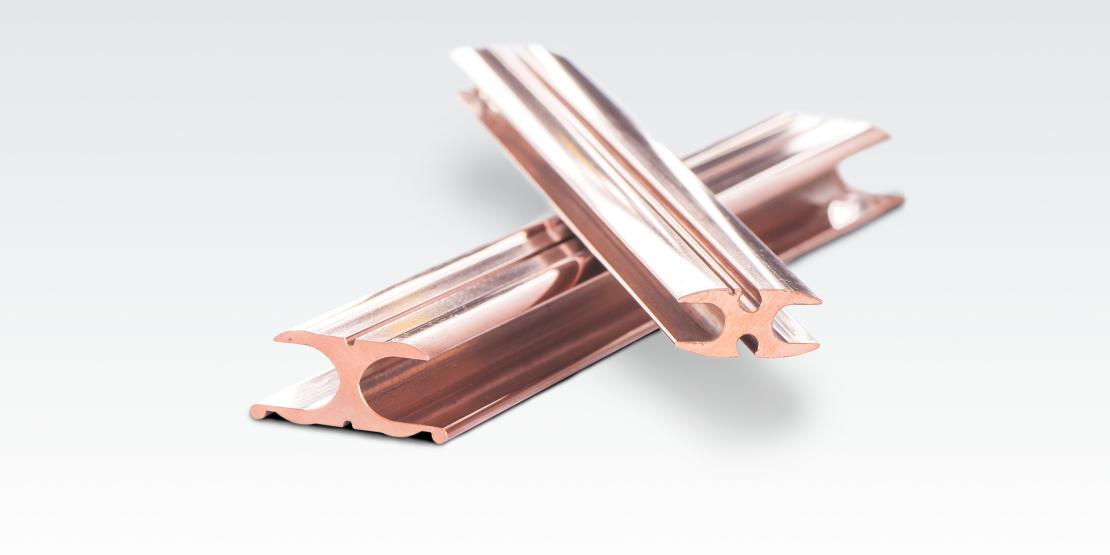

Precision continuous casting

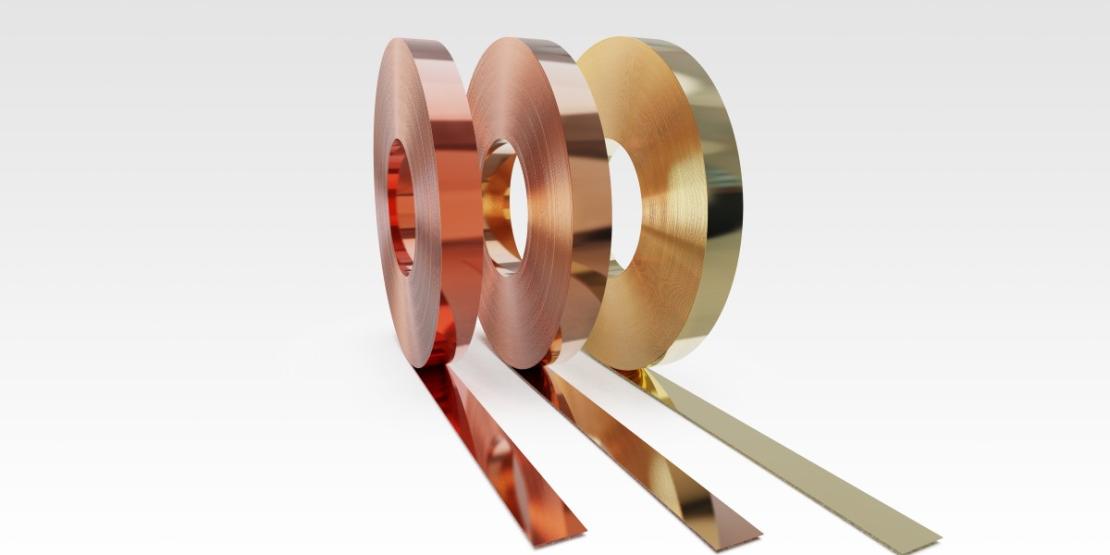

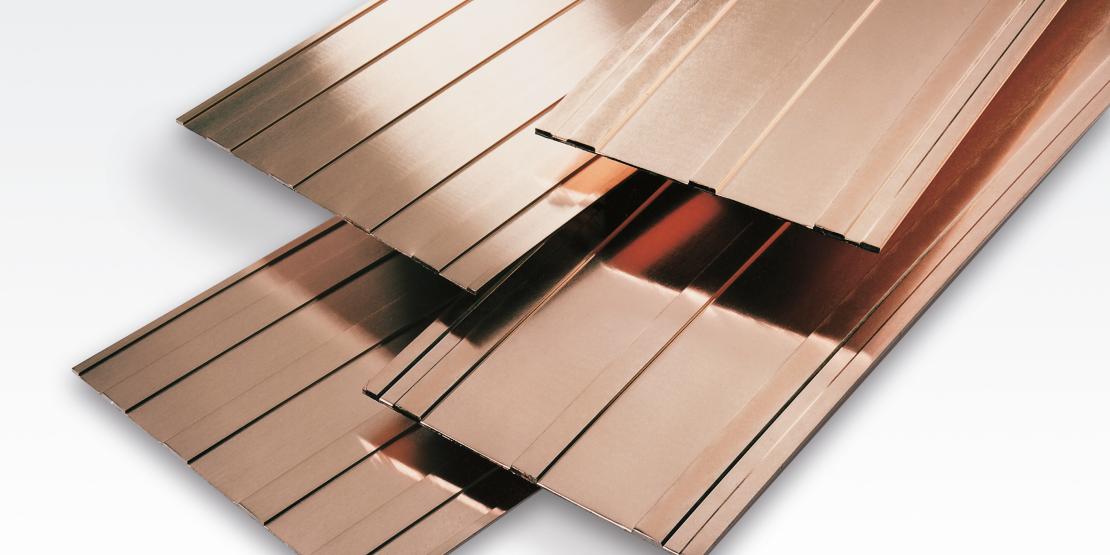

Strip

Multi-gauge strip

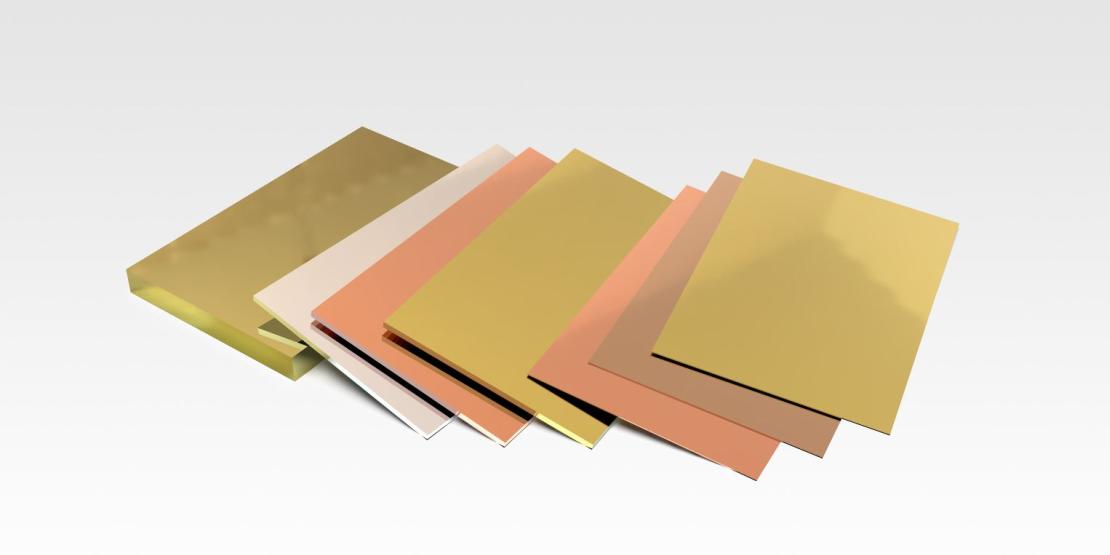

Sheets and Plates

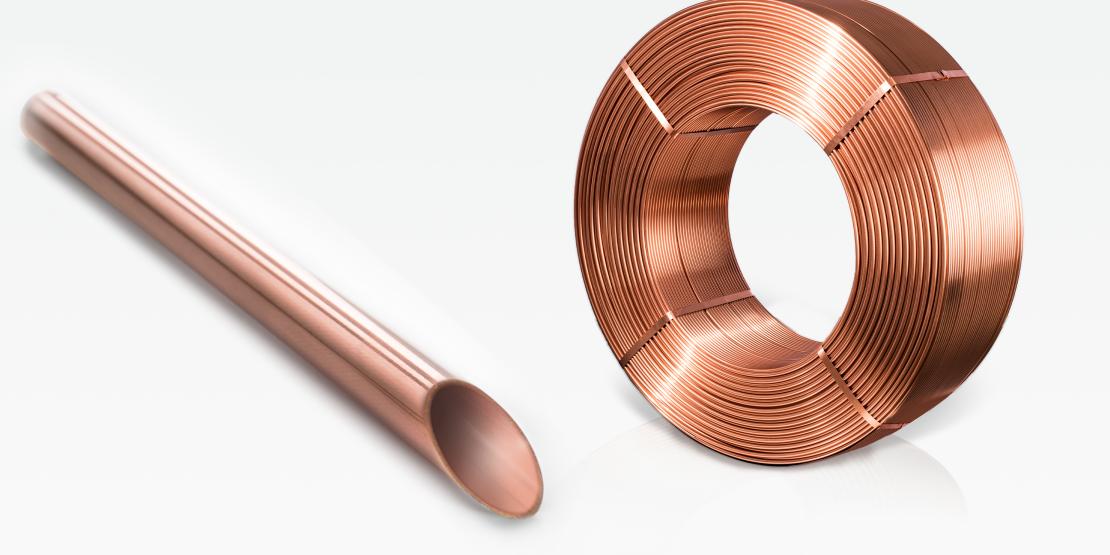

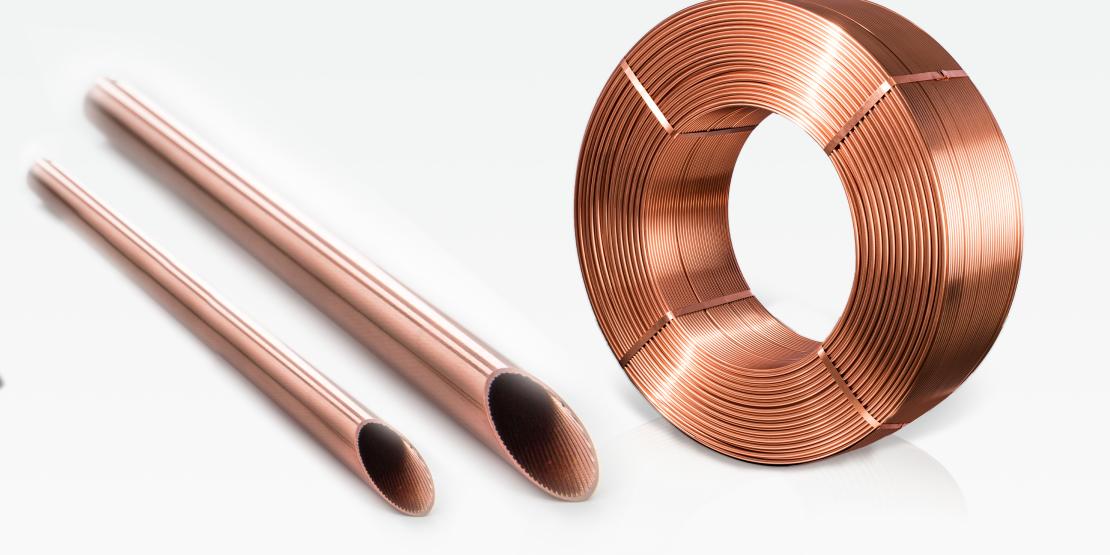

Smooth industrial tubes

Innergrooved industrial tubes

Plumbing tubes

Refrigeration and medical gas tubes

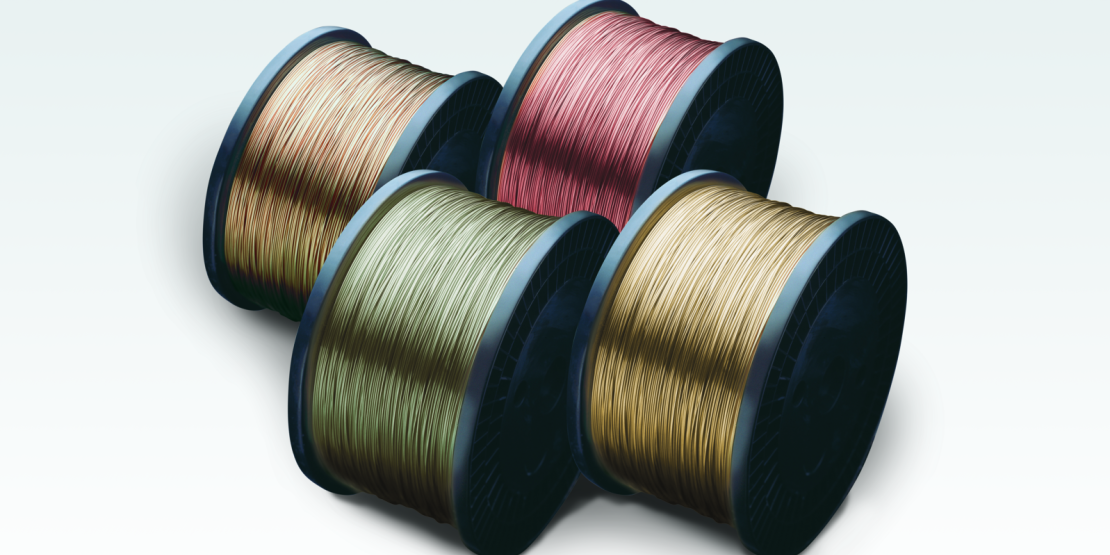

Wire

Optimised heat transfer for your shell-and-tube heat exchanger

The enhanced surface tubes made by Wieland Thermal Solutions have been optimized for use as condenser or evaporator tubes in shell-and-tube heat exchangers used in the refrigeration and air-conditioning industry. These can be designed to be much more compact, saving you energy, installation space, and materials.

Your advantages at a glance

- Significantly higher heat transfer coefficients than smooth or low finned tubes

- More compact and lighter heat exchangers

- Significantly reduced filling quantities of e.g. refrigerants

- Highest efficiencies due to smallest temperature differences

- Precise thermal design with ThermalX

Optimized heat transfer for your shell-and-tube heat exchanger

The enhanced surface tubes made by Wieland Thermal Solutions have been optimized for use as condenser or evaporator tubes in shell-and-tube heat exchangers used in the refrigeration and air-conditioning industry. These can be designed to be much more compact, saving you energy, installation space and materials.

Our Materials

We offer you a broad portfolio of materials and can expand our offerings at any time to meet your specific needs regarding thermal conductivity, mechanical properties, or corrosion resistance. Enhanced surface tubes made by Wieland Thermal Solutions are already available in copper, copper-nickel, brass, carbon steel, stainless steel, and titanium.

You can find more product information here

For extreme efficiency in a variety of applications

Low-finned tubes are a reliable solution for controlling the temperature of gases and liquids, or for evaporating and condensing refrigerants. Thanks to their larger heat transfer surface area, they offer considerable potential to save in terms of materials and fill volumes. The wide range of dimensions offered by Wieland Thermal Solutions makes these products perfect for a broad scope of applications in the refrigeration and air conditioning industry, for oil/gas coolers in machinery and plant engineering, and for intermediate vapor superheaters in process engineering.

Your advantages at a glance

- Proven solution in a wide range of applications

- Increased heat transfer surface compared to plain tubes

- Material savings due to reduced tube length

- Filling quantity reduction due to higher efficiency

Our Materials

We offer you a broad portfolio of materials and can expand our offering at any time to meet your specific needs regarding thermal conductivity, mechanical properties, or corrosion resistance. Low-finned tubes made by Wieland Thermal Solutions are already available in copper, copper-nickel, brass, carbon steel, stainless steel, and titanium.

You can find more product information here

GEWA-K/KS

S/T Trufin & TurboChil in Steel

S/T Trufin & TurboChil in Titanium

For compact coils and bent shapes

Medium-high finned tubes feature a significantly larger heat transfer surface area compared to plain tubes. They are ideal for compact and high-performance coils and shell-and-tube heat exchangers. Wieland medium-high finned tubes are a proven and robust solution for water heaters, storage tanks, refrigerant condensers, oil coolers, gas coolers or safety heat exchangers and more.

Your advantages at a glance

- High surface enlargement compared to plain tubes

- Ideal for compact and robust heat exchangers

- Excellent bending properties and processability

- Availability of various dimensions, internal structures and materials

Our Materials

We offer the widest range of material in the industry and can extend it on request in case of special requirements for heat conductivity, mechanical properties or corrosion resistance. Medium-high finned tubes from Wieland Thermal Solutions are available in copper, copper-nickel, aluminium and carbon steel as well as in stainless steel in limited range.

You can find more information here

For highest efficiency in controlling the temperature of gases and liquids

High-finned tubes have a much greater outer surface area than smooth tubes. This allows for particularly compact designs. Thanks to their high, thin fins, these tubes perform particularly well in the heating and cooling of liquids and gases, making them an excellent choice for applications in heating technology, as well as in machinery and plant engineering.

Your advantages at a glance

- Highest surface enlargement compared to plain tubes (up to factor 18)

- Enables particularly compact and robust designs

- Available in straight lengths or as coiled heat exchanger

- Also available as bimetallic version GEWA-HB

Our Materials

We offer you a broad portfolio of materials and can expand our offering at any time to meet your specific needs regarding thermal conductivity, mechanical properties, or corrosion resistance. High-finned GEWA-H tubes made by Wieland Thermal Solutions are already available in copper, copper-nickel and aluminum.

In the GEWA-HB tube materials like carbon steel, stainless steel, titanium or almost any other material like brass and nickel can be used for the inner tube.

You can find more information here

In coaxial heat exchangers, fluids are ideally conducted in counter-flow directions. The Wieland WKE and WKC series have been optimized for the condensation or evaporation of refrigerants and are used in reciprocating chillers and heat pumps.

Your advantages at a glance

- High specific power due to optimized inner tubes

- Flow guidance in counterflow

- Insensitive to frost

- Low fouling tendency

- Long service life

- Reversible operation possible

- Standard designs from stock

You can find more information here

Data sheet WKC | WKE

Our wholesaler for standard heat exchanger

Calculate your coaxial heat exchanger directly online:

ThermalX

WRK finned tube heat exchangers are suitable for efficient direct condensation and evaporation in heat pump buffer tanks. The inner grooved surface of the used finned tubes optimize the heat transfer. Thus highest COP-values are possible even with smallest temperature differences.

Your advantages at a glance

- Efficient: Highest COP values due to direct integration of the heat exchanger in the storage tank

- Filling volume optimized: Smallest refrigerant volumes due to compact design

- Easy handling: Easy replacement and maintenance

You can find more information here

Storage heating, circulation heating of domestic water, protecting solid fuel boilers from overheating, or controlling the temperature of oils and emulsions: With our WRW series of heat exchangers, you are putting your trust in highly developed, compact solutions that are ready to install.

Your advantages at a glance

- Compact design due to high thermal conductivity of copper combined with increased heat transfer area

- Proven corrosion resistance

- Retrofittable due to compact spiral design

- Standard designs from stock

You can find more information here

Ecocast Properties

Wieland | EN Designation | EN-No. | ASTM-UNS-No. |

|---|---|---|---|

CuZn21Si3P-C | CC768S | C87850 | |

| CuZn21Si3P-B | CB768S |

|

High mechanical strength

Its grain refiner ensures an extremely fine grain size, facilitating even distribution of force throughout the entire structure. The result: strength and hardness otherwise only known in steel, even with thin, weight-reducing wall thicknesses.

Improved casting

Thanks to its fine-grained structure, Ecocast is ideal for filigree components.

Reduced waste

In every situation where you were previously dependent on red brass for filigree shapes, the high amount of waste of this conventional material is eliminated with Ecocast.

Excellent machinability

Ecocast and its special chemical composition also makes reworking cast parts through machining, grinding, polishing, or coating safe, precise, and cost-effective.

Top-rate corrosion resistance

The fine-grained structure through and through also means minimal dezincification on the surface due to touching, oxidation, or cleaning.

The future is lead-free

Secure your market lead: with Ecocast you can design and equip your products for the future, too. After all, many countries and various customers are already implementing strict regulations concerning the use of lead-free materials.

Universal

Ecocast can be cast both in ingot molds and in sand. The material is standardized under CC768S in EN 1982.

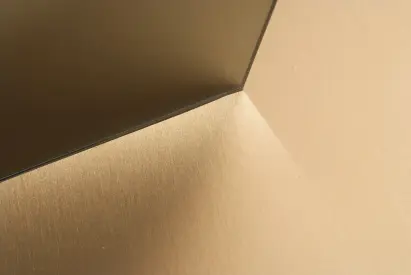

Ecocast: The New Material for Sanitary Installations

Ecocast is the perfect material for sanitary installations, not just for meeting drinking water regulations in the future, but also mainly for meeting current cost-efficiency requirements. Thanks to its high mechanical strength, Ecocast achieves wall thicknesses that help significantly reduce weight and save on materials and costs without compromising on stability. Moreover, Ecocast can handle forces (or moments) that until now have only been reserved for steel. The fine-grained structure and lack of lead produce surfaces that are aesthetically impeccable when Ecocast parts are coated.

Functional Properties, Long-Lasting Look

The extremely corrosion-resistant brass material Ecocast has a premium golden surface that is especially long -lasting, making it suitable even for frequently used objects and room fixtures made from cast parts. Ecocast also has high color stability and resistance to degradation caused by contact, air humidity, or intensive cleaning, which increases hygiene safety in hospitals, clinics, and nursing care institutions. - The innovative cast material from Wieland retains its functional properties even with heavy day-to-day use.

Materials

| Wieland | EN Designation | EN No. | ASTM UNS-No. |

|---|---|---|---|

| K08 | Cu-OFE | CW009A | C10100 |

| K12 | Cu-HCP | CW021A | C10300 |

| K18/K32 | Cu-ETP | CW004A | C11000 |

| K20/K21/K28 | Cu-DHP | CW024A | C12200 |

| K30 | Cu-OF | CW008A | C10200 |

| Wieland | EN Designation | EN No. | ASTM UNS-No. |

|---|---|---|---|

| K41 | CuNi1Pb1P* | - | C19150 / C19160 |

| K52 | CuNi2Si | CW111C | C70260 |

| K53 | CuNi2SiS* | - | - |

| K54 | CuNi2SiCr* | - | C81540 |

| K60 | CuCr1Zr | CW106C | C18150 |

| K61 | CuCr1Zr | CW106C | C18200 |

| K65 | CuFe2P | CW107C | C19400 |

| K81 | CuSn0,15 | CW117C | C14415 |

| KC1 | CuPb1P | CW113C | C18700 |

| eco KS2® | CuSP | CW114C | C14700 |

| Wieland | EN Designation | EN No. | ASTM UNS-No. | JIS-No. |

|---|---|---|---|---|

| Z11 | CuZn35Pb1 | CW600N | C34000 | |

| Z12 | CuZn35Pb2 | CW601N | C34200 / C34500 | |

| Z14 | CuZn37Pb2 | CW606N | C35300 | |

| Z21 | CuZn38Pb2 | CW608N | C3713 | |

| Z23 | CuZn36Pb3 | CW603N | C36000 | |

| Z29 | CuZn39Pb2 | CW612N | C37700 | |

| Z31/Z41/Z48 | CuZn40Pb2 | CW617N | C38000 | |

| Z32/Z33 | CuZn39Pb3 | CW614N | C38500 | |

| Z40 | CuZn43Pb2Al | CW624N | - | |

| Z43 | CuZn33Pb1AlSiAs | CW725R | - | |

| Z45/Z46 | CuZn36Pb2As | CW602N | C35330 |

| Wieland | EN Designation | EN No. | ASTM UNS-No. |

|---|---|---|---|

| L10/L13/L15 | CuNi10Fe1Mn | CW352H | C70600 |

| L30 | CuNi30Mn1Fe | CW354H | C71500 |

| Wieland | EN Designation | EN No. | ASTM UNS-No. | JIS-No. |

|---|---|---|---|---|

| M10 | CuZn10 | CW501L | C22000 | C2200 |

| M15/M16/M17 | CuZn15 | CW502L | C23000 | |

| M30/M34 | CuZn30 | CW505L | C26000 | C2600 |

| M36 | CuZn36 | CW507L | C26800 / C27000 | C2700 |

| M37/M38 | CuZn37 | CW508L | C27200 | C2720 |

| eco M43® | CuZn38As | CW511L | C27453 | |

| eco M57® | CuZn42 | CW510L | - | |

| eco M58® | CuZn42 | CW510L | - |

| Wieland | EN Designation | EN No. | ASTM UNS-No. |

|---|---|---|---|

| S40 | CuZn37Mn3Al2PbSi | CW713R | C67420 |

| eco S34® | CuZn34Mn2SiAlNi* | - | C67340 |

| eco ST2 | CuZn35Sn1P | CW727R | - |

| eco ST3 | CuZn29Si1SnP | CW729R | - |

| eco ST4 | CuZn42 | CW510L | - |

| eco SW1® | CuZn21Si3P | CW724R | C69300 |

| eco SZ2® | CuZn36Si1P | CW726R | C68370 |

| eco SZ3® | CuZn40SiP | CW728R | - |

| eco SZ4® | CuZn42 | CW510L | C28500 |

| eco SZ5® | CuZn40 | CW509L | C27450 |

The closer the input stock approaches the end product, the higher the efficiency of downstream machining. The Wieland E5006 precision hexagon rod fulfils these expectations in a quite special way: It presents the precise outer contours of a workpiece. Unlike machined multiedge cross sections, drawn edged rods are characterised by extremely smooth, plane, and compacted surfaces. Moreover, they lend the workpiece a continuous grain structure of high impact toughness. Obvious material savings are yet another benefit.

Learn more

W5006 precision brass rods

Our W5000 round rods are our premium product for your high performance machining operations. We guarantee the minimum diameter variance in the one batch and a straightness of 0.55 mm/m up to a diameter of 80 millimetres. And best of all: tight alloying tolerances for consistent machining results. Fine, uniform lead distribution for top machinability. Low contamination levels and optimised phase distribution for long tool lives.

Learn more

W5000 precision brass rods

The Wieland WICONNEC brand offers a range of copper materials in the form of rods and wires that are ideal for machined sockets and pins for plug connectors. This material portfolio also offers brass materials in addition to specially developed copper alloys for complex turned plug connectors.

Learn more about

Wieland ecoline

From Europe’s largest copper alloy foundry in Vöhringen/Iller (Germany), we can offer you far in excess of a hundred different copper materials. These include not only a wide range of continuous castings like tubes and rods, but also shaped rods and sections of complex geometries. At the same time, our flexibility ensures the prompt realisation of your special custom wishes.

Materials

Learn more

Strips for connector

Hot dip tinned copper and copper-alloy strip

Strip for semiconductor packages

Materials

| Wieland | EN Designation | EN No. | ASTM UNS-No. | JIS-No. |

|---|---|---|---|---|

| K09 | Cu-OFE | CW009A | C10100 | C1011 |

| K11 | Cu-OF | CW008A | C10200 | |

| K12 | Cu-HCP | CW021A | C10300 | |

| K14 | Cu-PHC | CW020A | C10300 | |

| K19 | Cu-DHP | CW024A | C12200 | C1220 |

| K32 | Cu-ETP | CW004A | C11000 | C1100 |

| Wieland | EN Designation | EN No. | ASTM UNS-No. |

|---|---|---|---|

| K65 | CuFe2P | CW107C | C19400 |

| K80 | CuFe0,1P* | - | C19210 |

| K81 | CuSn0,15 | CW117C | C14415 |

| Wieland | EN Designation | EN No. | ASTM UNS-No. |

|---|---|---|---|

| K55 | CuNi3Si1Mg* | - | C70250 |

| K57 | CuNi1Co1Si* | - | C70350 |

| K73 | CuNi1ZnSi* | - | C19005 |

| K75 | CuCrSiTi* | - | C18070 |

| K76 | CuNiSiP* | - | C19010 |

| K82 | - | - | C15100 |

| K88 | CuCrAgFeTiSi* | - | C18080 |

| Wieland | EN Designation | EN No. | ASTM UNS-No. | JIS-No. |

|---|---|---|---|---|

| M42 | CuZn42 | CW510L | - | |

| Z21 | CuZn38Pb2 | CW608N | C3713 | |

| Z30 | CuZn39Pb2 | CW612N | C37700 |

| Wieland | EN Designation | EN No. | ASTM UNS-No. | JIS-No. |

|---|---|---|---|---|

| M05 | CuZn5 | CW500L | C21000 | C2100 |

| M10 | CuZn10 | CW501L | C22000 | C2200 |

| M15 | CuZn15 | CW502L | C23000 | C2300 |

| M20 | CuZn20 | CW503L | C24000 | C2400 |

| M30 | CuZn30 | CW505L | C26000 | C2600 |

| M33 | CuZn33 | CW506L | C26800 | C2680 |

| M36 | CuZn36 | CW507L | C26800 / C27000 | C2700 |

| M37 | CuZn37 | CW508L | C27200 | C2720 |

| M38 | CuZn37 | CW508L | C27200 | C2720 |

| Wieland | EN Designation | EN No. | ASTM UNS-No. | JIS-No. |

|---|---|---|---|---|

| S12 | CuSn3Zn9 | CW454K | C42500 | C4250 |

| S23 | CuZn23Al3Co | CW703R | C68800 |

Learn more

Multi-gauge strip

| Wieland | EN Designation | EN No. | ASTM UNS-No. |

|---|---|---|---|

| K55 | CuNi3Si1Mg* | - | C70250 |

| K57 | CuNi1Co1Si* | - | C70350 |

| K73 | CuNi1ZnSi* | - | C19005 |

| K75 | CuCrSiTi* | - | C18070 |

| K76 | CuNiSiP* | - | C19010 |

| K82 | - | - | C15100 |

| K88 | CuCrAgFeTiSi* | - | C18080 |

| Wieland | EN Designation | EN No. | ASTM UNS-No. | JIS-No. |

|---|---|---|---|---|

| Z21 | CuZn38Pb2 | CW608N | C3713 | |

| Z30 | CuZn39Pb2 | CW612N | C37700 |

| Wieland | EN Designation | EN No. | ASTM UNS-No. | JIS-No. |

|---|---|---|---|---|

| M05 | CuZn5 | CW500L | C21000 | C2100 |

| M10 | CuZn10 | CW501L | C22000 | C2200 |

| M15 | CuZn15 | CW502L | C23000 | C2300 |

| M20 | CuZn20 | CW503L | C24000 | C2400 |

| M30 | CuZn30 | CW505L | C26000 | C2600 |

| M33 | CuZn33 | CW506L | C26800 | C2680 |

| M36 | CuZn36 | CW507L | C26800 / C27000 | C2700 |

| M37 | CuZn37 | CW508L | C27200 | C2720 |

| M38 | CuZn37 | CW508L | C27200 | C2720 |

Available materials

| Wieland | EN | EN-Nr. | UNS |

| K08 | Cu-OFE | CW009A | C10100 |

| K12 | Cu-HCP | CW021A | C10300 |

| K20 / K21 / K28 | Cu-DHP | CW024A | C12200 |

| K30 | Cu-OF | CW008A | C10200 |

| K65 | CuFe2P | CW107C | C19400 |

| L10 | CuNi10Fe1Mn | CW352H | C70600 |

| L30 | CuNi30Mn1Fe | CW354H | C71500 |

Delivery forms

- Level wound coils: 100 kg, 150 kg, 300 kg, 530 kg

- Straight lengths

- Rings

Materials

K65 - Sustainable and efficient

Sustainable and efficient – two keywords that have had a decisive impact on our time and have gained in relevance in recent years, especially in refrigeration. Increased environmental awareness in society and industry has therefore led to a kind of renaissance of natural refrigerants, especially CO2. Wieland supports this turnaround with a tube system that meets the high requirements of CO2 as a refrigerant.

Wieland K65 tubes have been designed for CO2 applications in the commercial field, especially that of supermarket refrigeration systems. Wieland K65 alloy provides the mechanical strength high enough to withstand the high operating pressures of CO2. At the same time, K65 tubes have outstanding processing properties, similar to those of standard copper (Cu-DHP/C12200).

All Wieland K65 tubes are available in the soft condition (R300/O61) to ensure excellent bending / flaring and collaring properties.

Wieland K65 tubes are offered from stock in two pressure ranges, 80 bar and 120 bar, and in dimensions ranging from 3/8” up to 2-1/8”.

Moreover, K65 tubes are also available in individual dimensions and different delivery forms.

For industrial processing, in particular CO2 heat exchanger (evaporator / gas cooler) manufacturing, level wound coils (LWC) are offered.

More K65 products in other categories

Your benefits

- Pressure resistance tailormade to your needs

- Cost reduction through weight reduction

- Proven processing technology: brazing instead of welding!

- Excellent heat transfer

- Design according to EN 14276 - TUEV or UL certification on demand

Typical applications

- Components of R744 refrigeration systems

- Fin coil heat exchangers for higher operation pressures (e.g. R744 evaporators or gas coolers )

- Shell and tube heat exchangers for higher operation pressures (e.g. R744 evaporators or gas coolers)

Technical properties

- Material: K65

- Conditions: soft R300/O61 and hard R420/H80

- Delivery form: Level wound coils or straight lengths

- Coil weights: 100 kg, 150 kg, 300 kg

- Available dimensions: 5 - 28 mm for LWC; 5 - 110 mm for straight lengths

- Usual standards: EN 12735-1 / EN 14276 / ASTM B 1017

Further information

cuproclima

For high-quality seamless inside smooth or innergrooved copper tubes in level-wound coils for the refrigeration and air-conditioning industries. The specified quality and inspection criteria exceed the existing requirements of standards (e. g. EN 12735-2, ASTM).

Your benefits

- longer run time for machines when uncoiling tubes

- reduced scrap for finished products

- reduced set-up time

- detection of even smaller surface defects on the tubes

- possible malfunctions of finished equipment during pressure testing are reduced

- fewer impurities in the refrigerant circuit.

Fields of application

- air-cooled heat exchangers for the air-conditioning and refrigeration industry

- evaporators

- condensers

- heat exchangers

- air coolers

Technical Properties

- Materials Cu-DHP

- Conditions soft and extra soft

- Delivery form level wound coils only

- Coil weights 100 kg, 150 kg, 300 kg

- Available dimensions 4 - 28 mm, wall thicknesses on request

Copper tubes with ultra clean inner surface for industrial applications

Our innovative production process for cuproclean tubes removes carbon film. This results in higher reliability, longer life and reduced maintenance costs.It is suitable for all fresh water applications. Copper offers outstanding versatility and is characterized by excellent formability as well as good processing properties. cuproclean copper tubes are also available in combination with other qualities such as cuproform.

Your benefits

- ultra-clean tube surface free from carbon film

- highest reliability and longer life also in fresh water applications

- best corrosion resistance

- carbon film test according to EN 1057 and confirmation in the certificate

Fields of application

- cooling ceilings

- solar water heating systems

- heat generators

Technical properties

- Materials Cu-DHP

- Conditions Soft

- Delivery form Level wound coils

- Coil weights 100 kg, 150 kg, 300 kg

- Available dimensions 6 - 28 mm, wall thicknesses on request

High formable copper tubes

In boiler manufacture, for example the tubes may be formed by: expanding, bending, upsetting and beading. Industrial copper tubes from conventional production do not always meet these high demands. Therefore, it is often necessary to use additional fittings made from other materials. This results in further production steps and consequently higher production costs.

Your benefits

- no special fittings necessary; this results in lower costs of production

- higher added value in your production

- exceptional forming properties – 80% expansion of the tube end tested and certified on the inspection certificate

- less scrap with very high deformation

Fields of application

- Connecting pieces, e.g. especially for boilers

Technical properties

- Materials Cu-DHP

- Conditions soft and extra soft

- Delivery form Layer-wound coils and straight lengths

- Coil weights 100 kg, 150 kg, 300 kg, 530 kg

- Available dimensions 6 - 28 mm for LWC; 6 - 64 mm for straight lengths

Copper tubes with high-purity outer surface for solar thermal applications

In the process of manufacturing solar heat absorbers requirements vary depending on the application. In the solarclean family you will find the most suitable copper tube quality for your optimized fabrication.

solarclean classic

The particularly clean tube surface ensures a high quality weld. You can therefore save at least one cleaning operation or an extensive pre-treatment of the components to be welded.

solarclean HP

For heat pipes in vacuum tube collectors - highest surface cleanliness on tube outside and inside prevents contamination of the heat transfer medium in the heat pipe and yet ensures the efficiency of the system.

solarclean plus

Improved forming properties for the fabrication of meander-shaped absorber tubes facilitate the setting of the bending machines and increase process reliability. solarclean_plus ensures super clean tube surfaces substantially improving the ultrasonic welding process.

solarclean eco

The cost-effective alternative for laser welding of absorber plate and tubing with sufficient cleanliness.

solarclean SL

Like solarclean classic, solarclean SL ensures superclean tube surfaces. Depending on your fabrication needs, you can also order solarclean in straight lengths.

Technical properties

- Materials Cu-DHP

- Conditions hard, hard relaxed, half-hard

- Delivery form Layer-wound coils and straight lengths

- Coil weights 100 kg, 150 kg, 300 kg, 530 kg

- Available dimensions 6 - 15 mm; wall thicknesses 0.3-1.2 mm

Available materials

| Wieland | EN | EN-Nr. | UNS |

| K20 / K21 / K28 | Cu-DHP | CW024A | C12200 |

| L10 | CuNi10Fe1Mn | CW352H | C70600 |

| K65 | CuFe2P | CW107C | C19400 |

Materials

K65 - Sustainable and efficient

two keywords that have had a decisive impact on our time and have gained in relevance in recent years, especially in refrigeration. Increased environmental awareness in society and industry has therefore led to a kind of renaissance of natural refrigerants, especially CO2. Wieland supports this turnaround with a tube system that meets the high requirements of CO2 as a refrigerant.

Wieland K65 tubes have been designed for CO2 applications in the commercial field, especially that of supermarket refrigeration systems. Wieland K65 alloy provides the mechanical strength high enough to withstand the high operating pressures of CO2. At the same time, K65 tubes have outstanding processing properties, similar to those of standard copper (Cu-DHP/C12200).

Innergrooved K65 tubes for manufacturing of CO2 heat exchangers (evaporator / gas cooler) are available in individual dimensions. These are delivered in level wound coils (LWC) or straight lengths alternatively.

Wieland K65 tubes are also available from stock in standard dimensions.

More K65 products in other categories

Your benefits

- Pressure resistance tailormade to your needs

- Cost reduction through weight reduction

- Proven processing technology: brazing instead of welding!

- Excellent heat transfer

- Design according to EN 14276 - TUEV certification on demand

Typical applications

- Fin coil heat exchangers for higher operation pressures (e.g. R744 evaporators or gas coolers)

- Shell and tube heat exchangers for higher operation pressures (e.g. R744 evaporators or gas coolers)

Technical properties

- Materials: K65

- Conditions: soft R300/O61 and hard R420/H80

- Delivery form: Level wound coils or straight lengths

- Coil weights: 100 kg, 150 kg, 300 kg

- Available dimensions: 5 - 16 mm

- Usual standards: EN 12735-1 / EN 14276 / ASTM B 1017

Further information

cuprofin-Standard

Wieland cuprofin-Standard tubes are effiecient heat exchanger tube that are suitable for one and two-phased flow as well as for evaporation and condensation. This enables the flexible production of efficient and compact heat exchangers. There is no need to keep a stock of different specialized tube types.

Your benefits

- improved heat transfer due to fin structure on the inside of the tube

- compact heat exchanger construction

- reduced material input

- Internal structure suitable for evaporation, condensation and single-phase heat transfer

cuprofin-standard is also available in superclean quality and as a microgroove tube.

Fields of application

- Finned heat exchangers for the refrigeration/air conditioning industry

- Evaporator

- Condensers

- Recooler

- Air Cooler

- Tube bundle injection evaporator

- Heat exchangers in the form of coiled elements (e.g. container heating and cooling)

Technical properties

- Delivery form Layer-wound coils and straight lengths up to 7,9m

- Coil weights 100 kg, 150 kg, 300 kg

- Usual standards

- EN 12735-2

- ASTM B359

- VdTÜV 420/6, 420/7

Further Information

cuprofin-C tubes for condensors

Wieland cuprofin-C Tubes are highly efficient heat transfer tubes for the tube-side condensation of refrigerants. Depending on the fluid used, the fins on the inside of the tube are optimized for high performance with low material usage. They enable the design of highly efficient and compact heat exchangers.

Your benefits

- optimized heat transfer due to adapted fin structure on the inside of the tube

- compact heat exchanger construction

- reduced refrigerant charge

- reduced material input

cuprofin-C is also available in superclean quality and as microgroove tube.

Fields of application

- Finned heat exchangers, especially condensers

- Heat exchangers in the form of coiled elements (e.g. container heating)

Technical properties

- Delivery form Layer-wound coils and straight lengths up to 7,9m

- Coil weights 100 kg, 150 kg, 300 kg

- Usual standards

- EN 12735-2

- ASTM B359

- VdTÜV 420/6, 420/7

Further Information

cuprofin-E tubes for evaporators

Wieland cuprofin-E tubes are highly efficient heat transfer tubes for the tube-side evaporation of refrigerants in finned heat exchangers. The fins on the inside of the tubes are designed for optimum performance during flow boiling and the lowest possible pressure drop for a wide range of refrigerants.

Your benefits

- optimized heat transfer due to adapted fin structure on the inside of the tube

- compact heat exchanger construction

- extremely low pressure drop

- reduced material input

cuprofin-E is also available in superclean quality and on requiry as a microgrooved tube.

Fields of application

- Finned heat exchangers, especially evaporators

Technical properties

- Delivery form Layer-wound coils and straight lengths up to 7,9m

- Coil weights 100 kg, 150 kg, 300 kg

- Usual standards

- EN 12735-2

- ASTM B359

- VdTÜV 420/6, 420/7

Further Information

cuprofin-EDX tubes for injection

cuprofin-EDX are highly efficient and stable heat exchanger rubes for Injection evaporator in tube bundle design.

Your benefits

- optimized heat transfer and very low pressure drop

- compact heat exchanger construction

- reduced material input

cuprofin-EDX is also available in superclean quality and on request as a microgroove tube.

Fields of applications

- Tube bundle injection evaporator

Technical properties

- Delivery form Layer-wound coils and straight lengths up to 7,9m

- Coil weights 100 kg, 150 kg, 300 kg, 530 kg

- Usual standards

- EN 12735-2

- ASTM B359

- VdTÜV 420/6, 420/7

Further Information

cuprofin-G tubes for single-phase heat transfer

Wieland cuprofin-G Tubes are highly efficient heat transfer tubes, especially designed for recooling systems and air coolers. The fins on the inside of the tubes are optimized for single-phase heat transfer of aqueous media such as water-glycol mixtures. This enables the production of efficient and compact heat exchangers.

Your benefits

- optimized heat transfer through adapted fin structure on the inside of the tube

- compact heat exchanger construction

- low pressure drop

- reduced material input

cuprofin-G is also available in superclean quality.

Fields of application

- Finned heat exchanger with single-phase heat transfer

- Recooler

- Air cooler

Technical properties

- Delivery form Layer-wound coils and straight lengths up to 7,9m

- Coil weights 100 kg, 150 kg, 300 kg

- Usual standards

- EN 12735-2

- ASTM B359

- VdTÜV 420/6, 420/7

Further Information

cuprofin-L10 tubes for seawater applications

Wieland cuprofin-L10 tubes are efficient heat transfer tubes which are particularly suitable for applications with seawater and other salt water as well as in their surroundings (e.g. coastal areas). The material CuNi10Fe1Mn (Wieland L10) is highly resistant to corrosion and erosion in these fluids. Compared to stainless steels the thermal conductivity of L10 is higher by a factor of approx. 3.

Your benefits

- improved heat transfer due to fin structure on the inside of the tube

- compact heat exchanger construction

- reduced material input

- highly resistant to corrosion and erosion

cuprofin-L10 is also available in superclean quality.

Fields of application

- Finned and bundle tube heat exchangers that are operated with seawater or other saltwater, or installed in coastal areas

Technical properties

- Delivery form Layer-wound coils and straight lengths up to 7,9m

- Coil weights 100 kg, 150 kg, 300 kg

- Usual standards

- EN 12735-2

- ASTM B359.

- VdTÜV 420/6, 420/7

Further Information

microgroove - Small diameter, high performance

With microgroove technology you build your heat exchanger with maximum efficiency and maximum compactness.

Your benefits

- reduced refrigerant charge

- Increased efficiency of the heat exchanger

- compact heat exchanger construction

- reduced material input

- reduced investment costs

microgroove is also available in superclean quality.

Fields of application

- Highly efficient finned heat exchangers

- Evaporator

- Condensers

Technical properties

- Delivery form Layer-wound coils and straight lengths up to 7,9m

- Coil weights 100 kg, 150 kg, 300 kg

- Usual standards

- EN 12735-2

- ASTM B359

- VdTÜV 420/6, 420/7

Further Information

Materials

For a more sustainable future in construction.

With its 100 % share of recycled material, the cuprolife copper tube makes a sustainable difference, and thus makes a significant contribution to the advancement of building and construction as well as building services.

Every cuprolife tube from Wieland is manufactured in keeping with the mass balance approach – using a process with 100 % recycled copper. As the starting point when verifying cuprolife, TÜV SÜD tested the procedure for calculating the 100 % recycled content*.

The new standard in copper tubes: cuprolife®.

Thanks to cutting-edge manufacturing techniques, cuprolife tubes exceed even the highest requirements. Optimal efficiency and reliability are guaranteed along with an exceptional service life. cuprolife tubes are universally usable. cuprolife is permanently in stock and can be supplied in any size from 6 x 1 mm to 159 x 3 mm.

Fields of application

- Domestic hot and cold water supply

- Heating

- Gas

- Liquid gas

- Heating oil / biofuel oil B10

- Solar systems

- Rainwater

- Industrial compressed air

- Sprinkler systems

- Firefighting systems

Technical features

- 100 % recycled copper*

- Design according to EN 1057, quality assured

- Made of pure copper Cu-DHP

- With quality mark and DVGW certification: DV-7204AU2106 (6 to 159 mm outside diameter)

- Universal use in a range of finely differentiated dimensions

- Optimum availability and compatibility with a wide range of fittings

- Maximum operating temperature at 10 bar operating pressure: 250 °C (applies to dimensions up to DN 150)

- Fire resistance: EN 13501-1 – A1 (nonflammable)

- Dimensions according to DVGW GW 392 (6 to 159 mm) with closed tube ends

- For optimal drinking water hygiene

*Mass balance approach, based on ISO 14021, verified by TÜV SÜD.

Reliable for all areas of home installation

For many years, installers have been relying on SANCO branded copper tubes. The tubes are very reliable, suitable for all areas of domestic installation and have more than proven their worth in practice. Whether drinking water supply (hot and cold), heating systems, oil, gas and liquid gas supplies as well as thermal solar systems: Wieland SANCO tubes are always the right choice and, of course, covered by the relevant regulations.

Technical features

- Patented manufacturing process: SANCO tubes are significantly better than required by standards and regulations.

- Design according to EN 1057, quality assured

- Made of pure copper Cu-DHP

- With quality mark and DVGW certification:

DV-7204AU2106 (12 to 159 mm outside diameter). - Universal use in a range of finely differentiated dimensions

- Optimum availability and compatibility with a wide range of fittings

- Maximum operating temperature: 250 °C

- Fire resistance: EN 13501-1-A1 (non-flammable)

- Dimensions according to DVGW GW 392 (12 to 159 mm) with closed tube ends

- For optimal drinking water hygiene

- Wide range of certifications available, such as Kitemark, Afnor, KIWA, DVGW and many others

Fields of application

- Domestic hot and cold water supply

- Heating systems

- Gas and oil services for heating and cooking

- Solar systems

- Rainwater

- Industrial compressed air

- Sprinkler and Fire-fighting-systems

- Further applications in consultation with our technical advisory service

Materials

cuprofrio.plus

Wieland branded copper tubes cuprofrio and cuprofrio.plus have a high level of internal cleanliness due to the individually closed tube ends and are suitable for refrigerants according to EN 12735-1.

cuprofrio tubes can be easily processed on site and conform to high quality standards with their extremely clean and dry inner surface. Close tube ends ensure the required quality even during storage and transportation.

learn more

cuprofrio.plus

cuprofrio.plus-tubes are insulated on the outside, which prevents nearly all water condensation on the outer surface of the tube.

Your benefits

- clean and dry inside surface

- standard dimensions available from stock

- good processing, easy joining, very easy to unwind and bend

- resistant, colour-fast insulation ensures consistent material properties in all weather conditions

- prevention of condensation water through insulating layer

- supplier traceability through signature

- compliance with Pressure Equipment Directive 97/23/EC

Fields of application

cuprofrio is suitable for technical gases and liquids, for example in

- chillers

- air-conditioning and refrigeration units

- heat exchangers

cuprofrio – refrigeration

Wieland branded copper tubes cuprofrio and cuprofrio.plus have a high level of internal cleanliness due to the individually closed tube ends and are suitable for refrigerants according to EN 12735-1.

cuprofrio tubes can be easily processed on site and conform to high quality standards with their extremely clean and dry inner surface. Close tube ends ensure the required quality even during storage and transportation.

learn more

Your benefits

- clean and dry inside surface

- closed tube ends in order to maintain cleanliness

- supplier traceability through signature

- standard dimensions available from stock

- good processing, easy joining, very easy to unwind and bend

- tube quality according to EN 12735-1

- compliance with Pressure Equipment Directive 2014/68/EU

Fields of application

cuprofrio is suitable for technical gases and liquids, for example in

- chillers

- air-conditioning and refrigeration units

- heat exchangers

Forms of delivery

- Coils (pancakes)

- Straight lengths of 5 m

cupromed – medical gas supply

The seamless drawn cupromed copper tube is used for refrigeration/air conditioning as well as for medical gas supply units according to EN ISO 7396-1. cupromed tubes in straight lengths meet the requirements according to EN 13348 and those according to EN 12735-1.

Your benefits

- clean and dry inside surface

- closed tubes ends keep the surface clean

- supplier traceability through signature

- standard dimensions available from stock

- good processing, easy joining, very easy to unwind and bend

- standard tube quality according to EN 12735-1

- compliance with Pressure Equipment Directive 2014/68/EU

- Requirements according to the PED/Pressure Equipment Directive 2014/68/EU

Fields of applications

cupromed is suitable for the transportation of technical gases and liquids as well as medical gas and vacuum in

- medical gas supply units

- refrigeration and air conditioning units

cuprogeo – geothermal energy

The seamless drawn cuprogeo tube is used for geothermal energy production. cuprogeo is designed for the use of refrigerants and gases for direct evaporation in heat pumps. The advantage of this application is that high performance can be achieved with suitable heat pumps.

Your benefits

- clean and dry inner surface

- supplier traceability through signature

- tube protected by an outside surface coating

- standard tube quality according to EN 12735-1

- requirements comply with the Pressure Equipment Directive 2014/68/EU

Fields of application

- geothermal energy

- refrigeration equipment and heat exchangers

- geothermal heat pumps with direct evaporation

K65 - Sustainable and efficient

two keywords that have had a decisive impact on our time and have gained in relevance in recent years, especially in refrigeration. Increased environmental awareness in society and industry has therefore led to a kind of renaissance of natural refrigerants, especially CO2. Wieland supports this turnaround with a tube system that meets the high requirements of CO2 as a refrigerant.

Wieland K65 tubes have been designed for CO2 applications in the commercial field, especially that of supermarket refrigeration systems. Wieland K65 alloy provides the mechanical strength high enough to withstand the high operating pressures of CO2. At the same time, K65 tubes have outstanding processing properties, similar to those of standard copper (Cu-DHP/C12200).

Wieland K65 tubes are offered from stock in two pressure ranges, 80 bar and 120 bar, and in dimensions ranging from 3/8” up to 2-1/8”.

All Wieland K65 tubes are available in the soft condition (R300/O61) to ensure excellent bending / flaring and collaring properties.

Other dimensions and delivery forms such as level wound coils are offered for industrial processing, in particular manufacturing of CO2 heat exchangers (evaporator/gas cooler).

More K65 products in other categories

Your benefits

- Cost reduction through weight reduction

- Proven processing technology: brazing instead of welding!

- Economical and safe installation of regrigeration systems with up to 120 bar operation pressure

- Excellent heat transfer

- Design according to EN 14276

Typical applications

- Pipelines for refrigeration systems, in particular for CO2 refrigerant, with an operation pressure of up to 120 bar

Technical properties

- Material: K65

- Operation pressure: 80 bar and 120 bar

- Condition: soft R300/O61

- Delivery form: straight lengths of 5 m

- Available dimensions: 9,52 - 53,97 mm (3/8" - 2-1/8")

- Tube ends: closed

- Usual standards: EN 14276 / EN 12735-1

Further information

Capabilities

Certification in accordance with ISO 9001:2015

Wieland Cimsa, S.A. was certified in accordance with ISO 9002 in 1997. In 2003, we were certified in accordance with ISO 9001:2000, and we have been certified in accordance with ISO 9001:2015 since 2015.

We are focused on excellence through quality, creating value for our customers and employees through innovation, technology, and operational skill.

We are committed to offering products and services that comply with legal and regulatory requirements and that meet the needs of our customers.

Strip-cutting services

We can help you to cut aluminum, steel, and other alloys

Recycling

Wieland Cimsa, S.A. is committed to the environment. Since May 2011, we have adhered to the waste management code (E-1235.11) of the Waste Agency of Catalonia to ensure the proper treatment of waste and the optimal use of nonferrous metal waste from our customers and suppliers, as well as the waste generated during our daily process with the aim of minimizing the environmental impact

We believe in managing the reuse of raw materials properly. For this reason, Wieland Cimsa promotes environmentally friendly production by recycling waste materials generated during its production processes. Wieland Cimsa provides and manages 1 m³ containers and offers attractive processing conditions.

Contact Mercè Burset

e-mail

Stockholding

Our extensive stockholding of drawn and rolled products, in both Copper and Copper alloys, combined with modern warehouse technology, enables us to provide Just in Time deliveries throughout Spain and Portugal.

Surfaces and Coatings

Our copper and copper alloys can be supplied in a wide range of surface coating.

Transport

Operating with our own vehicles for Catalunya ensures high quality service and flexible deliveries to the customers.

Resources

Information material and important documents for download

Wieland Cimsa, Barcelona

7.25 MB

Wieland-Werke AG, Ulm

49.2 KB

Wieland Cimsa

1.78 MB

Wieland-Werke AG, Ulm

138.18 KB

Wieland Cimsa

78.24 KB

Wieland Cimsa

670.17 KB

Wieland Cimsa

74.52 KB

Wieland Cimsa

62.02 KB

Wieland Cimsa

1.57 MB

Wieland Group

429.19 KB

Wieland Group

431.49 KB

Wieland Cimsa S.A.

c/ Berguedà, esq. Maresme

Polígono Can Bernades-Subirá

08130 Santa Perpètua de Mogoda

Barcelona

Espana

+34 93 544 6570

+34 93 574 3836

cimsa@wieland.com

Managing Director:

Rafael Rubio

Limited Company Headquarters: Sta. Perpètua de Mogoda, Spain

Registration: Barcelona, Spain

Registered no : 4120867

C.I.F. / VAT registration no.: A58033341

Career

Start your career at Wieland Cimsa S.A.

Unleash potential.

Already know your search term? Then go ahead and use our full text search. You will get a list of all relevant results.